Attaching the handle, Bleeding, Adding oil – Harbor Freight Tools 2-Ton Compact Floor Jack 68783 User Manual

Page 3: Lifting

SKU

68783

For technical questions, please call

1-800-444-3353

Page:

2

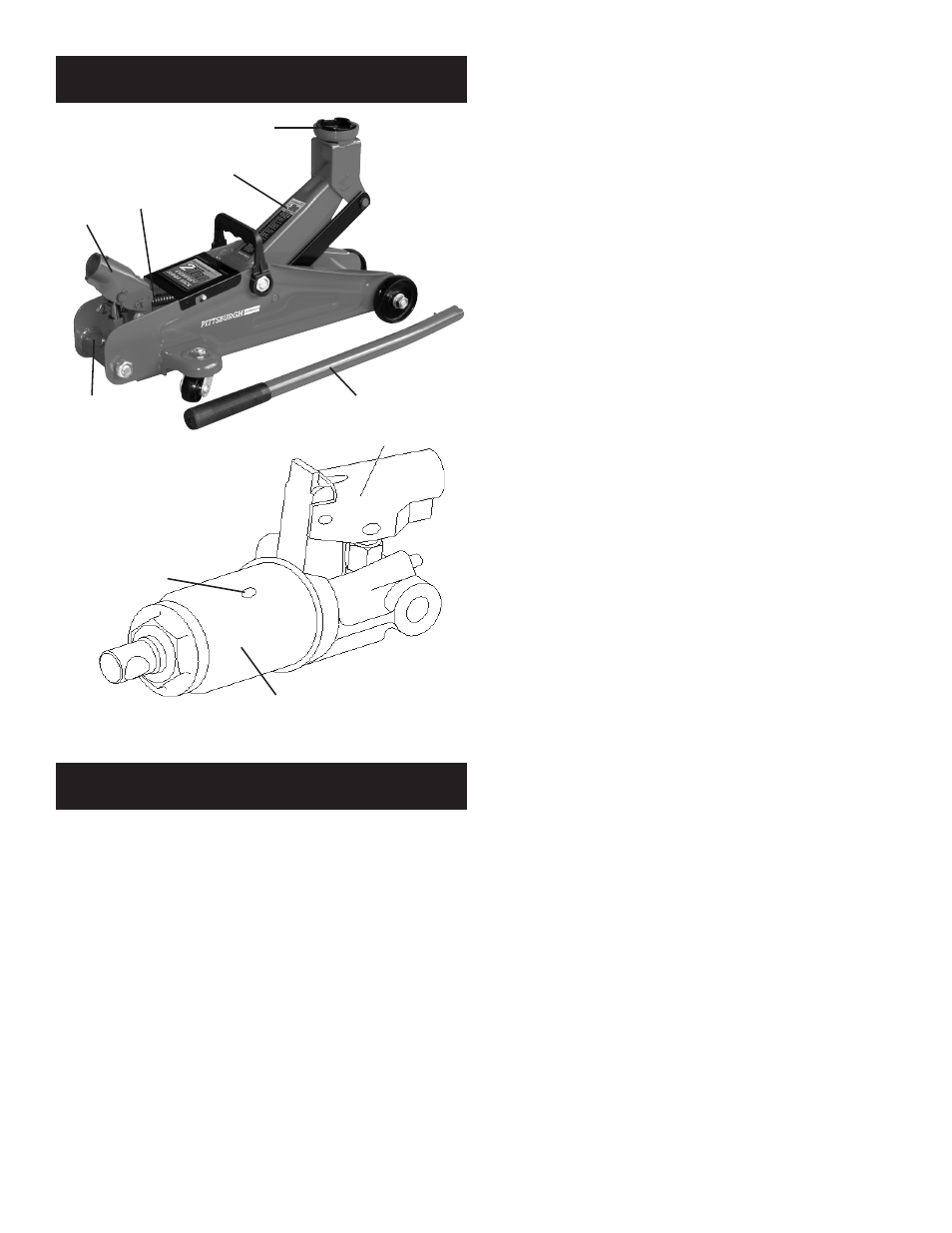

Jack Components

Saddle

Lifting Arm

Handle

Socket

Handle

Oil Fill Screw

(Not Shown)

Fig. 1

Oil Fill Screw

Hydraulic Unit

Handle Socket

Fig. 2

Setup and Operation

Attaching the Handle

1. Insert the Handle into the Handle Socket.

2. Turn Handle clockwise until Handle bases

is securely threaded into Socket.

Bleeding

1. Loosen the Oil Fill Screw (Fig. 2).

2. Insert the Handle into the Release Valve.

3. Turn the Handle (Fig. 1) counterclockwise to open valve.

4. Insert the Handle into the Handle Socket. Pump

the Handle (Fig. 1) up and down quickly for several

times to purge the air from the system.

5. Tighten the Oil Fill Screw (Fig. 2).

Adding Oil

1. Remove the Oil Fill Screw (Fig. 2).

2. Add qualified hydraulic oil of high grade into

the Fill Screw (Fig. 2) opening slowly until

the oil reaches the top of the oil fill hole.

Note: Do not touch Handle when adding the hydraulic oil.

3. Replace the Fill Screw (Fig. 2).

Lifting

1. Park vehicle on a flat, level, solid, surface safely

away from oncoming traffic. Turn off the vehicle’s

engine. Place the vehicle’s transmission in “PARK”

(if automatic) or in its lowest gear (if manual).

Set the vehicle’s emergency brake. Then,

chock the wheels that are not being lifted.

2. Turn the Release Screw (located under the

Handle Socket) counterclockwise to lower the

Jack. Once the Jack is fully lowered, turn the

Release Screw firmly clockwise to close it.

3. Carefully position Saddle of Jack (Fig. 1) under the

vehicle manufacturer’s recommended lifting point. If

equipped, the Elevating Screw can be used to alter the

height of the jack’s saddle; it is adjusted by turning the

saddle clockwise or counterclockwise. (See vehicle

manufacturer’s owner’s manual for location of frame

lifting point when lifting only one wheel, and frame lifting

points when lifting entire front or rear end of vehicle.)

4. Pump the Handle until the top of the Jack’s Saddle

has nearly reached the vehicle lifting point.

Note: The Jack should be positioned at 90° to the

vehicle’s lifting point to ensure the Jack’s Saddle

and vehicle lifting point are in alignment. If not,

reposition the Jack before lifting the vehicle.

5. To lift the vehicle, pump the Handle of the Jack.

Use smooth, full strokes for best results.

6. Once the vehicle is raised, slide a jack stand of

appropriate capacity (not included) under the

proper lifting point referred to in the vehicle owner’s

manual. Always use two jack stands, position them

at the same point on each side of the vehicle.

WARNING! The rated capacity of jack stands is per pair,

not the individual capacities combined unless specifically

noted on the product by the jack stand manufacturer. Do

not exceed rated jack stand capacity. Ensure that the

vehicle support points are fully captured between the outer

lugs of both jack stands. Use a matched pair of jack stands

per vehicle to support one end only. Use 1 pair per vehicle

only. Failure to do so may result in sudden loss of load,

which may cause personal injury and/or property damage.

Release Valve