Superior valve company, Table 25. type f filter, Table 26. type df (for clean-up) – Heatcraft Refrigeration Products H-IM-72A User Manual

Page 30: Alco controls, Table 27. type af filter, Table 28. type afd (for clean-up), Head pressure control, Valve functions

30

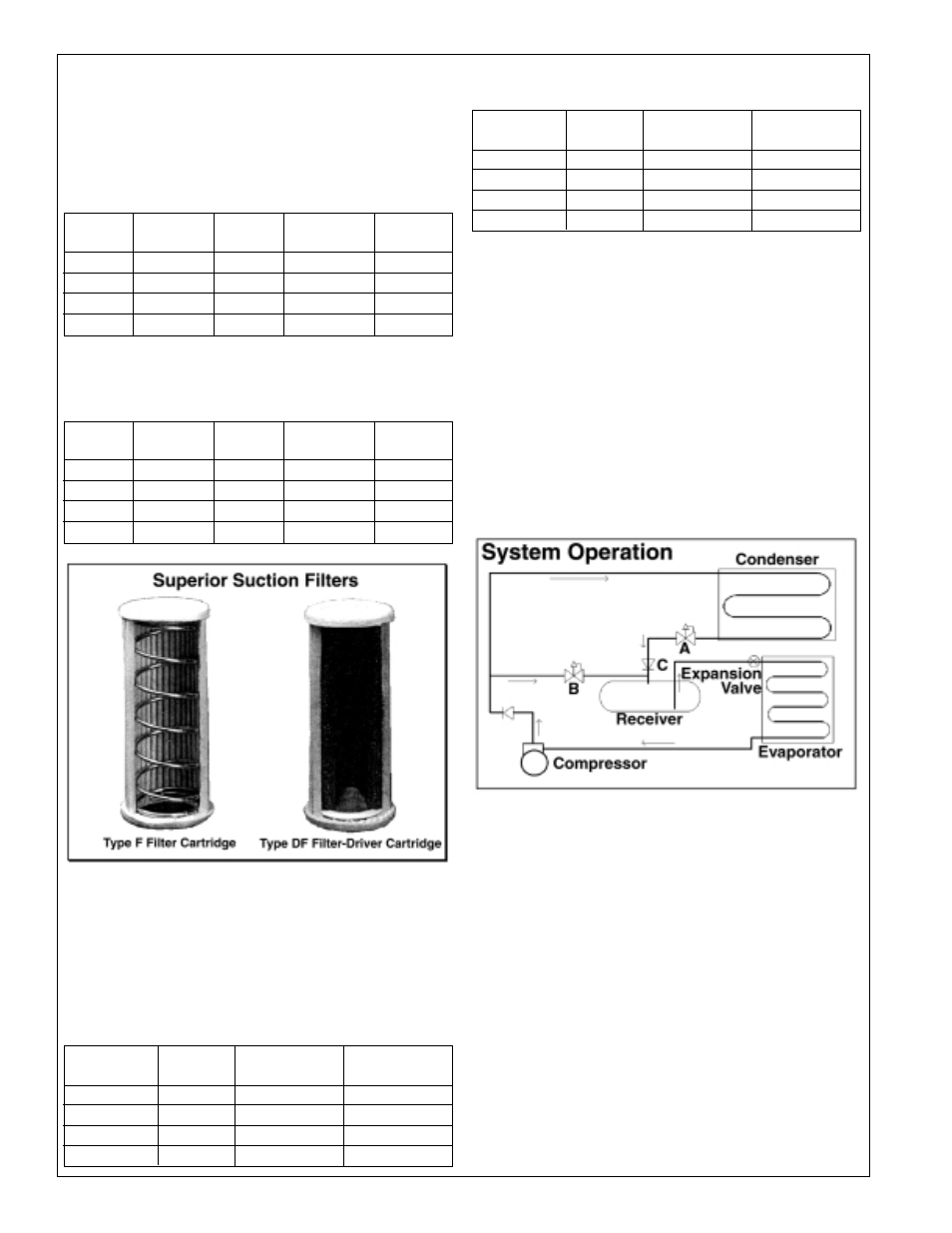

Superior Valve Company

Replaceable Suction Filter

• On many parallel systems, the Superior Valve Co.

suction filter is installed.

Table 25. Type F Filter

Replaceable Cartridges

Shell

Catalog

IBCA

Cartridge

Filter

No.

No.

No.

OD (in)

Area (in

2

)

2CFA

F25A

51071

1 - 23/32

66

3CFA

F35A

51072

2 - 5/8

115

4CFA

F45A

51073

3 - 17/32

189

5CFA

F55A

51074

4 - 1/16

270

Table 26. Type DF (for cleanup)

Replaceable Cartridges

Shell No.

Catalog

IBCA

Cartridge

Filter

No.

No.

No.

OD (in)

Area (in

2

)

2CFA

DF25A

51053

1 - 23/32

66

3CFA

DF35A

51059

2 - 5/8

115

4CFA

DF45A

51060

3 - 17/32

189

5CFA

DF55A

51061

4 - 1/16

270

Alco Controls

Alco Suction Filter

Comparable to the Superior suction filters and

interchangeable cores.

Table

27. Type AF Filter

Replaceable Cartridges -

Shell

Filter

Cartridge

Filter Area

No.

Core

OD (in)

Area (in

2

)

BTAS-2

A2F

1 - 29/32

66

BTAS-3

A3F

2 - 3/4

115

BTAS-4

A4F

3 - 3/4

189

BTAS-5

A5F

4 - 5/16

270

Table

28. Type AFD (for cleanup)

Replaceable Cartridges -

Shell

Filter

Cartridge

Filter Area

No.

Core

OD (in)

Area (in

2

)

BTAS-2

A2F-D

1 - 29/32

66

BTAS-3

A2F-D

2 - 3/4

115

BTAS-4

A2F-D

3 - 3/4

189

BTAS-5

A2F-D

4 - 5/16

270

Head Pressure Control

In a system with variable pressure control the receiver

pressure is maintained at the desired pressure by supplying

discharge gas to it through an adjustable outlet regulator.

Further power savings may be realized by directing only the

hot gas to the top of the receiver to minimize the mixing of

cold liquid and hot gas. As a result subcooled liquid is fed to

the evaporators resulting in increased refrigeration effect and

efficiency. Also, the amount of hot gas, that would otherwise

condense to wary liquid, is reduced and a lower cost, smaller

regulator can be used. In general, only one third of bypass is

needed compared to mixing the gas and liquid entering the

receiver.

Valve Functions

Referring to the Figure above, Valve A is an Inlet Pressure

Regulator in the liquid drain line from the condenser, and

senses the condenser pressure. The regulator closes as the

condenser pressure drops below the set point, thus back-

flooding the condenser and reducing the inside surface area

available for condensing.

Valve B is and Outlet Pressure Regulator in the bypass line

from compressor discharge to the condenser liquid drain line.

This valve senses the receiver pressure and opens when this

pressure drops below the set point, thus maintaining the

receiver pressure.

Valve C is an In-line Check Valve in the liquid drain line to

prevent higher pressure from backing up into the condenser

during low ambient conditions when the compressor is idle.