Start-up, Maintenance, Condensate drain traps – Heatcraft Refrigeration Products 4346B001 User Manual

Page 4: Internally isolated units

4

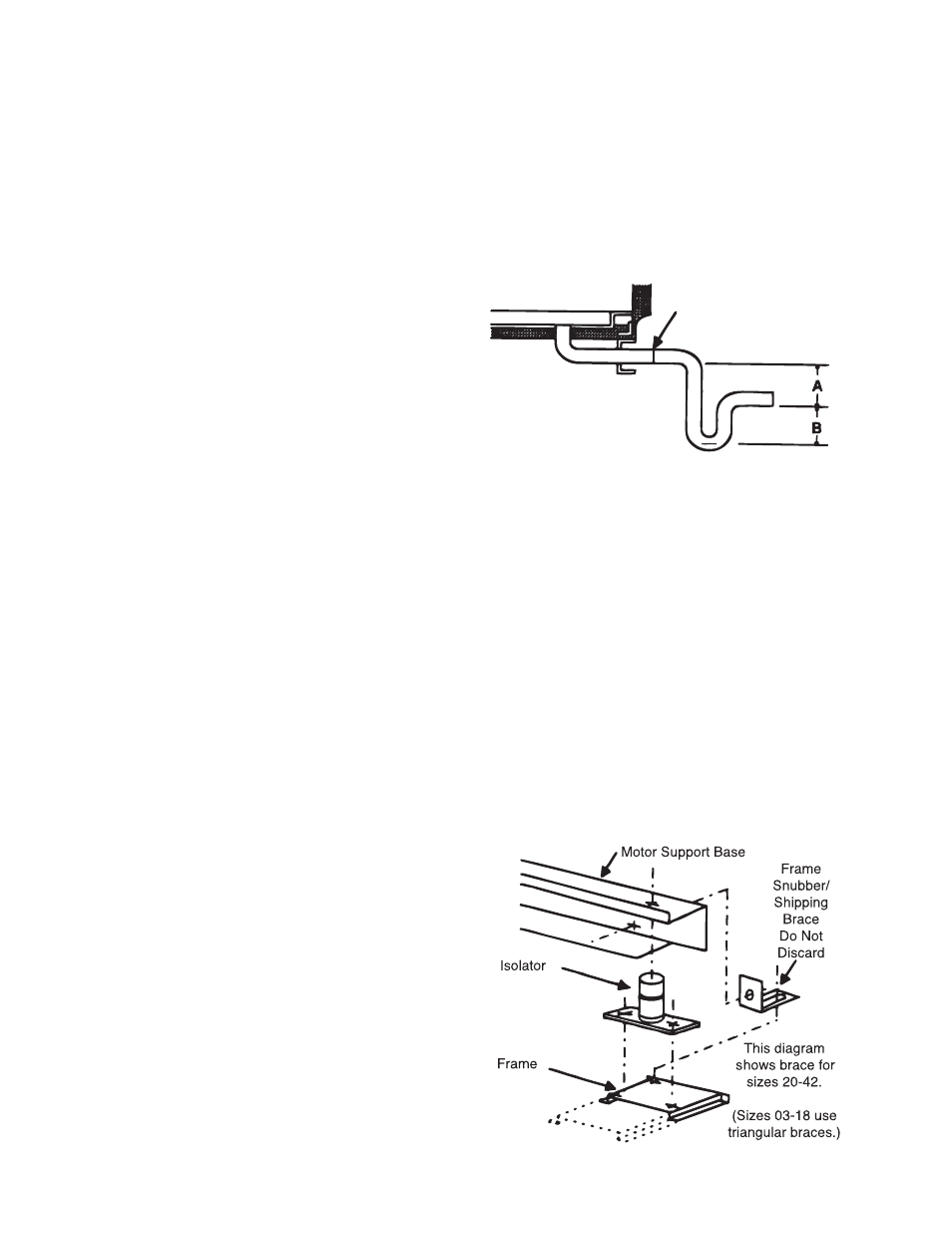

Condensate Drain Trap

(Air Seal)

1 1/4” Pipe Drain

Start-Up

Make sure all bolts and screws are tight.

Remove tagged shipping tie-down bolts and spacers

from the fan and motor assembly before start-up.

(Internally isolated units only.)

Check the sheaves to see if they are alignment and

make suer the set screws are tight. Make sure that

the dimension across the top is equal on all grooves,

otherwise excessive belt wear will result.

Check for proper rotation of the blower pulley. Three

phase motor rotation can be reversed by exchanging

two of the three leads at the motor starter. The rotation

of single phase motors can be reversed by exchanging

leads inside the motor junction box. (See motor wiring

diagram.)

Check the amperage draw of the motor. This should not

exceed the nameplate amps shown on the motor serial

plate.

After approximately two weeks of operation, the belts

will have nearly acquired their permanent stretch. After

this interval, the belt tension should be checked again

and proper adjustment made.

Maintenance

The belt tension should be checked at three month

intervals.

The fan shaft bearings on Sizes 03, 06, 08, 10, and

12 with low pressure forward curved fans have lifetime

lubricated bearings. All other units have ball bearings

which can be relubricated. These bearings mounted

inside the fan section have extended lubrication lines

which are mounted on the outside of the fan panels.

The suggested greasing intervals indicated in a sticker

attached to the unit.

It is recommended that bearings be lubricated with a

high quality lithium grease at intervals indicated on

sticker attached to the unit.

Instructions are included on the motor nameplate for

lubricating the motor bearings.

The filter should be periodically inspected and replaced

or cleaned when necessary. Dirt filters reduce the sir

flow which reduces the capacity of the system.

Do not operate system without filters.

Condensate Drain Traps

The condensate drain trap piping must be properly

designed to insure the removal of condensate. Incorrect

trapping can hold water in pan causing overflow. On

blow-thru units, particular, system air can escape down

the drain with incorrect trapping.

(a) On draw-thru units (A) shall be equal to or

greater the coils section’s negative pressure at

operating conditions.

(b) On blow-thru units (A) can be as small as 1” but

(B) must equal or exceed the total static pressure

in the coil section.

Internally Isolated Units

Sizes 03-41 which have optional internal spring isolation

have four hold-down shipping braces. Remove the 1/2”

bolt between each shipping brace and the motor base,

then loosen the bolt to the frame and slide the brace to

the end of the slot so that the brace is 5/8” from motor

support base. Re-tighten the bolt so that the shipping

brace acts as a snubber on fan start up.