Firing enamel, Enameling on metal, Preparing the copper – Elmer's Glass Kiln User Manual

Page 12: Decorating the copper

Enameling

on Metal

Preparing the Copper

Enamels come in transparent or opaque. They can be

purchased directly from Thompson Enamel, P.O. Box 310,

Newport, Kentucky 41072. Their Lead Free Enamels come

ready to use. No enamel washing is required for these enam-

els.

Start with one of the many pre-shaped copper forms avail-

able, or shape and trim the copper to your own design.

1 Heat the copper on an enameling rack to about

1400°F/760°C to burn off oil or grease. Heat the

copper to just until smoke from oil or grease stops

coming off the metal and its color has changed to a

purple-red-pale green iridescence that moves

across the copper. This indicates that the grease

has vaporized. Do not fire the copper any longer than

this point. Otherwise excess fire scale will form,

making the next cleaning step difficult.

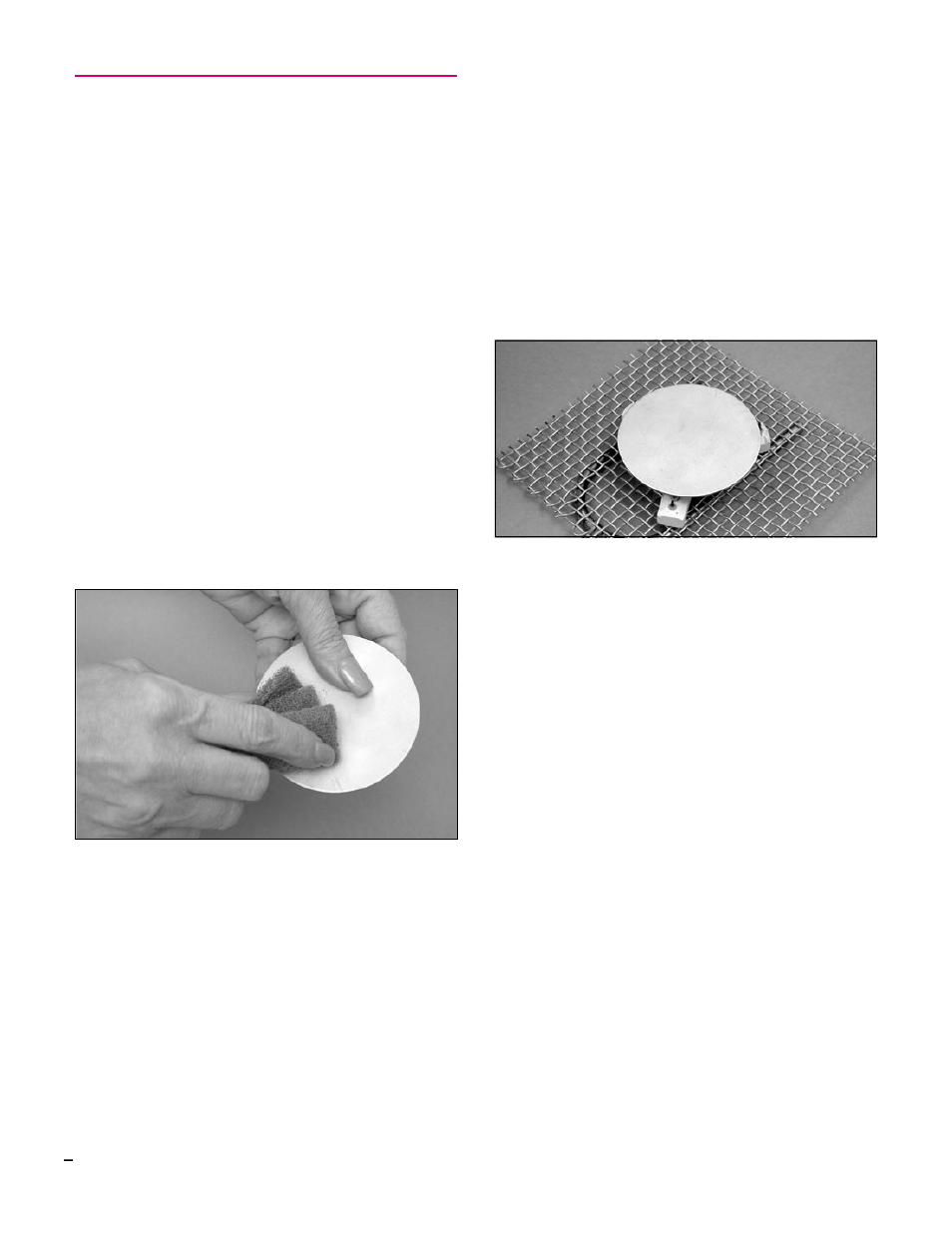

2 After the copper cools, brush any loose scale from

the copper. Use a brush or paper towel, being sure

that you do not put any grease or oil onto the copper,

such as fingerprints. Clean the copper with a 3M

Scotch-Brite® pad. This pad does such a good job

that in most cases no further cleaning will be re-

quired. Additional copper cleaning products are

available in the Thompson Enamel Catalog, includ-

ing Sparex No. 2.

It is best to clean the copper just before you decorate it. If

you wait too long to decorate after cleaning, the copper could

get dirty again.

Decorating the Copper

Counter Enameling

Most enameled pieces should be counter enameled on

the back side. This gives the piece a much more finished

look, it eliminates a great deal of fire-scale cleaning, and it

controls the chipping and cracking that can result from the

different rates of expansion and contraction in copper and

enamel after the enamel has been fired.

Counter or backing enamel, a mixture that gives a mot-

tled effect, can be used for counter enameling. Or you can

use regular enamel. Counter enamel is applied by the sifting

method described below.

When firing counter enamel, underfire it so that the fire

scale on the front of the piece isn’t too difficult to remove.

You can purchase a masking preparation from your supplier

to help prevent fire scale. You must place the piece on a stilt

when firing the other (front) side of the piece. The stilt pre-

vents the back of the counter enameled piece from sticking

to the enameling rack.

Applying Enamels

Apply enamel over a clean sheet of paper so you can pour

the excess back into the bottle for reuse. Transparent enam-

els should be applied in several thin coats. Transparent

enamels can be mixed with fairly good results. If opaque

enamels are mixed, however, a grainy effect results. The two

basic methods of applying enamels are sifting and spatula.

Sifting Enamel

Spray or brush Thompson holding agent onto the copper.

Then sift a 1/32” layer of enamel onto the copper. Use a #60

mesh sifter. If the coat is too thin, you can easily add another

coat after firing. But a coat that is too thick will bubble and

crack. The enamel must dry completely before firing.

Spatula or Inlaid Method

You can use this method to decorate a small area with

many different colors. Using a diluted solution of Thompson

holding agent, dampen the enamels just to the saturation

point, and maintain this moisture while working with the

enamels. Apply the enamels onto the copper with a small

spatula, and spread them out with a spreader to a coat of

about 1/32” thick. Lines of contact can be formed by the

spatula blade. Then spray the enamels with the holding

12