English – Elektra Beckum SPA 2001 W User Manual

Page 6

10

ENGLISH

used as a vacuum cleaner for vacuuming

deposited wood dust or chips, and

corresponds to applicable regulations, even

for oak and beech wood dust.

Here, the minimum volume flow is also

monitored at the pressure gauge. For a

cleaning nozzle with a connector diameter of

100 mm, the filter must be dedusted if the

pointer on the pressure gauge is in the red

area of the 100 mm extractor connection

piece diameter being used.

If the pointer of the pressure gauge is in the

red area, the filter must be cleaned.

Clean the machine after it has been used, the

filter should be dedusted a minimum of once

a day!

1) Switch off the wood-processing machine

2) Switch off the dust extractor at the on/off

switch (6)

3) Wait until the rotor on the ventilator

comes to a halt (otherwise cleaning will

be inadequate).

4) Actuate the cleaning lever (3) on the filter

housing several times.

If the pointer on the pressure gauge is still in

the red area after cleaning and start-up:

1) Check whether the maximum filling

capacity in the container (8) has been

reached (top edge of the top viewing

window (9)). If necessary, empty the

container (see Section 11).

2) Check whether the extraction hose is

blocked. (See Section 13).

3) Is the suction hose being used too long?

If necessary, reduce the suction hose to a

standard 2.5 m.

4) To avoid kinks and constrictions, do not

lay the suction hose around sharp

corners.

5) If the pointer is still in the red area, the

filter bag must be replaced (see Section

11).

Wear a dust mask (filter mask with

class 2 particle filter). Avoid

covering third parties with dust.

Dust must be only disposed of in

authorised locations (disposal as per local

regulations).

When the dust bag reaches the maximum

filling level in the container (level with the top

edge of the top viewing window) remove and

replace it with a new one.

Removing the full dust bag:

1) Secure the lockable machine roller.

2) Fold down both latches (1) simultane-

ously: The container is lowered.

3) Roll the container forwards.

4) Carefully close the dust bag.

5) Lift the dust bag from the container or tip

the container upside down and place it on

the ground - the dust bag can be removed

more easily using the second method.

6) Stand the container the correct way up

Inserting a new dust bag:

1) Insert new dust bag in the container

(make sure that the dust bag rests as

flush against the container wall as

possible) and fold approx. 6-10 cm over

the edge of the container minimising

creases while doing so.

2) The dust bag should rest flush in the area

around the viewing window so that the

filling level can be seen clearly.

3) Roll the container under the dust

extractor.

4) Close both latches (1) : The container is

raised and forms a tight seal with the dust

extractor.

After longer operating periods, the filter bag

slowly becomes clogged with fine dust

embedded deep in its pores. The cleaning

device can no longer remove this trapped

dust. In this case, the filter bag must be

replaced. Replacement filter, see Section 13.

The person replacing the bag must

wear a dust mask (filter mask with

class 2 particle filter) and

appropriate eye protection. Avoid

covering third parties with dust.

1) Pull out the mains plug

2) Secure the lockable machine roller.

3) Clean the filter thoroughly once more by

actuating the hand lever (3).

4) Fold down both latches (1) simultane-

ously: The container is lowered.

5) Roll the container forwards.

6) One recommendation here is to carefully

lay the dust extractor on its back in order

to reach the components more easily. If

the dust extractor is not laid on its back, a

ladder will be required.

