Motor, Components (fig. 1), Switch (fig. 1) – DeWalt DW297 User Manual

Page 2: Assembly, Mounting a socket (fig. 2), Side handle (fig. 1), Operation, Capacity, Maintenance, Cleaning

Motor

Your D

E

WALT tool is powered by a D

E

WALT-built motor. Be sure your power supply agrees

with the nameplate marking. Voltage decrease of more than 10% will cause loss of power and

overheating. D

E

WALT tools are factory tested; if this tool does not operate, check power

supply.

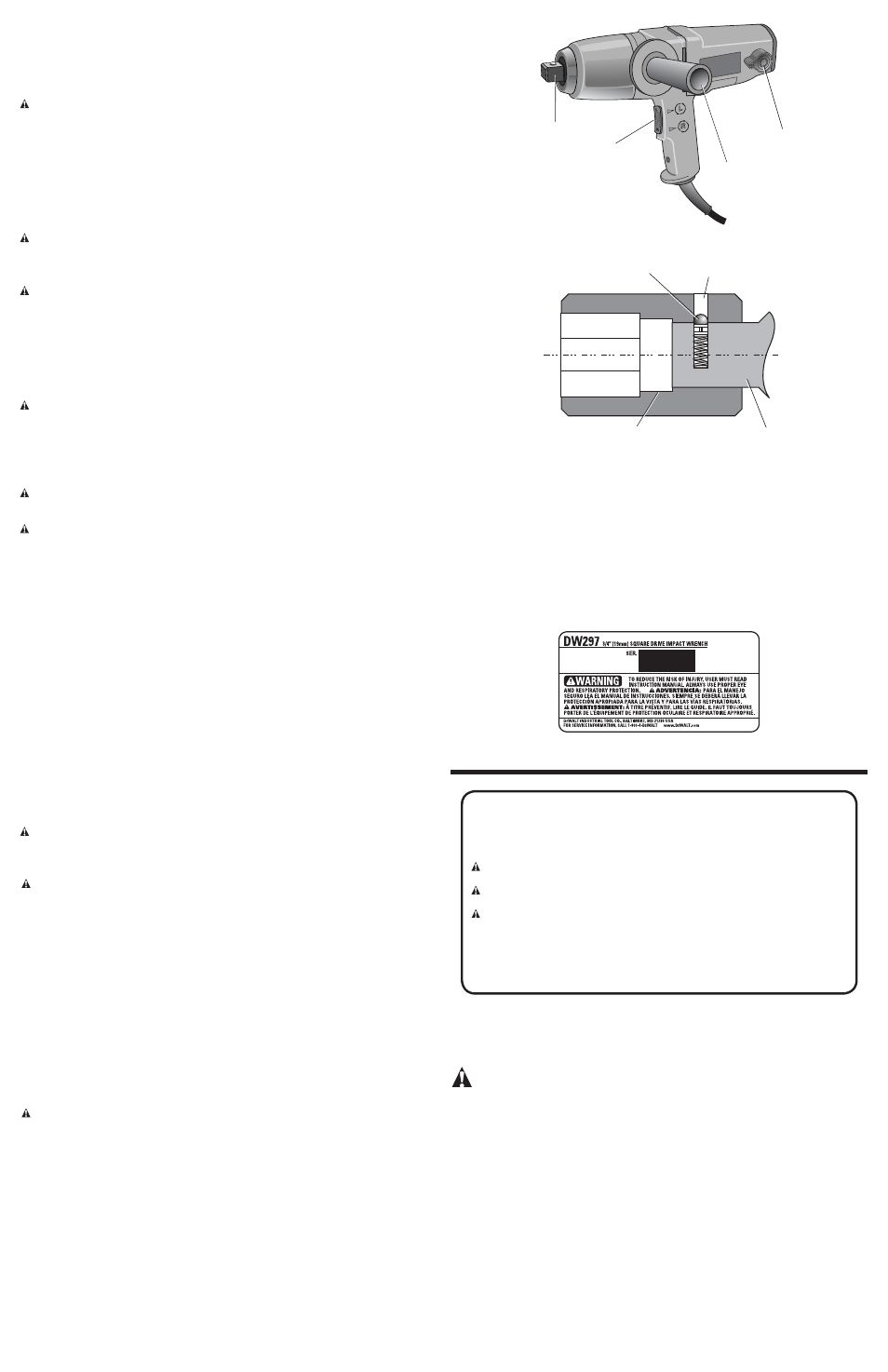

COMPONENTS (FIG. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Anvil

B. Trigger switch

C. Side handle

D. Brush inspection cap

Switch (Fig. 1)

The switch (B) in this machine functions as a motor switch and a rotational direction selector

switch. The lower part of the switch, marked with an R (right) will run the motor clock wise to

tighten a bolt. The upper part of the switch, marked L (left) will run the motor counterclockwise

to loosen the bolt. To stop the motor, release the switch.

CAUTION: Be sure to turn the switch OFF and wait until the motor comes to a complete stop

before changing direction of rotation. Switching direction of rotation while the motor is running

may cause serious damage to the tool and the operator may loose control.

