Components, Mounting, Safety opera tion inspection inst alla tion – Harbor Freight Tools 41005 User Manual

Page 4

Page 4

For technical questions, please call 1-800-444-3353.

Item 41005/67500

Installation Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

Note: For additional information regarding the parts listed in the following pages,

refer to Parts List and Assembly Diagram on page 6.

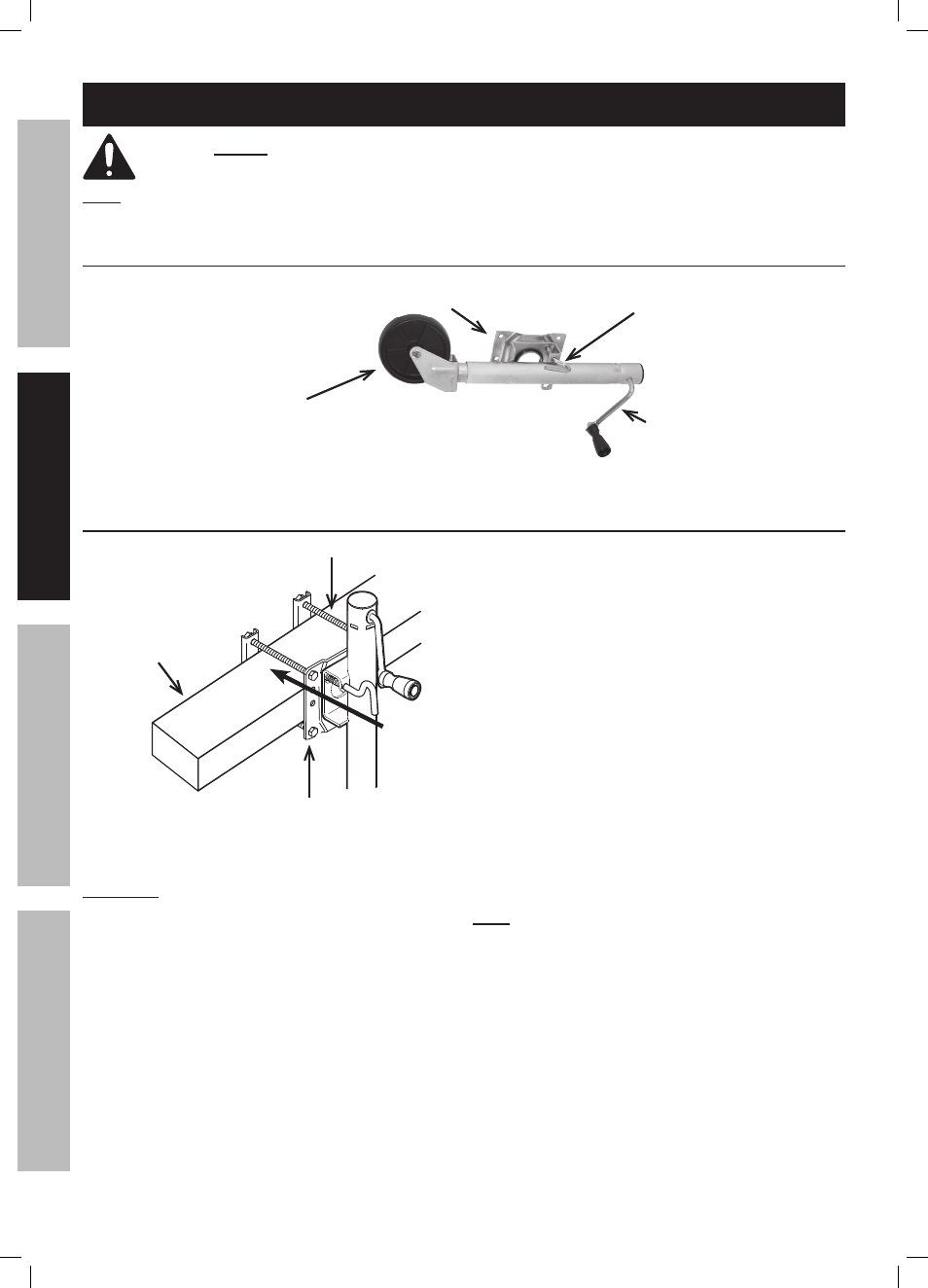

Components

Figure A

Crank

Swivel Handle

(May be single hook

type or “D” type handle)

Rotating Plate

Wheel

(One wheel for 1000 lb. Jack and

two wheels for 1500 lb. Jack)

Mounting

Square or Rectangular

Trailer Tongue

Bolt

Mounting

Plate

Figure B

Insert Bolts

in this

direction

WARNING: The trailer tongue must be square

or rectangular in profile for this Jack to mount

properly. A cylindrical tongue will allow the Jack to

rotate off to the side and the trailer may suddenly

fall, potentially causing serious personal injury or

property damage. Do not drill holes or otherwise

damage the trailer tongue when installing this

Jack, as failure of the trailer tongue may result.

Install the Jack with the Trailer mounted

on the towing vehicle hitch.

1. Measure the trailer tongue for the best location

to mount the Jack. Consider the following:

a. The Jack will fit a 3″-5″ high tongue. Position

the Mounting Plate horizontally for a 3″ to 4″

tall location or vertically for a 4″ to 5″ location.

b. Allow room on both sides of the mounting location

for the Jack to swing up to its horizontal position.

c. Check that the Jack will not interfere with

the Vehicle or trailer when turning or passing

over speed bumps, boat ramps, etc.

d. d. To prevent overloading the jack, attach

it as near to the coupler as is practical.

2. The Mounting Hardware includes four mounting

bolts, washers, spring washers, and nuts to attach

the Jack. Position the Rotating Plates so that the

mounting bolts are as close as possible to the top

and bottom edge of the trailer tongue. Use the

configuration that best fits the trailer tongue.

Note: Insert the Bolts from the Rotating

Plate side, so that the Nuts and Bolt ends do

not interfere when rotating the Jack.

3. Test the operation of the Trailer Jack. Rotate

the Crank clockwise to raise the Trailer Jack

and counterclockwise to lower it. Pull the Swivel

Handle and rotate the Trailer Jack so it’s in line

with the trailer tongue, then rotate it down so the

wheels are on the ground. Make sure that the

Jack is able to lock into both of its positions.

4. Make any adjustments to the Trailer Jack

location as necessary, then tighten the

Mounting Hardware firmly to 15-20 ft. lb. Use

a torque wrench to confirm tightness.

SAFETY

OPERA

TION

INSPECTION

INST

ALLA

TION