Warning, Maintenance, Reset after lockout and reset of safety thermostat – Enerco HS300ID User Manual

Page 4: Shut down

4

ENERCO GROUP, INC. |Indirect Fired Portable Heater

Operating Instructions and Owner’s Manual

•

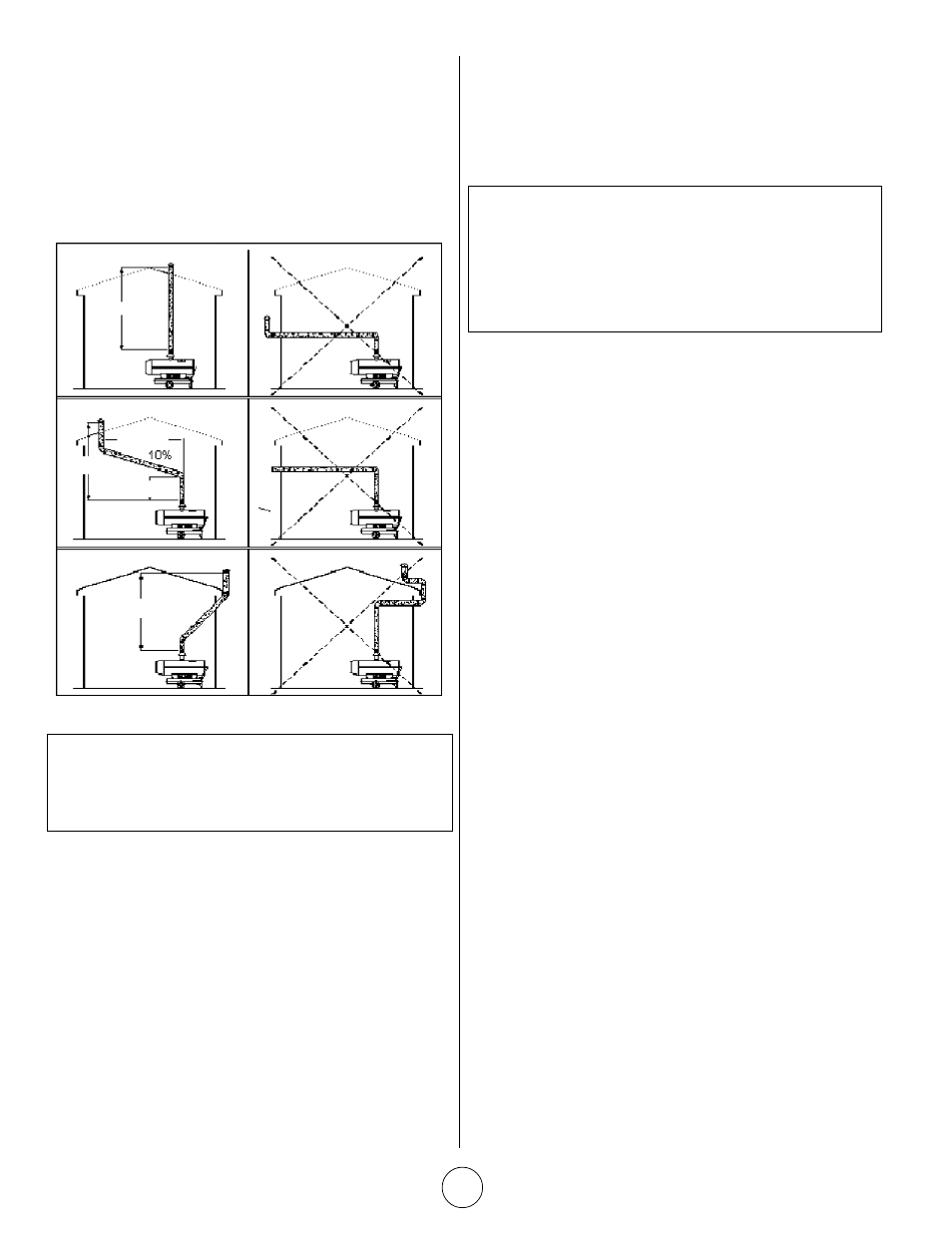

Indirect fired heaters: connect the heater to a chimney or to a

exhaust duct. To get a proper draft (at least .04 in WC) in the chimney

the exhaust gas path must rise. Avoid any elbows and bends in the

first part of the exhaust ducts for at least 10 ft. For operation of

heater in closed rooms without flue refer to the instructions for

installation (par. 4)

•

If a room thermostat is used, set maximum temperature on it.

•

Turn switch to position “ON”

•

Set the desired temperature on room thermostat.

WARNING!

Heaters equipped with heated nozzle do not start

immediately or may stop for some seconds after start. This is

normal and should not be considered a faulty condition.

Reset after lockout and Reset of safety

thermostat

•

The heater is equipped with a Reset pushbutton. When the

heater locks out, the red lamp on the pushbutton (fig.1, No.2)

lights up. In this case push the Reset button (see also the par.

“Troubleshooting”) to restart the heater.

•

The heater is also equipped with a manual reset safety

thermostat fixed in contact with the combustion chamber, that

can be reached through the inspection cover. To reset the

thermostat: unplug the heater, open the inspection cover and

push the reset button on the thermostat body.

Shut down.

•

Set switch to “OFF” to shut the flame off. The fan will go on

rotating for about 1’45” to cool the heater down. The fan motor

will automatically stop at the end of the aftercooling time, then

the unit can be disconnected from mains.

WARNING!

Never disconnect the supply plug to stop the

heater while in operation

The large amount of heat produced could damage the

components or activate the safety thermostat and

therefore make the unit not function

MAINTENANCE

•

Before carrying out any maintenance operation,

disconnect the power plug.

•

Maintenance must be carried out by qualified personnel

(see also par. 7)

•

The appliance must be thoroughly cleaned once a year to

ensure good combustion and long life.

•

Clean periodically

-

the oil spraying nozzle and its filter;

-

the oil pump filter

-

the main fuel filter cartridge

-

the ignition electrodes

-

the fan blades

-

the inside of the appliance, using compressed air

-

the flame sensor with a mild detergent

•

Periodically check cables and electrical connections

•

Check the oil filter and replace if necessary.

min 13 ft

max 33 ft

min 16 ft

min 10 ft

min 15 ft