Hitachi INVERTER J300 User Manual

Page 6

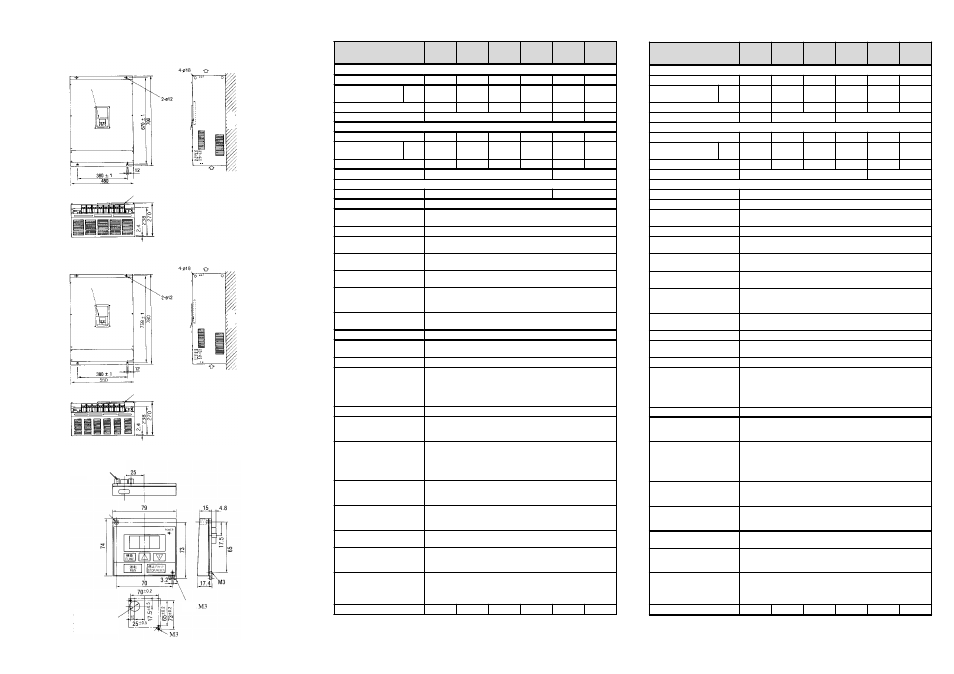

External dimensions and terminal positions part 2/2 (part 1/2 on previous page)

J300-

750 HFE4

900 HFE4

Air

Control

terminals

Main terminals

Wa

ll

Digital operator

Air

J300-1100 HFE4

Air

Control

terminals

Main terminals

Wa

ll

Digital operator

Air

Digital operator

OPE-J

Connector for

extension cable

Cutout for

connector

25mm

e.g.

T ec hn ic a l S pe ci f ic a t io ns

Inverter J 3 0 0

-

370

HFE4

450

HFE4

550

HFE4

750

HFE4

900

HFE4

1100

HFE4

Loads having constant torque

Maximum motor size in kW

37

45

55

75

90

110

Maximum motor

capacity in kVA

400V

52

62

76

103

122

150

Rated output current in A

75

90

110

149

176

217

Carrier frequency in kHz

2 – 10

2 – 6

2 – 3

Loads having quadratically rising torque

Maximum motor size in kW

45

55

75

90

110

132

Maximum motor

capacity in kVA

400V

61

75

101

122

150

180

Rated output current in A

88

108

146

176

217

260

Carrier frequency in kHz

2 – 4

2

General technical specifications

Protective structure

IP00

Rated input voltage

Three phase 380 ~ 460V +/-10%, 50/60Hz +/-5%

Rated output voltage

Three phase 0 .. 380 ~ 460VAC

(Corresponds to input voltage)

Output frequency range

0,1 ~ 400Hz

Operating principle

Sensorless Vector Control (SLV), PWM sine coded.

Power amplifier: IGBT/IPM

Overload current capacity

150% during 60s (constant torque)

115% during 30s (quadratically rising torque)

Frequency accuracy

(at 25°C +/-10°C)

Digital command: +/-0.01% of the maximum frequency

Analog command: +/-0.1% of the maximum frequency

V/F characteristics

V/F curves with constant and reduced torque;

vector control without feedback;

vector control with feedback (optional)

Autotuning

Automatic adaption to motor characteristics to make

best use of the motor driven

AVR function

Automatic Voltage Regulation usable

Acceleration/Deceleration

2 times settable between 0.01 and 3000s (using digital remote

control); linear, S-curve, U-curve

Starting torque

150% at 1Hz (constant torque)

Braking resistor

Models J300-055HFE4 and J300-075HFE4 have a built-in braking

resistor. Braking torque approx. 50% to 60% of the rated torque

using the built-in braking resistor (the rest of the J300- models have

a braking torque of approx. 10% to 15% of the rated torque using

braking with feedback to capacitor).

DC braking

Variable operating frequency, time, and braking force.

Frequency command

Digital command using the built-in digital operator keys.

