Air filter maintenance, Troubleshooting – Harbor Freight Tools 67698 User Manual

Page 13

Page 13

For technical questions, please call 1-800-444-3353.

SKU 67698

Remove the Oil Drain Plug, allowing the

c.

oil to drain into the container.

When the oil is completely drained from

d.

the Pump, replace the Oil Drain Plug.

Fill the Pump with new compressor oil

e.

to the FULL level on the Oil Sight Glass.

Replace and tighten the Oil Fill Plug.

f.

Discard the old oil according to local,

g.

state and federal regulations.

Air Filter maintenance

Check the Air Filters weekly to see if they

need replacement. If working in dirty

environments, you may need to replace

the filters more often. To replace the Air

Filters:

Remove any cover that blocks access

a.

to the Air Filters.

Remove the Air Filters.

b.

Replace with new Air Filters.

c.

Replace the cover.

d.

reV 10h

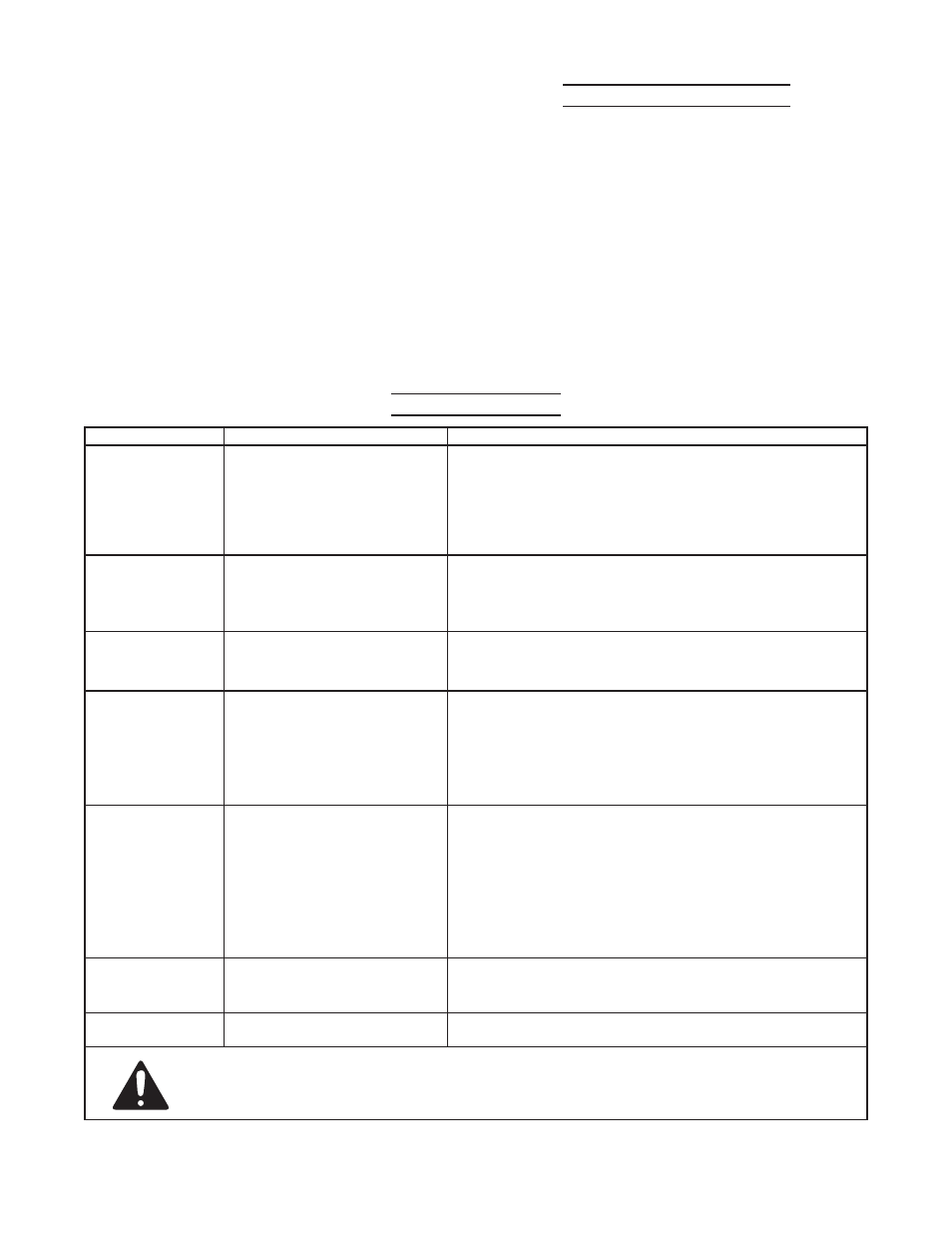

Troubleshooting

Problem

Possible Causes

likely solutions

Compressor builds

pressure too slowly

Crankcase overfilled with oil or

1.

oil too thick.

Working environment too cold.

2.

Loose fittings.

3.

Drain oil and refill to proper level with recommended oil.

1.

Move unit to a warmer location. Check that recommended oil

2.

is in crankcase.

Reduce air pressure, then check all fittings with a soap solution

3.

for air leaks and tighten as needed. Do not overtighten.

Compressor not

building enough air

pressure

Filters need cleaning/replacing.

1.

Crankcase oil too thick.

2.

Loose fittings.

3.

Check inlet and outlet filters. Clean and/or replace as needed.

1.

Drain oil and refill to proper level with recommended oil.

2.

Reduce air pressure, then check all fittings with a soap solution

3.

for air leaks and tighten as needed. Do not overtighten.

High Oil

Consumption

Crankcase oil too thin.

1.

Unit not on level surface.

2.

Crankcase vent clogged.

3.

Drain oil and refill to proper level with recommended oil.

1.

Reposition unit on a level surface.

2.

Clean Crankcase vent.

3.

Overheating

Filters need cleaning/replacing.

1.

Crankcase oil incorrect type

2.

and/or thickness.

Crankcase oil level too low.

3.

Unusually dusty environment.

4.

Check inlet and outlet filters. Clean and/or replace as needed.

1.

Drain oil and refill to proper level with recommended oil.

2.

Add oil to proper level, check for leaks.

3.

Clean and/or replace filters more often or move unit to cleaner

4.

environment.

Excessive noise

Crankcase overfilled with oil

1.

or oil is incorrect thickness or

type.

Crankcase oil level too low.

2.

Loose or damaged belt guard.

3.

Loose fittings.

4.

Unit not on level surface.

5.

Drain oil and refill to proper level with recommended oil.

1.

Add oil to proper level, check for leaks.

2.

Replace belt guard.

3.

Reduce air pressure, then check all fittings with a soap solution

4.

for air leaks and tighten as needed. Do not overtighten.

Reposition unit on a level surface.

5.

Oil in discharge air

Crankcase oil too thin or

1.

crankcase overfilled with oil.

Crankcase vent clogged.

2.

Drain oil and refill to proper level with recommended oil.

1.

Clean Crankcase vent.

2.

Air leaks from pump

or fittings

Loose fittings.

Reduce air pressure, then check all fittings with a soap solution for

air leaks and tighten as needed. Do not overtighten.

Follow all safety precautions whenever diagnosing or servicing the

compressor. disconnect power supply before service.