Troubleshooting guide – England's Stove Works 25-EPI User Manual

Page 35

Page | 35

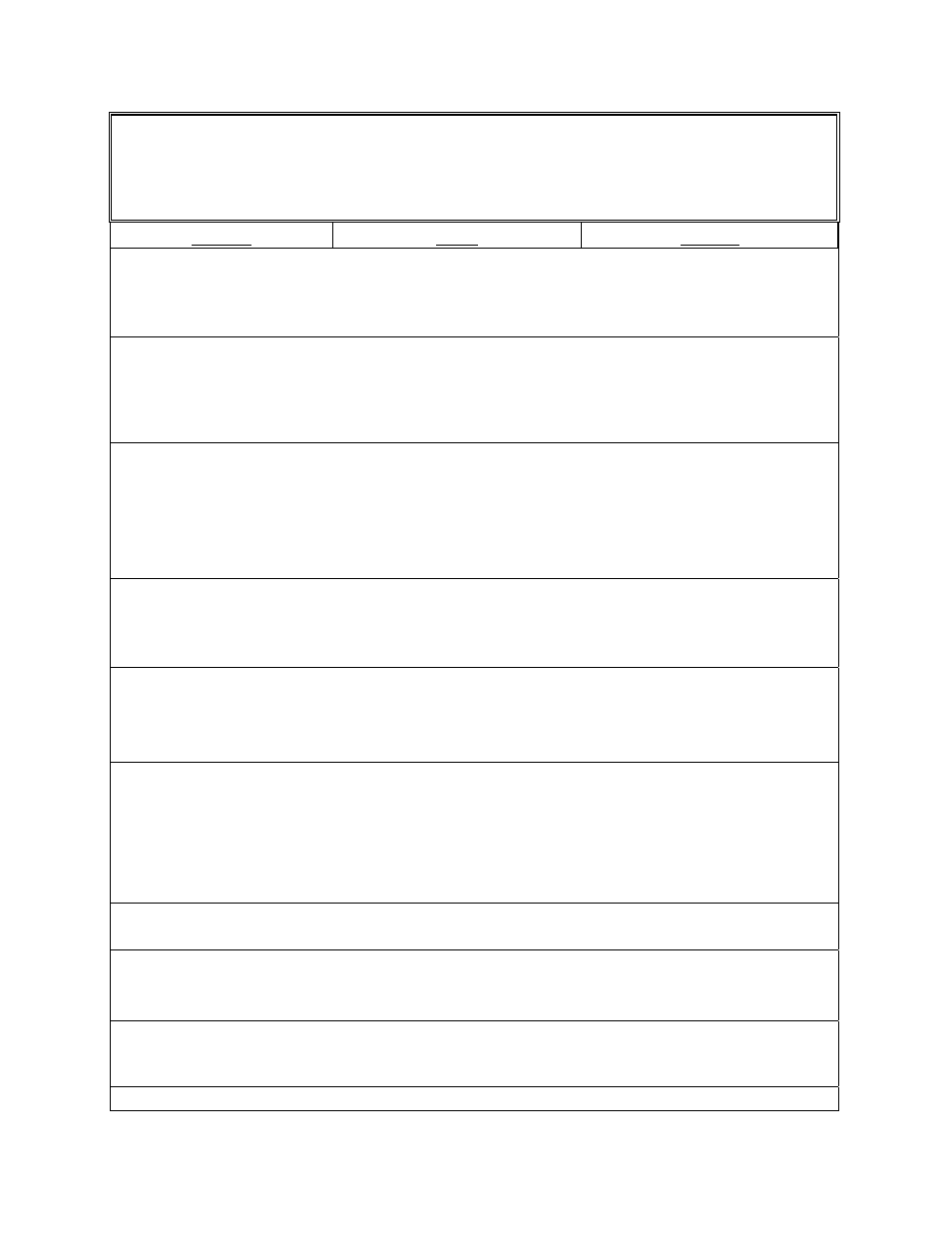

TroubleShooting Guide

WARNING: To avoid ELECTRICAL SHOCK always disconnect the unit from the power source BEFORE

attemping any repair. If this guide does not correct the problem, call your local dealer or Technical

Support at 1‐800‐245‐6489.

Problem

Cause

Solution

Auger not turning

1. Bad auger motor.

1. Replace auger motor.

2. Foreign matter jamming

auger.

2. Remove pellets and object.

3. Vacuum sensor.

3. Check exhaust blower.

Smoke smell or dust in

house

1. Improper exhaust connection.

1. Check exhaust connections for

leaks, especially the exhaust

blower connect. Seal leaks with

silicone, aluminum tape or a hose

clamp.

Room blower not operating

1. Loose thermal sensor.

1. Tighten connection on sensor.

2. Blower speed set higher than

heat range, causing stove to cool

and blower to cycle.

2. Lower blower speed.

3. Loose connection.

3. Check control board

connection.

Exhaust blower not

operating

1. Loose connection.

1. Check control board

connection.

2. Bad blower.

2. Replace blower.

3. Bad vacuum sensor.

3. Replace vacuum sensor.

Lazy Fire

1. Bad exhaust blower.

1. Inspect and replace blower.

2. Excessive pellet moisture.

2. Keep pellets dry.

3. Excessive ash build‐up.

3. Thoroughly clean unit.

4. Low quality pellets.

3. Use only PFI premium pellets.

Blown Fuse

1. Power surge.

1. Replace fuse; use surge

protector.

2. Exposed wire.

2. Check for exposed or frayed

wire and loose connections.

3. Electrical component shorting. 3. Check motors and blowers for

obstructions or short circuits.

High Pellet Consumption

1. Low quality or non‐uniformly

sized pellets.

1. Use premium pellets or try

another pellet brand.

Squeaking Noise

1. Obstruction in auger tube.

1. Check auger tube for foreign

objects.

2. Blower Noise.

2. Remove and oil blower.

Pinging or Rattling Noise

1. Foreign material in blower.

1. Check both blowers for

material.

2. Loose exhaust fan set screw.

2. Check set screw for tightness.

"E‐1" Code On Control Board 1. Vacuum bypass chip missing.

1. Contact Technical Support.