Analog 0–5V and 0–10V (input impedance 30kOhm) and

4–20mA (input impedance 250Ohm); optional digital input

Intelligent digital inputs

8 inputs configurable as: Forward run, Reverse run, Free run mode,

Reset, Jog, 7 multistage speed settings, Ext. DC braking, 2. Setting,

2. Stage accel/decel, External alarm, USP function, Software lock,

frequency command from analog input O or OI, Motor poten-

tiometer, Motor free run, Factory setting, etc.

Outputs

Analog output current, output frequency, and torque.

Transistor output with signals for frequency arrival, motor

running, torque alarm; Alarm output

Other functions

Optimized acceleration and deceleration times using fuzzy logic,

engergy saving mode, electronic thermal, jump frequency,

upper/lower limits, PID control, etc.

Protective functions

Overcurrent, overvoltage, undervoltage, overload, excessive

temperature, ground fault, braking resistor overload, etc.

Directives and standards

CE-EMC directive in conjunction with optional radio noise

filter and installation according to installation guidelines;

CE low voltage directive

Operating environment

Ambient temperature: -10~50°C with constant torque

and -10~40°C with quadratically rising torque.

Humidity: 20-90% RH (non condensing); Installation altitude:

1000m or less

Overall weight (approx.)

36

46

46

70

70

80

T ec hn ic a l S pe ci f ic a t io n s

Inverter J 3 0 0

-

055

HFE4

075

HFE4

110

HFE4

150

HFE4

220

HFE4

300

HFE4

Loads having constant torque

Maximum motor size in kW

5.5

7.5

11

15

22

30

Maximum motor

capacity in kVA

400V

9.0

11

16

22

33

40

Rated output current in A

13

16

23

32

48

58

Carrier frequency in kHz

2 – 16

2 – 12

2 – 10

Loads having quadratically rising torque

Maximum motor size in kW

7.5

11

15

22

30

37

Maximum motor

capacity in kVA

400V

11

16

22

30

41

51

Rated output current in A

16

23

32

44

59

74

Carrier frequency in kHz

2 – 8

2 – 4

General technical specifications

Protective structure

IP20

IP00

Rated input voltage

Three phase 380 ~ 460V +/-10%, 50/60Hz +/-5%

Rated output voltage

Three phase 0 .. 380 ~ 460VAC

(Corresponds to input voltage)

Output frequency range

0,1 ~ 400Hz

Operating principle

Sensorless Vector Control (SLV), PWM sine coded.

Power amplifier: IGBT/IPM

Overload current capacity

150% during 60s (constant torque)

115% during 30s (quadratically rising torque)

Frequency accuracy

(at 25°C +/-10°C)

Digital command: +/-0.01% of the maximum frequency

Analog command: +/-0.1% of the maximum frequency

V/F characteristics

V/F curves with constant and reduced torque;

vector control without feedback;

vector control with feedback (optional)

Autotuning

Automatic adaption to motor characteristics to make

best use of the motor driven

AVR function

Automatic Voltage Regulation usable

Acceleration/Deceleration

2 times settable between 0.01 and 3000s (using digital remote

control); linear, S-curve, U-curve

Starting torque

150% at 1Hz (constant torque)

Braking resistor

Models J300-055HFE4 and J300-075HFE4 have a built-in braking

resistor. Braking torque approx. 50% to 60% of the rated torque

using the built-in braking resistor (the rest of the J300- models have

a braking torque of approx. 10% to 15% of the rated torque using

braking with feedback to capacitor).

DC braking

Variable operating frequency, time, and braking force.

Frequency command

Digital command using the built-in digital operator keys.

Analog 0–5V and 0–10V (input impedance 30kOhm) and

4–20mA (input impedance 250Ohm); optional digital input

Intelligent digital inputs

8 inputs configurable as: Forward run, Reverse run, Free run mode,

Reset, Jog, 7 multistage speed settings, Ext. DC braking, 2. Setting,

2. Stage accel/decel, External alarm, USP function, Software lock,

frequency command from analog input O or OI, Motor poten-

tiometer, Motor free run, Factory setting, etc.

Outputs

Analog output current, output frequency, and torque.

Transistor output with signals for frequency arrival, motor

running, torque alarm; Alarm output

Other functions

Optimized acceleration and deceleration times using fuzzy logic,

engergy saving mode, electronic thermal, jump frequency,

upper/lower limits, PID control, etc.

Protective functions

Overcurrent, overvoltage, undervoltage, overload, excessive

temperature, ground fault, braking resistor overload, etc.

Directives and standards

CE-EMC directive in conjunction with optional radio noise

filter and installation according to installation guidelines;

CE low voltage directive

Operating environment

Ambient temperature: -10~50°C with constant torque

and -10~40°C with quadratically rising torque.

Humidity: 20-90% RH (non condensing); Installation altitude:

1000m or less

Overall weight (approx.)

7.5

7.5

13

13

21

36

12

13

14