Maintenance, Air connections, Operation – Harbor Freight Tools 1118 User Manual

Page 5

SKU 1118

For technical questions, please call 1-800-444-3353

Page 5

1.

Turn on the air compressor and check for leaks. If any are found, turn the Compressor off, drain air from

tank, and fix the leak. WARNING: Do no exceed 160 PSI during use.

2.

With the compressor ON, turn the Adjusting Screw (1C) to set the pressure that you want. Look at the

Pressure Gauge (6B) while you turn the Adjusting Screw. Stop turning the Regulator Handle (1C) when the

Presure Gauge needle points to the desired pressure. See Figure 6.

3.

You must drain the Air Filter/Regulator of water daily. With the unit under pressure, turn the Drain Plug

(14A) to expel any accumulated moisture from the Air Filter. See page 6 parts list A.

Maintenance

1.

Periodically disassemble the Air Filter and remove all dirt and debris. Remove air pressure before cleaning.

2.

Periodically remove the Filter (6A), rinse it out with water and replace. If it is damaged or if it needs to be

replaced you can order a new one by calling 1-800-444-3353 and order SKU 10767 Filter Element.

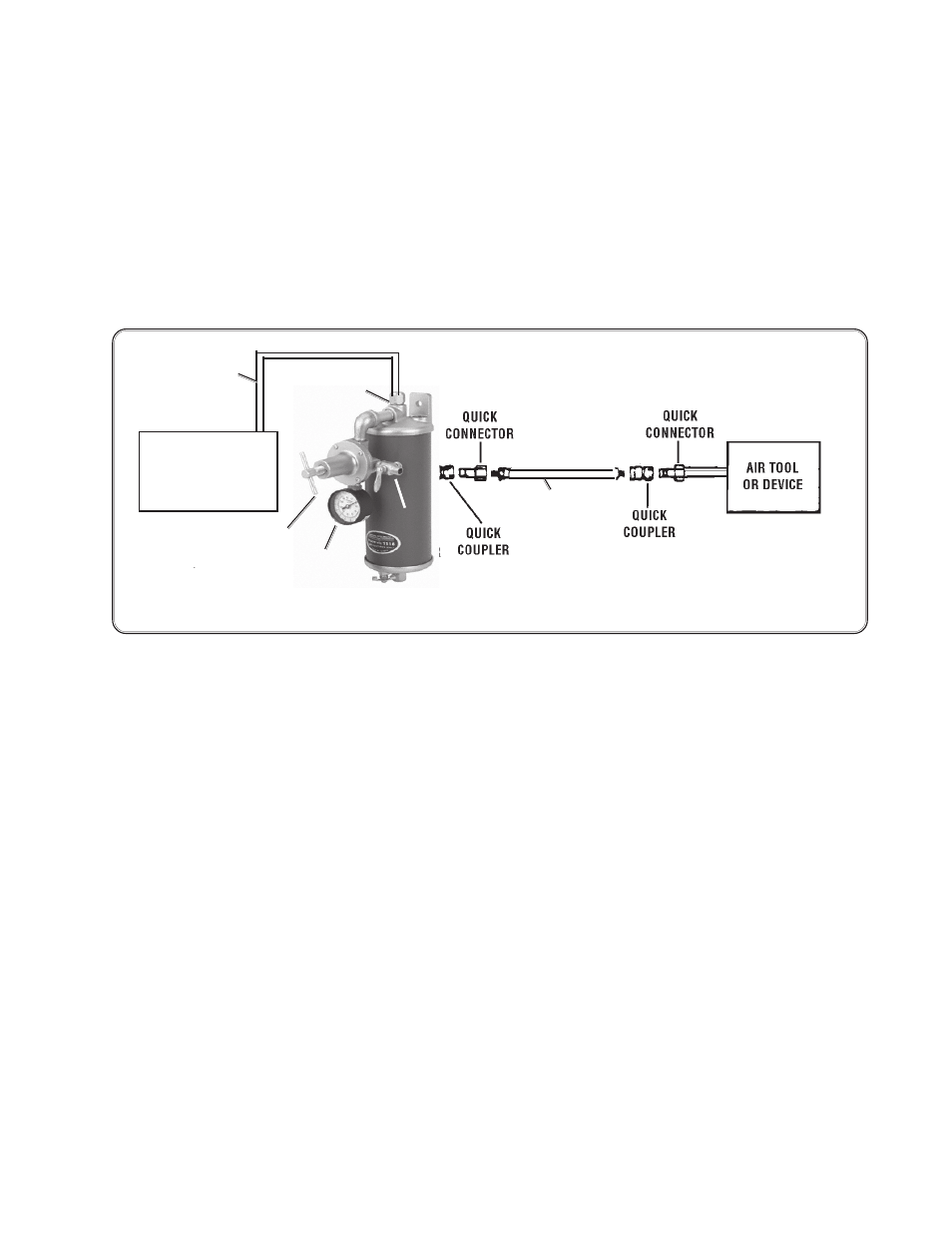

1.

Connect the compressor air output hose (not included) or pipe (not included) to the Air Inlet (7B) and

securely tighten. See Figure 6 below.

2.

Connect the air output hose to the Quick Coupler (not supplied) and screw into the Air Valve (5B) and

securely tighten. See Figure 6 below.

3.

Connect air tool or devise to an output hose. See Figure 6 below.

Air Connections

Figure 6

Caution: To avoid injury, make certain that the air compressor is unplugged from the power source and that all

pressure is released from its tank before connecting the Air Filter/Regulator to it.

AIR COMPRESSOR

Air Inlet (7B)

Air Input Hose

(5B)

Air Output Hose

Operation

Pressure Gauge (6B)

Regulator Handle (1C)