Harbor Freight Tools CENTRAL PNEUMATIC 90590 User Manual

Page 5

SKU 90590

PAGE 5

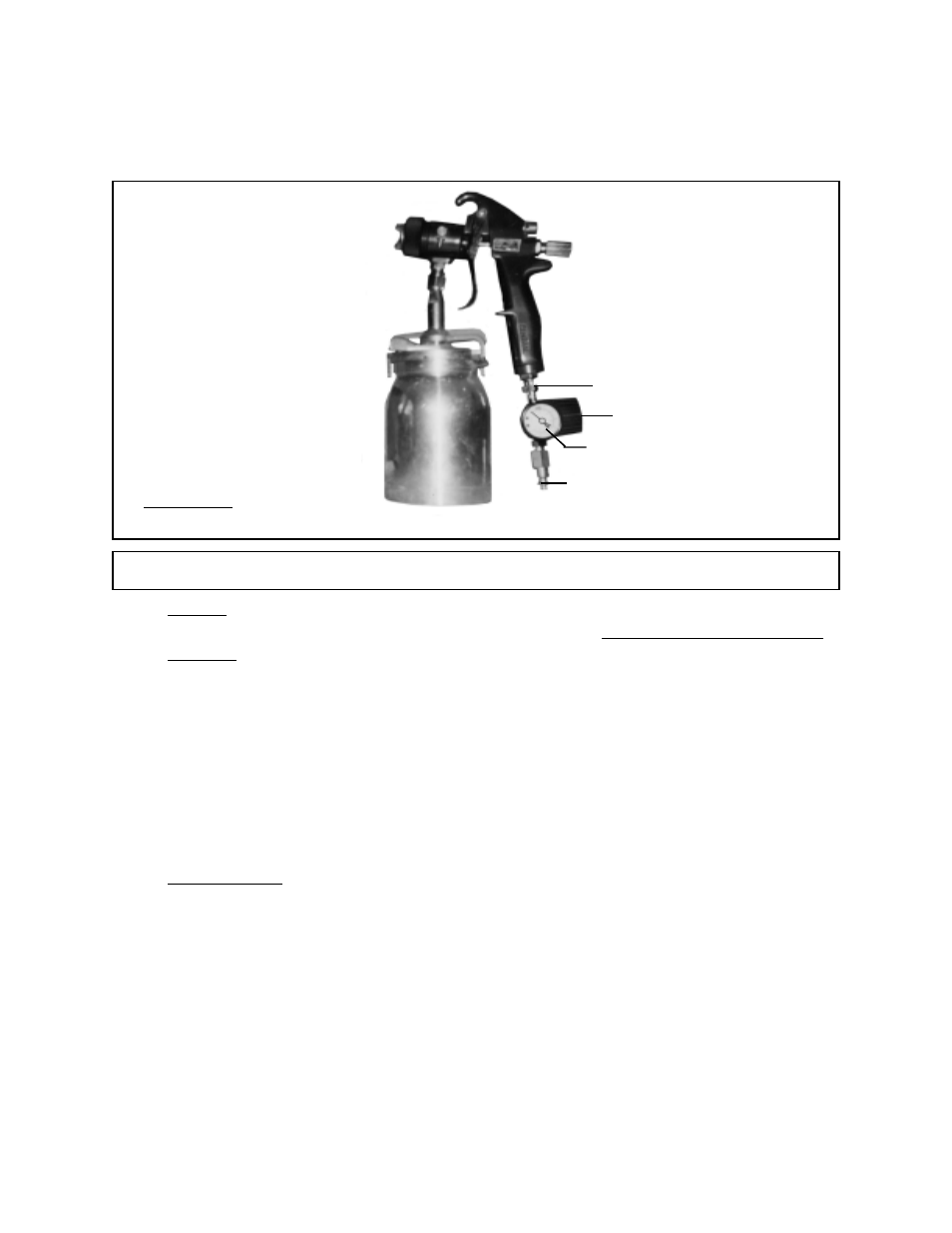

tighten the Air Diaphragm Regulator into the air intake of the spray gun.

(See Figure A.)

CONNECT AIR SUPPLY HOSE

TO COUPLER

(not included)

ADAPTER (#13)

ADJUSTING KNOB (#1)

PRESSURE GAUGE (#14)

FIGURE A

OPERATING INSTRUCTIONS

1.

NOTE: Before starting, make sure to refer to both the

spray gun and paint

manufacturers’ instruction manuals

to determine the proper level of air pressure

required for each specific painting job that is to be performed.

2.

To use the Air Regulator, turn its Adjusting Knob

counterclockwise

all the way.

(See Figure A.) Apply several wraps of sealant tape to the threads of #13

Adapter. Then install a 1/4” NPT or 1/4” NPS coupler plug (not included) on the

Adapter, and wrench tighten.

3.

Connect the air supply hose to the Coupler (not included) of the Air Regulator.

Then, turn on the air compressor. (See Figure A.)

4.

IMPORTANT: The air pressure of the Air Regulator may be adjusted from 0 to

160 PSI. To increase the level of PSI, turn the Adjusting Knob (part #1)

clockwise. To decrease the level of PSI, turn the Adjusting Knob

counterclockwise. (See Figure A.)

5.

Turn the Adjusting Knob (part #1)

clockwise

to raise the air pressure to the de-

sired level as indicated on the Pressure Gauge (part #14). (See Figure A.)

6.

Make sure to spray

waste

material for several seconds prior to starting the actual

job. This allows you to properly adjust the spray gun and, if necessary,

re-adjust

the level of air pressure using the Adjusting Knob (part #1).

SPRAY PAINT GUN

NOT INCLUDED.