Electrolux 640793 User Manual

Hoods for combi steamers, Zanussi, Range composition

ZANUSSI

P R O F E S S I O N A L

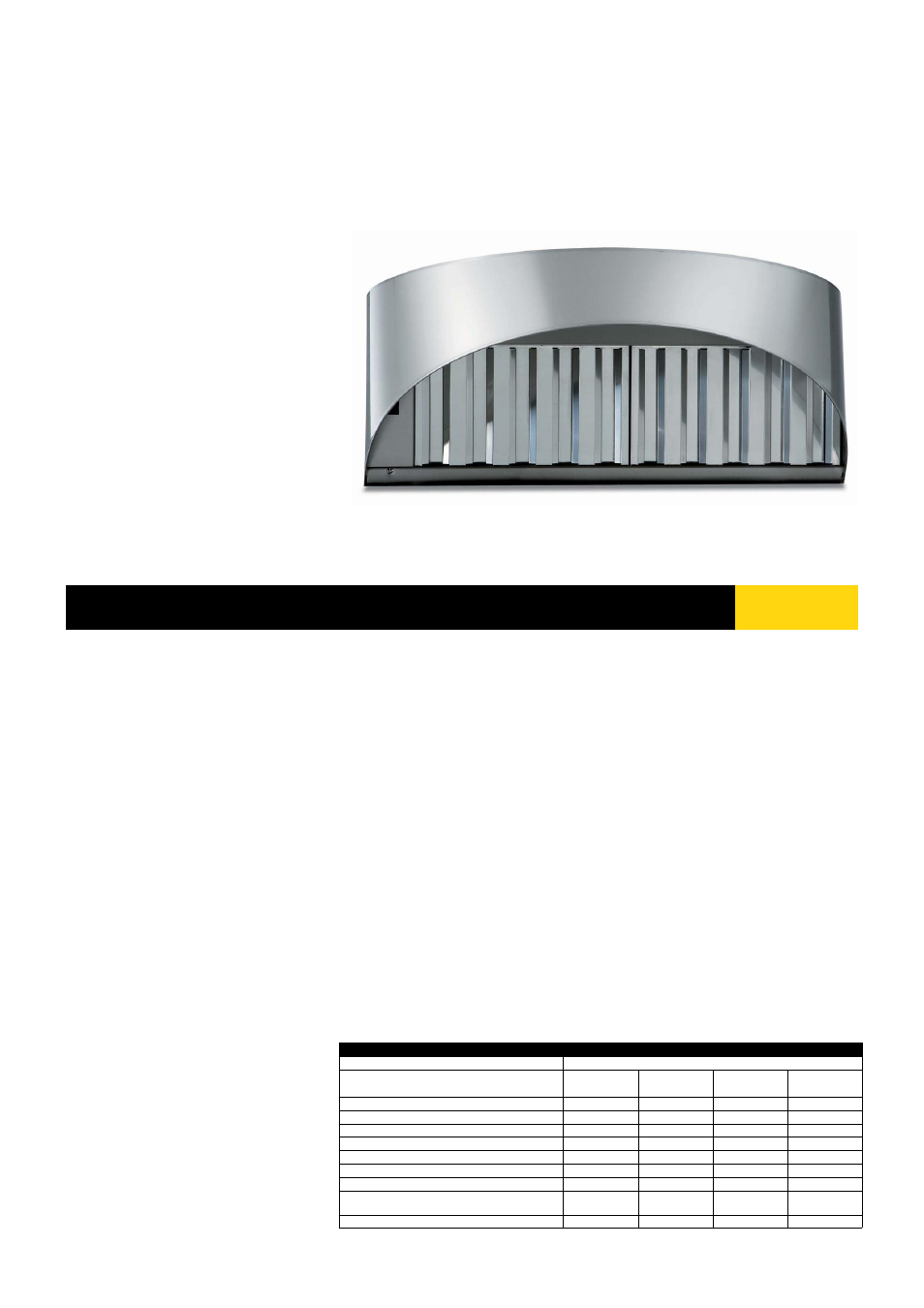

HOODS FOR COMBI STEAMERS

640791

304 S/S LABYRINTH FILTER H=250 MM

2

2

2

2

INCLUDED ACCESSORIES

Net weight - kg.

40

53

40

53

installed-electric

0.42

0.42

Power - kW

height

400

400

400

400

depth

1220

1220

1369

1369

width

895

895

1205

1205

External dimensions - mm

KLW610GEM

640791

KLWV610GEM

640792

KLW10GE21M

640793

KLWV10GE2M

640794

CHARACTERISTICS

MODELS

TECHNICAL DATA

RANGE

COMPOSITION

A range of central hoods which

guarantee a rational and versatile

solution to extraction problems that

may be present for most cooking

appliances. These hoods are

specially conceived for combi

steamers. The models detailed on

this sheet are 4 hoods for 6 and 10

GN 1/1 and 10 GN 2/1 combi

steamers, available in static or

ventilated version.

FUNCTIONAL AND

CONSTRUCTION

FEATURES

�

Built in AISI 304 stainless steel.

�

Static models:they have to be

connected through canalization to a

remote extractor.

�

On model with built-in fan, a

built-in humidity sensor automatically

activates the ventilation upon

opening of oven door and

automatically reduces the ventilation

as the humidity decreases, unitl a

minimal level of humidity is reached.

The system guarantees the correct

aspirated air flow based on different

working conditions as well as high

energy savings.

�

All models need a direct and

indipendent expulsion of the air to

the outside.

�

Endowed with “Dedalus” labyrinth

filter based on the fat centrifugal

filtration. The particular deflector

elements disposition forces the

intake air to change direction several

times. The air fattest particles bump

against filter elements and deposit

on their internal sides. The labyrinth

filter is easy to remove, providing

quick access to the descaling pipe.

�

The advantages of the 304 AISI

mechanical filters compared with the

traditional wire filters are:

- easy cleanibility in dishwashers thanks to

their smooth surfaces

- constant efficiency thanks to the never

obstructed filtering surface.

�

Equipped with exhaust gas outlet

chamber.

�

Exhaust nominal capacity 1.500 cubic

meters per hour.

�

Developed and produced in ISO 9001 and

ISO 14001 certified factory.

�

It is mandatory to install the flue

condenser 640413 ( for Gas Oven 6&10

Gn1/1) or 640415 (for Gas Oven 10 GN 2/1)

when using a gas oven