ASSEMBLY

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

Mounting a Socket (Fig. 2)

To install a socket on the anvil (A), align the hole in the side of the socket (G) with the detent

pin (E) on the anvil. Press the socket on until the detent pin engages in the hole (F). To remove

a socket, depress the detent pin through the hole, using a small, pointed object, and pull the

socket off.

Side Handle (Fig. 1)

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed. Failure to do so may result in the side handle slipping during tool

operation and subsequent loss of control. Hold tool with both hands to maximize control.

Always use side handle (C). The position of the side handle attached to the hammer case can

be changed by unscrewing the handle (right hand threads). Relocate the handle to the desired

position and reinstall.

OPERATION

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

CAUTION: Ensure fastener and/or system will withstand the level of torque generated by the

tool. Excessive torque may cause breakage and possible personal injury.

Your impact tool generates 434 ft.-lbs. (60 kgm) output torque.

1. Place the socket on the fastener head. Keep the tool pointed straight at the fastener.

2. Press rocker switch to start operation. Always check torque with a torque wrench, as the

fastening torque is affected by many factors including the following:

• Voltage: Low voltage, due to generator or long extension cord, will reduce fastening

torque.

• Socket size: Failure to use the correct socket size will cause a reduction in fastening

torque.

• Bolt Size: Larger bolt diameters generally require higher fastening torque. Fastening

torque will also vary according to length, grade, and torque coefficient.

• Bolt: Ensure that all threads are free of rust and other debris to allow proper fastening

torque.

• Material: The type of material and surface finish of the material will affect fastening

torque.

• Fastening Time: Longer fasten ing time results in increased fastening torque. Using a

longer fastening time than recom mended could cause the fasteners to be overstressed,

stripped or damaged.

Capacity

Your 3/4" (19 mm) impact wrench uses sockets with 3/4" (19 mm) square drive ends. Both sizes

of impact wrenches are capable of driving the same range of hex impact sockets available. In

particularly heavy duty usage the 3/4" (19 mm) drive impact wrench has an extra strong anvil

that will resist breakage.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

Cleaning

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Motor Brushes (Fig. 1)

Be sure tool is unplugged before inspecting brushes. Carbon brushes should be regularly

inspected for wear. To inspect brushes, unscrew the plastic brush inspection caps (D, located

in the sides of the motor housing) and withdraw the spring and brush assemblies from the tool.

Keep brushes clean and sliding freely in their guides. Carbon brushes have varying symbols

stamped into them, and if the brush is worn down to the line closest to the spring, it must be

replaced. New brush assemblies are available at authorized D

E

WALT service centers.

Lubrication

Your tool was properly lubricated before leaving the factory. In from two to six months,

depending upon use, take or send your tool to a D

E

WALT certified service organization for a

complete cleaning, inspection and relubrication.

Tools used constantly on production or heavy duty jobs or exposed to heat may require more

frequent lubrication. Tools “out of service” for long periods should be relubricated before being

put back into service.

Accessories

WARNING: Since accessories, other than those offered by D

E

WALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only D

E

WALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact D

E

WALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-

D

E

WALT (1-800-433-9258) or visit our website www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a D

E

WALT factory service center,

a D

E

WALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

Three Year Limited Warranty

D

E

WALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

E

WALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

E

WALT tools are covered by our:

1 YEAR FREE SERVICE

D

E

WALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

E

WALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

E

WALT for a free replacement.

FIG. 1

B

D

A

C

FIG. 2

E

F

G

A

Définitions : lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

MISE EN GARDE : indique une situation potentiellement dangereuse

qui, si elle n’est pas évitée pourrait se solder par des blessures mineures ou

modérées.

MISE EN GARDE : utilisé sans le symbole d’alerte à la sécurité, indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée pourrait se solder par des

dommages à la propriété.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE RELATIF CET OUTIL OU À PROPOS

DE TOUT AUTRE OUTIL D

E

WALT, COMPOSER SANS FRAIS LE : 1 (800) 4-D

E

WALT

(1 (800) 433-9258)

Règles générales de sécurité concernant

les outils à piles

AVERTISSEMENT : Lire toutes ces directives. Tout manquement aux directives

suivantes pose des risques de choc électrique, d’incendie et/ou de blessure

grave. Le terme « outil électrique » dans tous les avertissements ci-après se rapporte

à votre outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

CONSERVER CES DIRECTIVES

1) SÉCURITÉ - AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner un outil électrique dans une atmosphère explosive, en

présence par exemple de poussières, gaz ou liquides inflammables. Les outils élec-

triques peuvent engendrer des étincelles qui pourraient enflammer toute émanation ou

poussière ambiante.

c) Tenir les enfants, ou toute autre personne, éloignés pendant l’utilisation d’un outil

électrique. Toute distraction pourrait vous faire perdre la maîtrise de ce dernier.

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit correspondre à la prise murale. Ne jamais

modifier la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec un

outil électrique mis à la terre. L’utilisation de fiches d’origine et de prises appropriées

réduira les risques de choc électrique.

b) Éviter tout contact corporel avec des éléments mis à la terre comme tuyaux,

radiateurs, cuisinières ou réfrigérateurs. Les risques de choc électrique augmentent

lorsque le corps est mis à la terre.