Cleaning, maintenance, and lubrication, Troubleshooting – Harbor Freight Tools Drill Master 3733 User Manual

Page 17

Page 17

SKU 3733

For technical questions, please call 1-800-444-3353.

cleaning, Maintenance, and

Lubrication

BEFORE EAcH uSE,

1.

inspect the

general condition of the tool. Check

for loose screws, misalignment or

binding of moving parts, cracked or

broken parts, damaged electrical

wiring, loose or worn out blade, and

any other condition that may affect its

safe operation.

AFTER uSE,

2.

clean external surfaces

of the tool with clean cloth. Drain wa-

ter from the water tray and wash out

any residue from the recessed pump

sump area.

Tool service must be performed

3.

only by qualified repair personnel.

Service or maintenance performed by

unqualified personnel could result in

a risk of injury.

When servicing a tool, use only

4.

identical replacement parts. Fol-

low instructions in the “Inspec-

tion, Maintenance, And Cleaning”

section of this manual. Use of

unauthorized parts or failure to follow

maintenance instructions may create

a risk of electric shock or injury.

5.

WARnIng! If the supply cord of

this power tool is damaged, it must

be replaced only by a qualified

service technician.

To clean:

6.

Wipe with a damp cloth,

vacuum or use compressed air. Do

not use solvents.

When storing:

7.

Store Tile Saw in a

safe, clean, dry, location out of reach

of children.

cAuTIOn!

8.

All maintenance, service,

or repairs not listed in this manual are

only to be attempted by a qualified

service technician.

Troubleshooting

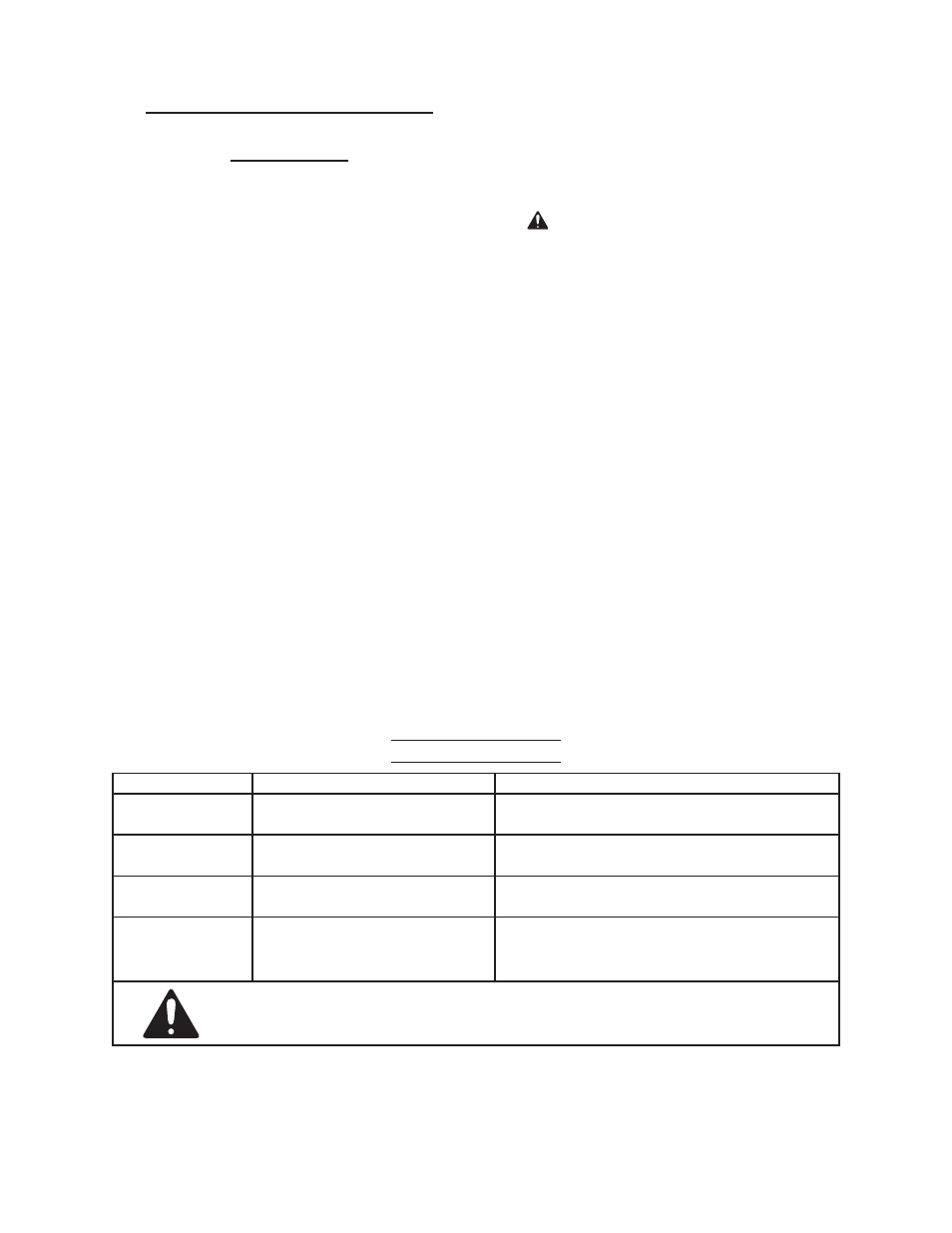

problem

possible causes

Likely Solutions

Tool will not start

No power at outlet.

1.

Cord not connected.

2.

Check power at outlet.

1.

Check that cord is plugged in.

2.

Blade spins slowly

Arbor shaft binding

1.

Motor brushes worn

2.

Check shaft for free spinning

1.

Replace brushes

2.

Excessive vibration

Bent or off-balance blade

1.

Bent Arbor Shaft

2.

Replace blade with new one

1.

Check shaft for run-out

2.

Running hot;

excess smoke

Water flow problem.

1.

Not enough water

2.

Running with hot/warm water

3.

Check connection

1.

Add proper amount of water

2.

Always run with cold water

3.

Follow all safety precautions whenever diagnosing or servicing the

tool. disconnect power supply before service.