Henkel, inc, Flux and electrode stabilizing ovens, Manufacturer o keen ovens f quality since 1923 – Henkel K-15R User Manual

Page 7

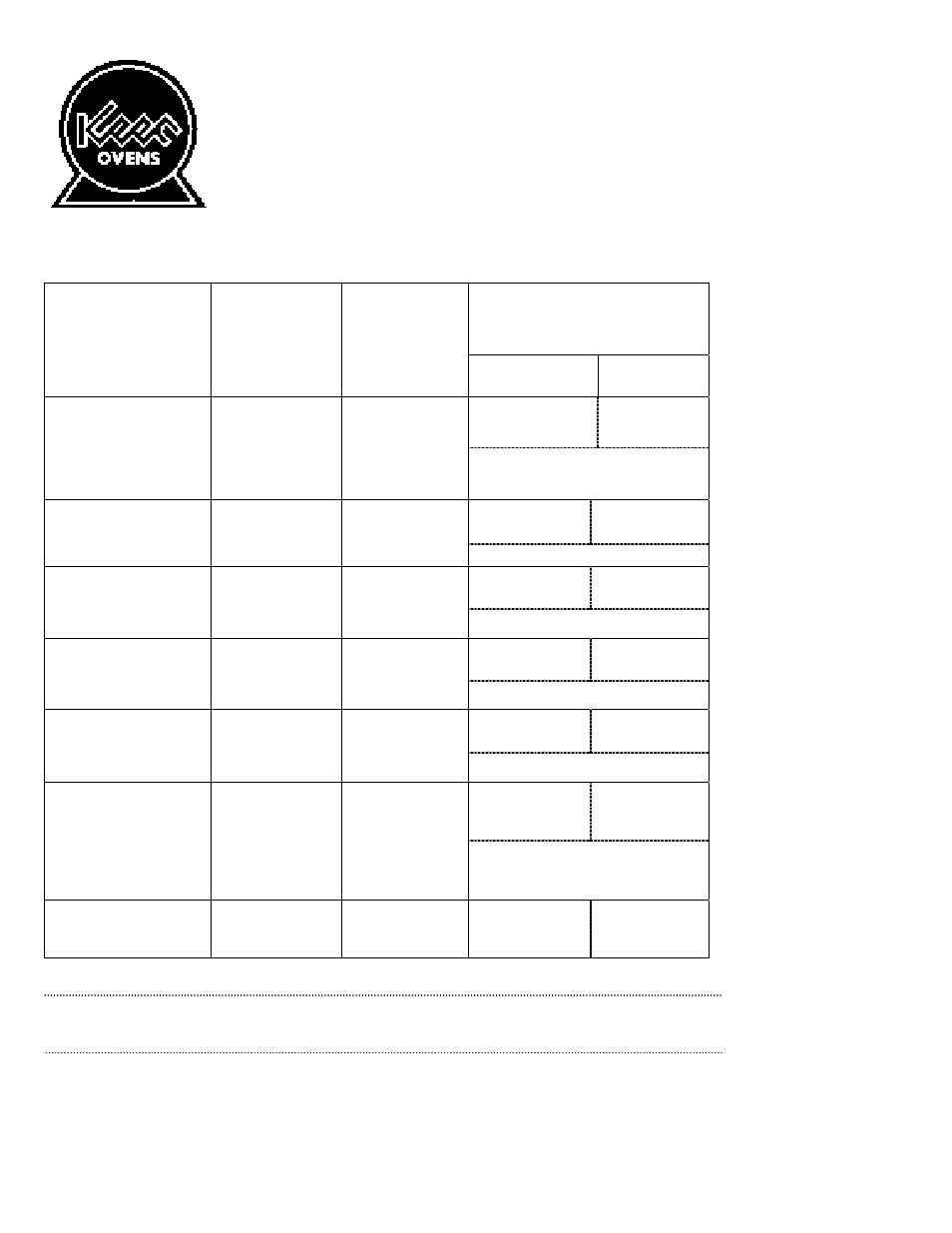

After Exposure to Moisture a

Sufficient Time to affect Weld

Quality

Type (AWS)

Air Conditioned

Storage

Before Opening

Dry Rod

Oven Holding

After Opening

Recondition

Step 1

Rebake

Step 2

180

°F ± 25°

two hours

240

°F ± 25°

one hour

Standard

EXX10

EXX11

EXX12

EXX13

EXX20

EXX30

80

°F ± 20°

60%

± 10% RH

140

°F ± 30°

Three hour total

180

°F ± 25°

two hours

325

°F ± 25°

one hour

Iron Powder

EXX14

EXX24

EXX27

90

°F ± 20°

50% RH max

140

°F ± 30°

Three hour total

180

°F ± 25°

two hours

700

°F ± 100°

one-half hour

Iron Powder-

Low Hydrogen

EXX18

EXX28

90

°F ± 20°

50% RH max

400

°F ± 50°

Two & one-half hour total

180

°F ± 25°

two hours

600

°F ± 100°

one-half hour

Low Hydrogen

EXX15

EXX16

90

°F ± 20°

50% RH max

400

°F ± 50°

Two & one-half hour total

180

°F ± 25°

two hours

700

°F ± 100°

one-half hour

Low-Hydroge

n

High Tensile

EXXX15

EXXX16

90

°F ± 20°

50% RH max

400

°F ± 50°

Two & one-half hour total

180

°F ± 25°

one hour

350

°F ± 50°

one hour

Stainless

Inconel

Monel

Nickel

Brasses

Bronzes

Hard Surfacing

Special Alloys

90

°F ± 20°

50% RH max

225

°F ± 50°

Two hour total

Granulated or

Agglomerated

Flux

90

°F ± 20°

50% RH max

240

° F ± 50°

Not required

700

°F ± 100°∅

two hours

CONTACT YOUR ELECTRODE MANUFACTURER FOR SPECIFIC INFORMATION INVOLVING

CRITICAL OPERATIONS.

Electrode coating should not be exposed to the rebaking temperature without first having been

reconditioned at a lower temperature. Failure to observe this rule will result in breakdown of

electrode coatings.

After rebake, lower temperature to holding level until reissue.

Note: In the HTS Stainless

electrode groups, and 15 &

16 type coatings, there can

e a greater difference in the

maximum temperature

requirements for rebaking

than those shown. This can

be handled by special

request to the particular

manufacturer involved.

b

IMPORTANT:

This table is offered as a

guide to proper storage

and oven holding

temperatures for the

most common

electrodes in use today.

In addition,

recondition/rebake

procedures for electrode

coatings that have been

exposed to moisture for

a sufficient period of

time to affect the weld

quality are included.

Good judgment and the

manufacturer’s

recommendations

should be your guide.

Flux and Electrode Stabilizing Ovens

HENKEL, INC.

Manufacturer o KEEN Ovens

f

Quality Since 1923.

Phone (985) 345-2171

Fax (985) 345-5653

PO Box 1322

Hammond, Louisiana

70401