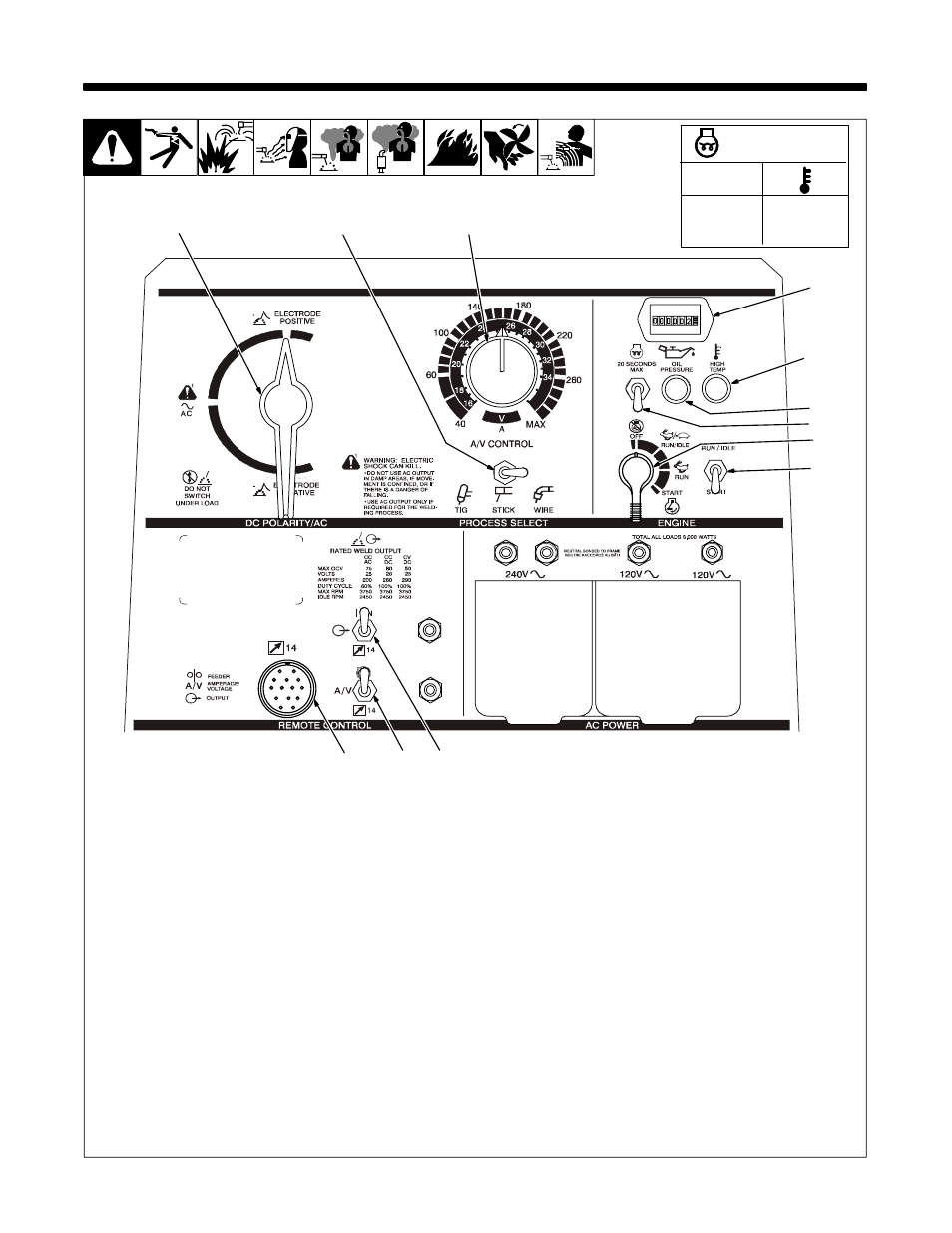

1. front panel controls – Hobart Welding Products ARCSTAR OM-487 User Manual

Page 22

OM-487 Page 18

SECTION 5 – OPERATING WELDING GENERATOR

5-1.

Front Panel Controls

Ref. ST-187 602-A

1

DC Polarity/AC Switch

Y

Do not switch under load.

Use switch to select AC weld output or polarity

of DC weld output.

2

Process Select Switch

Y

Do not switch under load.

Use switch to select output for weld process.

3

A/V Control

Use control to select weld voltage or

amperage. Control may be adjusted while

welding.

4

Engine Hour Meter

5

High Engine Temperature Light

Light goes on and engine stops if engine tem-

perature is too high.

Y

Do not run engine until trouble is fixed.

6

Low Oil Pressure Light

Light goes on and engine stops if engine oil

pressure is too low.

Y

Do not run engine until trouble is fixed.

7

Glow Plug Switch

If necessary, push switch up before start-up

(see table above).

Y

Do not use glow plugs longer than 20

seconds.

8

Engine Control Switch

Use switch to start engine, select speed, and

stop engine. In Run/Idle position, engine runs

at idle speed at no load, and weld/power

speed under load. In Run position, engine

runs at weld/power speed.

.

Place switch in Run position to operate

most GMAW equipment.

9

Idle Lock Switch

Use switch to lock engine in idle speed during

start-up. In Start position and Engine Control

switch in Run or Run/Idle, engine is locked in

idle speed. In Run/Idle position and Engine

Control switch in Run/Idle, engine runs at idle

speed at no load and weld/power speed under

load.

To start: move idle lock switch and engine

control switch to Start. Release engine control

switch when engine starts.

.

If the engine does not start, let the engine

come to a complete stop before attempt-

ing restart.

To Stop: turn Engine Control switch to Off

position.

.

Close fuel valve to stop engine if Engine

Control switch does not work (see

Section 4-3).

10 Output (Contactor) Switch

Use switch to control remote contactor if con-

nected to remote 14 receptacle RC1 (see

Section 5-2). Place switch in Remote 14 posi-

tion if using remote contactor.

Y

Weld output terminals are energized

when Output (Contactor) switch is in

On position and engine is running.

11 Remote Amperage/Voltage Switch

Use switch to select front panel or remote am-

perage/voltage control (see Section 5-2).

12 Remote 14 Receptacle RC3

Use receptacle to connect remote control (see

Sections 4-8 and 5-2).

t

0 s

10 s

20 s

70

°

F (21

°

C)

32

°

F (0

°

C)

–4

°

F (–20

°

C)

Glow Plug Time

1

2

3

4

5

6

7

8

9

11

10

12