Disassembly of valve block, Inspection, repair, and replacement, Assembly of valve block – Eaton Electrical PVE19 User Manual

Page 28: H. disassembly of valve block, Inspection, repair and replacement, J. assembly of valve block, I. inspection, repair, and replacement

28

H. Disassembly of Valve Block

1. Do not disassemble check valve parts (64) through

(66), unless action of the valve indicates a problem. Check

the valve action with a pencil or a screwdriver. Press the

check valve in against the spring, it should return and hold

firm against the seat. If the check valve is defective, remove

and replace the complete assembly. Press new seat (64)

flush with face of valve block. DO NOT scratch the face of

valve block (26).

2. Remove parts (67) through (73) from valve block (26).

NOTE

If bearing (32) was defective, perform the following

step.

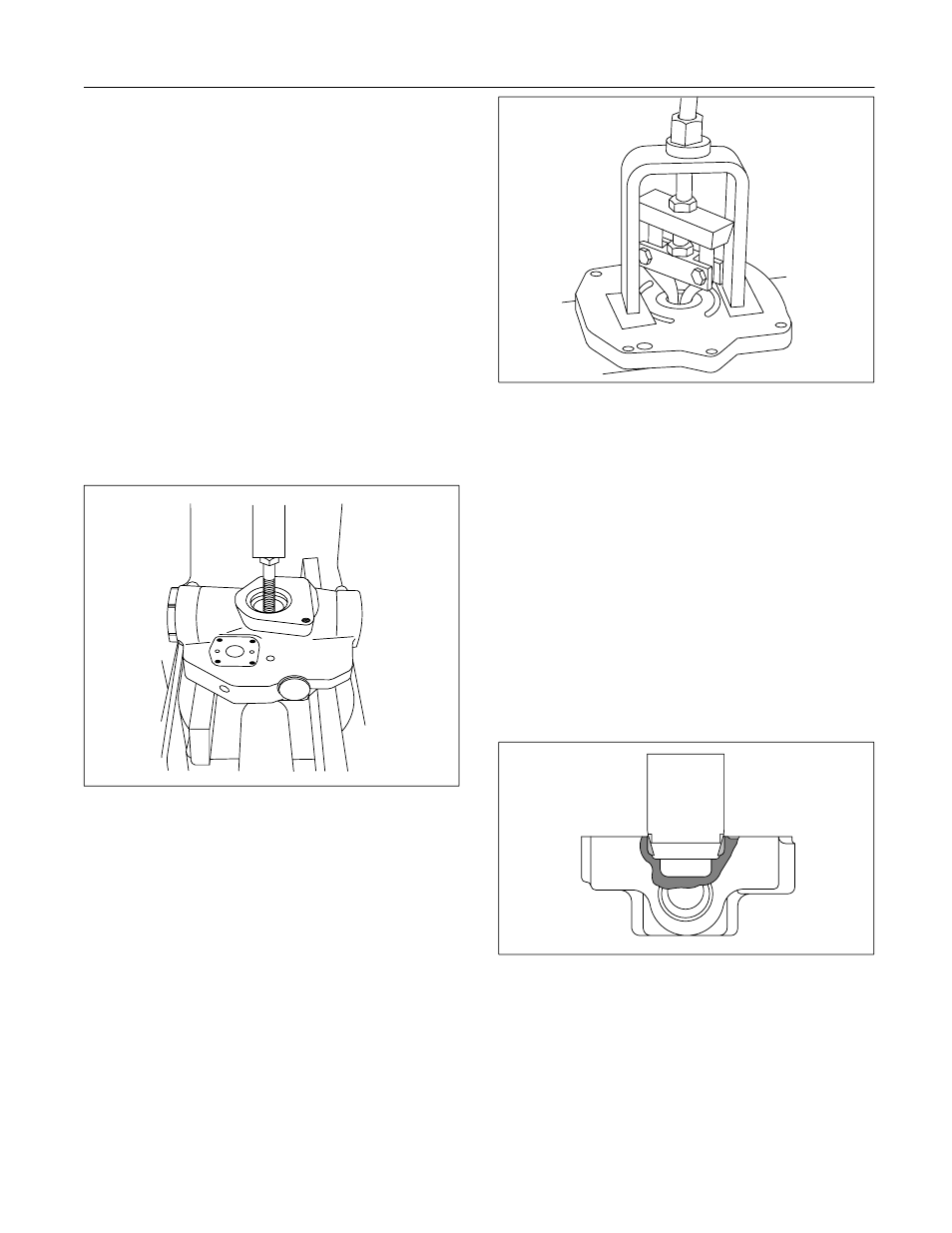

3. For PVE19/21, remove bearing race (63) from valve

block (36). The PVE12 roller bearing is in the valve block.

Refer to Figure 20 for removal information and use tool shown

in Figure 10 for PVE**G units. Use tool shown in Figure 10a

and procedure shown in Figure 20a for PVE** units with a

blind hole in valve block (26). BE CAREFUL not to scratch

face of the valve block during removal of the race.

Figure 20. Removal of Bearing Race from Valve Block.

I. Inspection, Repair, and Replacement

1. Clean all parts and place them on a clean sheet of

Kraft paper for inspection. Follow general procedure noted in

paragraph VI. GENERAL.

2. Inspect the threaded plugs for worn corners on the

hex head, stripped threads and burrs in the O–Ring groove.

Use an India stone to remove burrs. If threads are defective,

replace the plug.

3. Inspect compensator piston rod (73) for nicks and

burrs. Remove burrs and sharp edges with an India stone.

4. Inspect compensator piston (72) for wear at the area

of yoke contact. The compensator piston and the piston rod

are a close tolerance fit and must assemble together without

evidence of wear or bind. Rotate the piston through 360

°

when checking for bind.

Figure 20a. Removal of Bearing Race from valve Block

with Blind Hole.

5. Inspect valve block (26) for burrs, nicks, plugged body

passages, flatness of the pump wafer plate area and porosity.

Inspect check valve seat (64). Make sure the seat is tight with-

in the valve block and does not protrude above the valve block

face. Repair or replace the valve block if defective.

J. Assembly of Valve Block

NOTE

Refer to Figure 13 during the following assembly

procedures.

1. If bearing (32) was defective and bearing race (63 for

the PVE19/21) has been removed, a new bearing race must

be installed into the valve block. Refer to Figure 21 and

press a new bearing race in place with an arbor press. The

bearing race must bottom against the shoulder of valve block

at completion of press.

Figure 21. Installation of Bearing Race into Valve Block.

NOTE

Check flatness of the valve block face in the area

around each locating pin hole (31) and at bolt open-

ings (25). Use an India stone to remove burrs or

raised metal in these areas.