Section 1 specifications – Hach SIGMA 900 User Manual

Page 5

Page 5

8544specs.fm

Specifications

Section 1

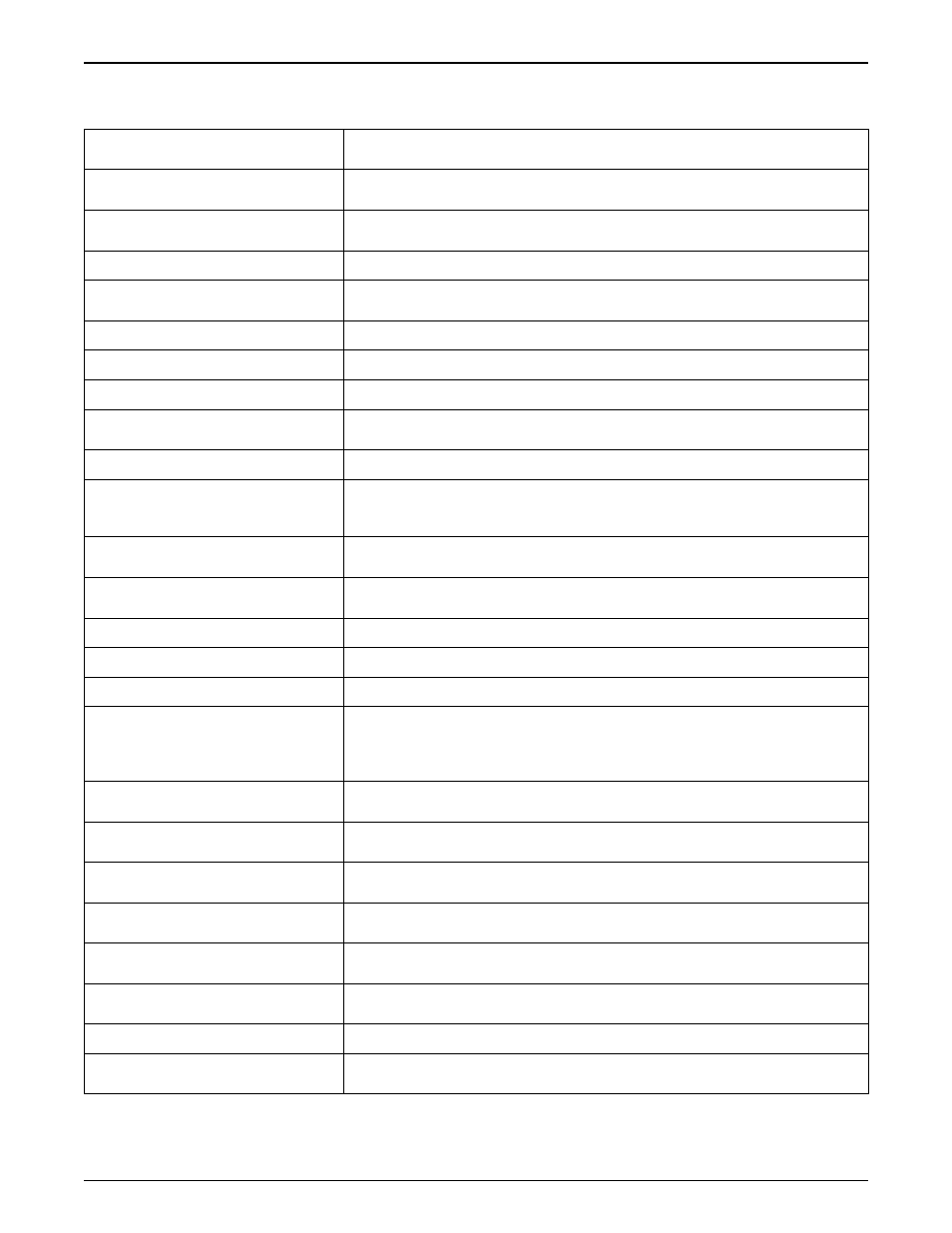

Specifications

Specifications are subject to change without notice.

Controller Dimensions

Height: 34 cm (13.5 in.), Width 28 cm (11 in.), Depth 20.3 cm (8 in.) without wall

bracket, 33 cm (13 in.) deep with wall bracket

Pump/Controller Housing

High impact injection molded ABS: submersible, watertight, dust tight, corrosion

and ice resistant; NEMA 4X, 6

Sample Pump

High speed peristaltic, dual roller, with 9.53 ID x 15.9 mm OD (3/8 in. x 5/8 in.)

medical grade silicone rubber pump tube.

Pump Body

Impact/corrosion resistant, glass reinforced Delrin

Vertical Lift

8.23 m (27 ft) maximum. Remote pump option recommended for lifts from 6.7 to

10.7 m (22 to 35 ft)

Sample Transport Velocity

61 mm/sec. (2 ft/sec.) minimum, at 4.6 m (15 ft) vertical lift in a 3/8 in. ID intake tube

Pump Flow Rate

60 mL/sec at 0.91 m (3 ft) vertical lift in a 3/8 in. ID intake tube

Sample Volume

Programmed in milliliters, in one mL increments from 10 to 9999 mL

Sample Volume Repeatability

From 0.3 to 6.7 m (1 to 22 ft) vertical lift +/-5 mL typical for a 100 mL sample (+/-

5%)

Sampling Modes

Supports 1 bottle. Composite Time, Composite Flow, and Level Actuation

Interval Between Samples

Selectable in single increments from 1 to 9999 flow pulses (momentary contact

closure 25 msec. or 5-12 V dc pulse; 4-20 mA interface optional), or 1 to 9999

minutes in one minute increments.

Intake Purge

Air purged automatically before and after each sample; duration automatically

compensated for varying intake line lengths.

Control Panel

18 key, 31 function membrane switch keypad with 18 character alphanumeric, liquid

crystal display. Self prompting/menu driven program.

Internal Clock

Indicated real time and date; 0.007% time base accuracy

Programmable Delay

Programmable sampler start time/date

Manual Sample

Initiates a sample collection independent of program process

Data Logging

Records program start time and date, stores up to 400 sample collection

times/dates, all program entries, operational status including number of minutes or

pulses to next sample, bottle number, number of samples collected, number

remaining, sample identification number.

Automatic Shutdown

Composite Mode: After preset number of samples have been delivered to

composite container, from 1 to 9999 samples, or upon full container.

Intake Tubing

6.4 mm (1/4 in.) and 9.5 mm (3/8 in.) ID vinyl to 9.5 mm (3/8 in.) ID Teflon-lined

polyethylene with protective outer cover

Intake Strainers

Choice of Teflon and 316 stainless construction, and all 316 stainless steel in

standard size and low profile for shallow depth applications

Power Requirements

12 V dc-supplied by optional ac power converter or battery. Average current draw

with pump running: 2.25 amps dc, without pump running: 4 mA dc

ac Power Backup

Rechargeable 6 amp-hour gel lead acid battery takes over automatically with ac

line power failure. Integral trickle charger maintains battery at full charge

Internal Battery

1.5 V

dc

lithium battery; maintains program logic and real time clock for five years.

Internal battery current draws less than 40 micro amps

Overload Protection

5 amp dc line fuse; ac power pack; internal 1 amp ac line fuse

Temperature Range

General use: 0° to 50° C (32° to 122° F). LCD display operated from –10° to 70° C;

Storage –40° to 80° C