Installation – Desa BVDR18 User Manual

Page 8

www.desatech.com

901746-01E

8

INSTALLATION

Continued

CHECkING GAS CONNECTIONS

WARNING: Test all gas piping

and connections, internal and

external to unit, for leaks after

installing or servicing. Correct

all leaks at once.

WARNING: Never use an

open flame to check for a leak.

Apply a noncorrosive leak detec-

tion fluid to all joints. Bubbles

forming show a leak. Correct all

leaks at once.

PRESSURE TESTING GAS SUPPLY

PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect log set and its individual equip-

ment shutoff valve from gas supply piping

system.

2. Cap off open end of gas pipe where equip-

ment shutoff valve was connected.

3. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

4. Check all joints of gas supply piping sys-

tem. Apply a noncorrosive leak detection

fluid to all joints. Bubbles forming show a

leak.

5. Correct all leaks at once.

6. Reconnect log set and equipment shutoff

valve to gas supply. Check reconnected

fittings for leaks.

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

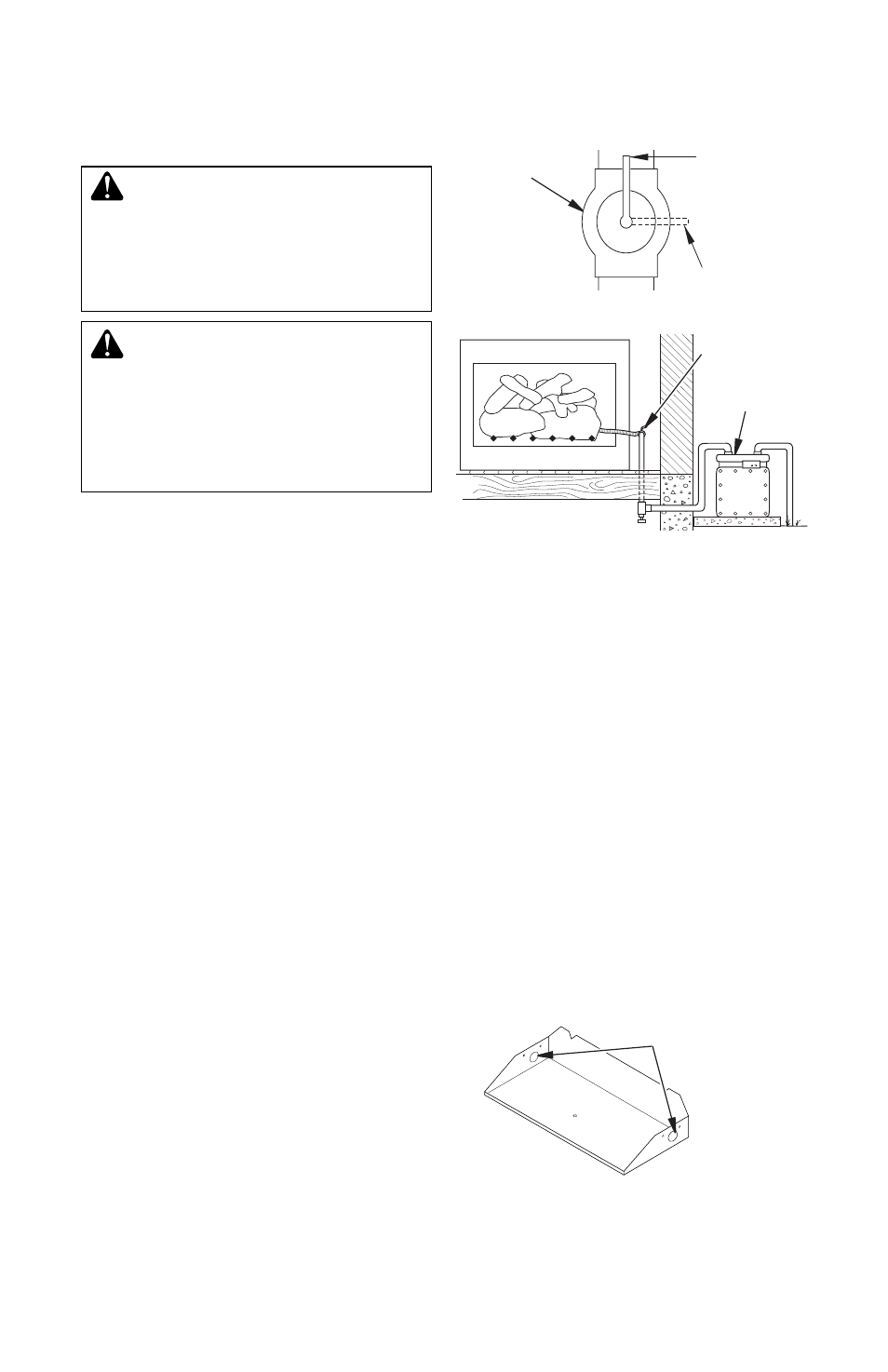

1. Close equipment shutoff valve (see

Figure 5).

2. Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

3. Check all joints from gas meter to equip-

ment shutoff valve (see Figure 6). Apply

a noncorrosive leak detection fluid to all

joints. Bubbles forming show a leak.

4. Correct all leaks at once.

Figure 6 - Checking Gas Joints

Gas Meter

Equipment

Shutoff Valve

HEARTH KIT ASSEMBLy AND

INSTALLATION

Kit Assembly

Note: The following instructions apply to

both standard single bar burners, as well as

dual flame “U” style burners. Be sure all pipe

threaded connections are tight, and have

thread compound to prevent leaks.

1. Determine which side the gas line will be

coming into the fireplace.

2. Using a hammer and screw driver, remove

knock-out plug from the side of the pan

that corresponds to the gas line (see

Figure 7).

3. Unscrew burner inlet fitting from burner

manifold (see Figure 8, page 9).

4. Place burner manifold in pan with thread-

ed opening facing open knock-out plug.

Figure 5 - Equipment Shutoff Valve

Open

Closed

Equipment

Shutoff

Valve

Knock-out

Plugs

Figure 7 - Knock-Out Plug Locations