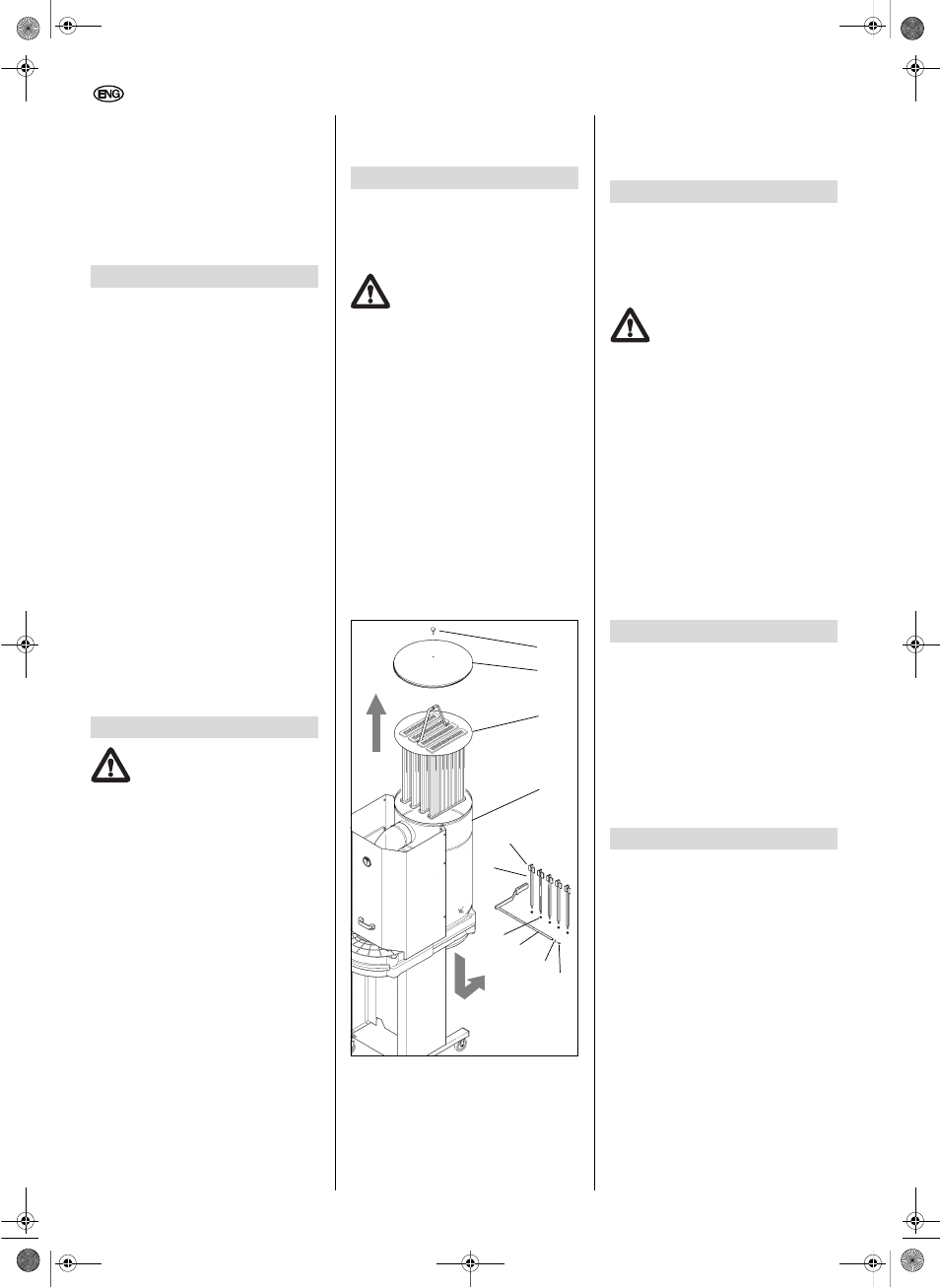

7) On the inside of the filter housing (d):

Unscrew the 5 hexagon nuts (g) (WAF

10) and remove the wiper arm (f) from the

vibration rod (h).

8) Replace worn wiper elements (e).

9) Loosen the screw (j) (Torx 20) and

remove together with the washer (i).

10) Remove vibration rod (h).

11) Unscrew star handle (a) on filter cover.

Remove filter cover (b).

12) Use a sharp knife to cut though the silicon

seal between the filter bag cover (c) and

the filter housing (d). Pull the filter bag

upwards and remove, place in a dust bag,

order no. 0913059433, close the dust bag

and dispose of in accordance with local

regulations.

13) Insert a new filter bag (c) - make sure the

vibration rod is in the correct position.

14) Apply new silicon sealing agent and leave

to harden/bond (min. 6 hours) - do not

switch on or move.

15) Assemble in reverse order.

Pointer on the pressure gauge is in the red

area: see Sections "10 Dedusting the filter",

"9 Monitoring the minimum volume flow rate"

If during operation the volumetric flow of the

dust extractor is considerably reduced or

stops altogether, the intake hose is probably

blocked.

Wear a dust mask (filter mask with

class 2 particle filter). To remove

the blockage, disconnect the hose

and take it outside or to a room with

extraction facilities. Hold the hose vertically or

hang it up. Beat the outside of the hose lightly

to loosen the dust clogged in the hose. This

activity must be carried out without harming

uninvolved third parties.

The dust extractor is fitted with an overload

protector that switches the dust extractor off

to prevent damage. Pinpoint and rectify the

cause. Then press the button (5) to return the

overload protector to its normal position.

The machine may experience temporary

reductions in voltage if mains power

conditions are unfavourable.

If the impedance at the connection point to

the public mains power supply is greater than

0.2 ohms, other measures may be required

before the machine can operate correctly at

this connection point.

If necessary, consult the local energy supply

company regarding impedance.

Filter bag set with fitted filter plate (as a

replacement) Order

no.

0913059441

Dust bags (pack of 10)

Order no. 0913059433

Suction hose (as a replacement), flame-

retardant, dia. 100 mm, 2.5 m in accordance

with Regulation ZH 1/139

Order no. 1013690533

Universal adapter

Order no. 0913031288

Cleaning nozzle

Order no. 0913031270

Transfer ring

Order no. 0913031300

Regular maintenance consists of three

inspections:

The following inspections should be

carried out on a daily basis:

Visual inspection to determine whether

− the machine or components thereof are

damaged.

− Suction performance check.

The following maintenance should be

carried out on a monthly basis:

Visual inspection to determine whether

− the machine or components thereof are

damaged.

− there are any leaks.

− the minimum volumetric control (pressure

gauge) is functioning correctly.

− Suction performance check.

The following general inspections should

be carried out on an annual basis:

Visual inspection to determine whether

− the filter is OK (dust indicator).

− the machine or components thereof are

damaged.

9 Dedusting the filter

10 Disposing of collected dust

11 Replacing the bag filter

a

b

c

d

e

f

g

h

i

j

12 Rectifying faults

13 Spare parts and accessories

14 Maintenance

SPA-Elektra.book Seite 10 Donnerstag, 10. April 2003 3:51 15