Nozzle & needle, Turbine unit, Trouble shooting problem cause action required – Earlex L0553 User Manual

Page 8

8

NOZZLE & NEEDLE

1.

Unscrew Air Cap (1).

2.

Remove the Air Cap (2).

3.

Completely remove Fluid Adjustment Screw (8).

4.

Remove the Spring (7).

5.

Push out the Needle (6) – do not use tools for this.

6.

Remove the Fluid Tip (4).

7.

Remove Fluid Tip Seal (5).

8.

Remove Spray Direction Plate(3).

9.

Place all of these items into a container and clean them using a brush and clean thinners.

10. Clean the inside of the gun.

11. Thoroughly dry these parts before reassembling.

12. Grease the Gland Seal (10).

13. Reassemble parts in reverse order. It is recommended fitting the Fluid Tip (4) prior to the needle.

NEVER DISPOSE OF PAINTS OR SOLVENTS INTO DRAINS. CONTACT YOUR LOCAL COUNCIL TO

ARRANGE COLLECTION OR FOR DETAILS OF NEAREST REGISTERED DISPOSAL SITE.

TURBINE UNIT

The turbine unit only requires minimal maintenance.

1.

Ensure its filter element is kept clean at all times.This is the filter underneath the main body. Disconnect

the unit from the mains, turn on side and remove foam material. This can be washed out if necessary and

replaced when dry. From time to time this filter will need replacing (part no.L0058).

2.

The turbine bearings are sealed and lubricated for life. There is no maintenance or adjustment required.

3.

Clean the turbine and hose unit with a damp cloth after use.

4.

The hose is stored by locating this into the clips on the side of the main body.

5.

The mains lead is stored by wrapping around the base of the unit and locating the plug in the space at the

back of the unit.

6.

The compartment on the top of the unit can be used for the storage of accessories.

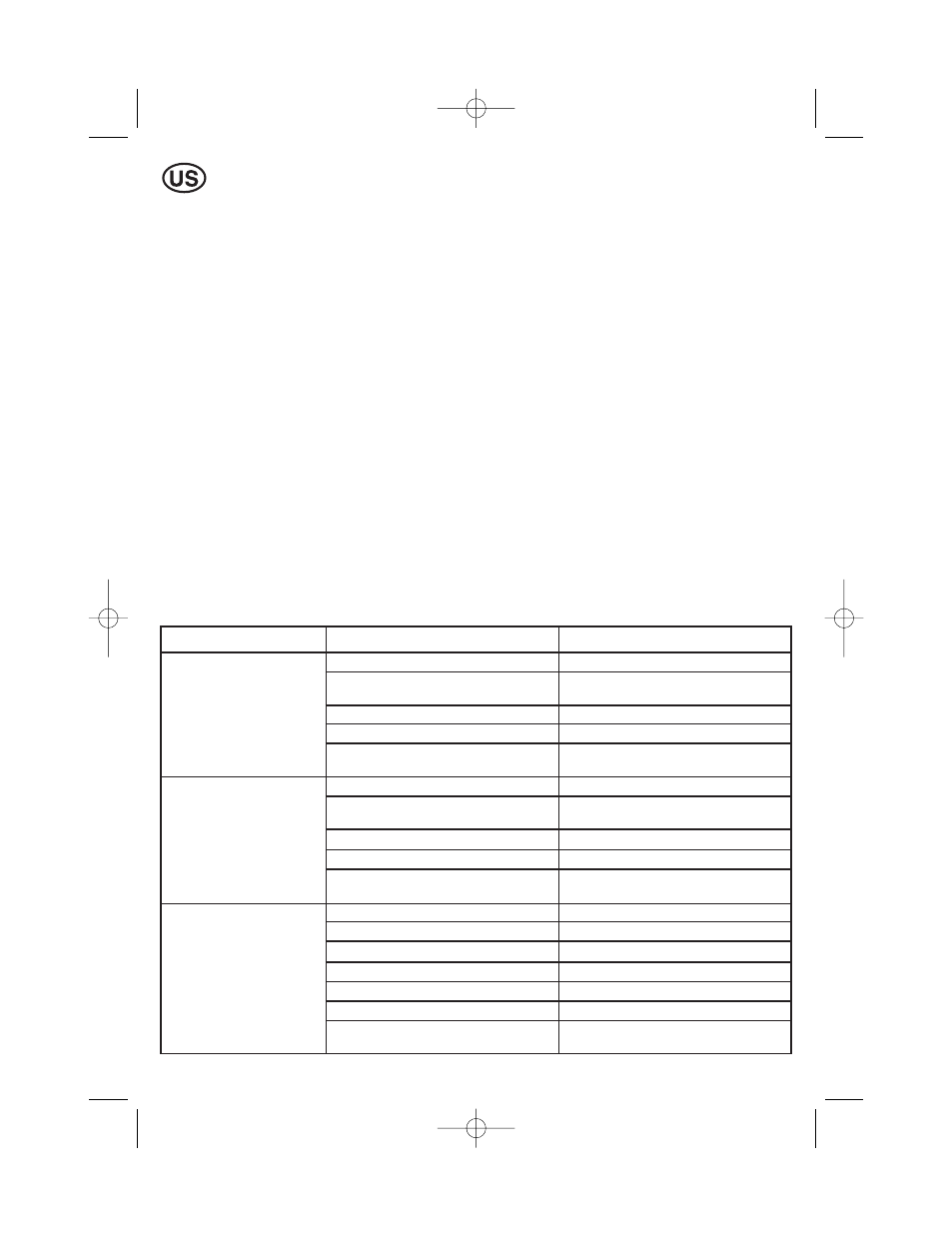

TROUBLE SHOOTING

PROBLEM

CAUSE

ACTION REQUIRED

The paint runs on the item

being sprayed

Paint too diluted

Add undiluted material

Paint volume too high

Reduce the paint flow with Fluid

Adjusting Screw (8)

Moving too slowly

Increase speed of application

Gun trigger being held for too long

Release Trigger earlier

Gun too close

Increase the distance between gun and

workpiece

Paint is thin or irregular

Paint too diluted

Add undiluted material

Paint volume too low

Increase the paint flow with Fluid

Adjusting Screw (8)

Moving too fast

Reduce speed of application

Gun clogged

Clean the gun

Gun too far away

Reduce the distance between gun and

workpiece

No paint being produced

Paint too thick

Add thinner

Gun clogged

Clean the gun

Pick up tube clogged

Clean Paint Feed Tube (11)

Air hose split

Replace air Hose (15)

Grainy paint

Filter the paint

Container almost empty

Refill Container

Gun at an angle

Ensure Paint Feed Tube (11) is angled

towards paint

L0553 (04-08) (US-FR-ES).qxd 20/6/08 2:25 pm Page 8