Mounting the engine, Throttle linkage, Attaching the fuel lines – Evolution Technologies 45GX2 User Manual

Page 3: Fuel for the evolution gas engine, Selecting a suitable propeller, Suggested propeller dimensions, 45gx 58gx, Aerobatics, Scale flying

Mounting the Engine

Most model airplane designs make provision for an engine

mount. It is extremely important that the engine mount be

securely attached to the airplane’s firewall and that the engine

is securely attached to the engine mount. Follow the instructions

included with the airplane for mounting the engine. The engine

should be fastened in place with 4 screws. Use 1/4” or 6mm

screws. If you decided to fasten the engine using a flexible motor

mount, always choose parts with enough solidity and strength.

Make sure all screws are tightened and regularly check that they

remain tight and in good condition.

Important: Air is necessary to cool the engine during operation.

Make sure that sufficient air circulation through the cowling is

provided. As a basic reference, the outlet area should be 3–5 times

the area of the inlet area to provide adequate cooling.

Throttle Linkage

Carefully attach the throttle linkage to the engine using a ball

link on the carburetor. Make sure that the linkage is free to

operate from low throttle to high throttle and confirm that the low

throttle setting on the transmitter closes the carburetor butterfly

to the low idle position. Adjust the length of the pushrod until full

throttle opens the carburetor butterfly fully, while low throttle, low

trim completely closes the butterfly.

Attaching the Fuel Lines

Use medium gasoline-compatible fuel line in the fuel tank as

well as the supply line to the engine.

Fuel for the Evolution Gas Engine

The Evolution gas engine has been designed to run on a mixture

of high-quality unleaded gasoline and synthetic oil intended for

racing 2-stroke gasoline engines. For the break-in period of the

new engine, mix the fuel in a ratio of 30 parts gasoline to 1 part

lubricant. After break in, use a ratio of 40 parts gasoline to 1

part lubricant.

Selecting a Suitable Propeller

The Evolution 45GX and 58GX have been designed to generate

maximum power at 6100–6300 rpm, according to the type

of exhaust used. If you wish to utilize the maximum power

output, choose a propeller which will allow the engine to reach

these revolutions, or slightly lower revolutions (The engine will

unload in the air depending on the aircraft speed and propeller

selected).

We do not recommend using propellers that allow the engine to

reach more than 7500 rpm on the ground.

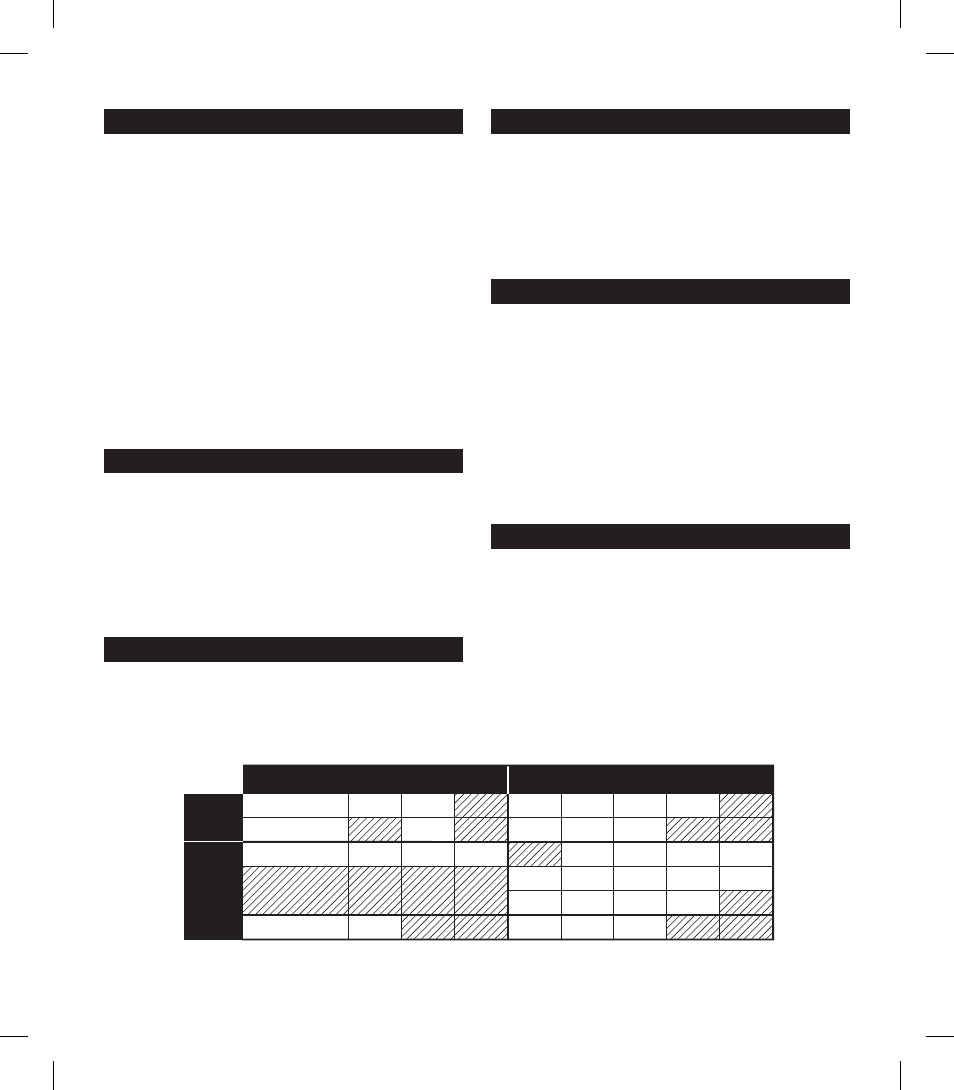

Suggested Propeller Dimensions

These engines (45GX2 and 58GX2) are designed for optimum

performance and torque when operated between 6100–6400

rpm. Choose your propeller according to the chart and to achieve

approximately 6300 rpm on the ground for best performance

and the lowest noise signature. Maximum horsepower occurs

between 7200–7400 rpm, but expect much higher propeller

noise at these tip speeds.

45GX

58GX

Aerobatics

Two-blade

Three-blade

Two-blade

Three-blade

Scale flying

22x10

26x8

26x10

21x10

24x10

24x12

22x8

23x8

23x10

24x8

24x10

21x12

22x8

22x10

22x12

24x9

24x10

24x8

24x9

24x10 24x12

25x7

25x8

25x9

25x10

26x7

26x8

26x9

26x10

25x12

8103.3_EVO_4558.manual.indd 3

6/16/06 10:23:13 AM