Dukane – Dukane DPC 4 Welding System AN400 User Manual

Page 2

-

2

-

22102

DUKANE

A

A

p

p

p

p

l

l

i

i

c

c

a

a

t

t

i

i

o

o

n

n

N

N

o

o

t

t

e

e

AN400

© Dukane Corporation 2004. All rights reserved.

Dukane Corporation

2900 Dukane Drive Saint Charles, IL 60174 USA

Phone (630) 797-4900 FAX (630) 797-4949

http://www.dukane.com/us

Intelligent Assembly Solutions

2

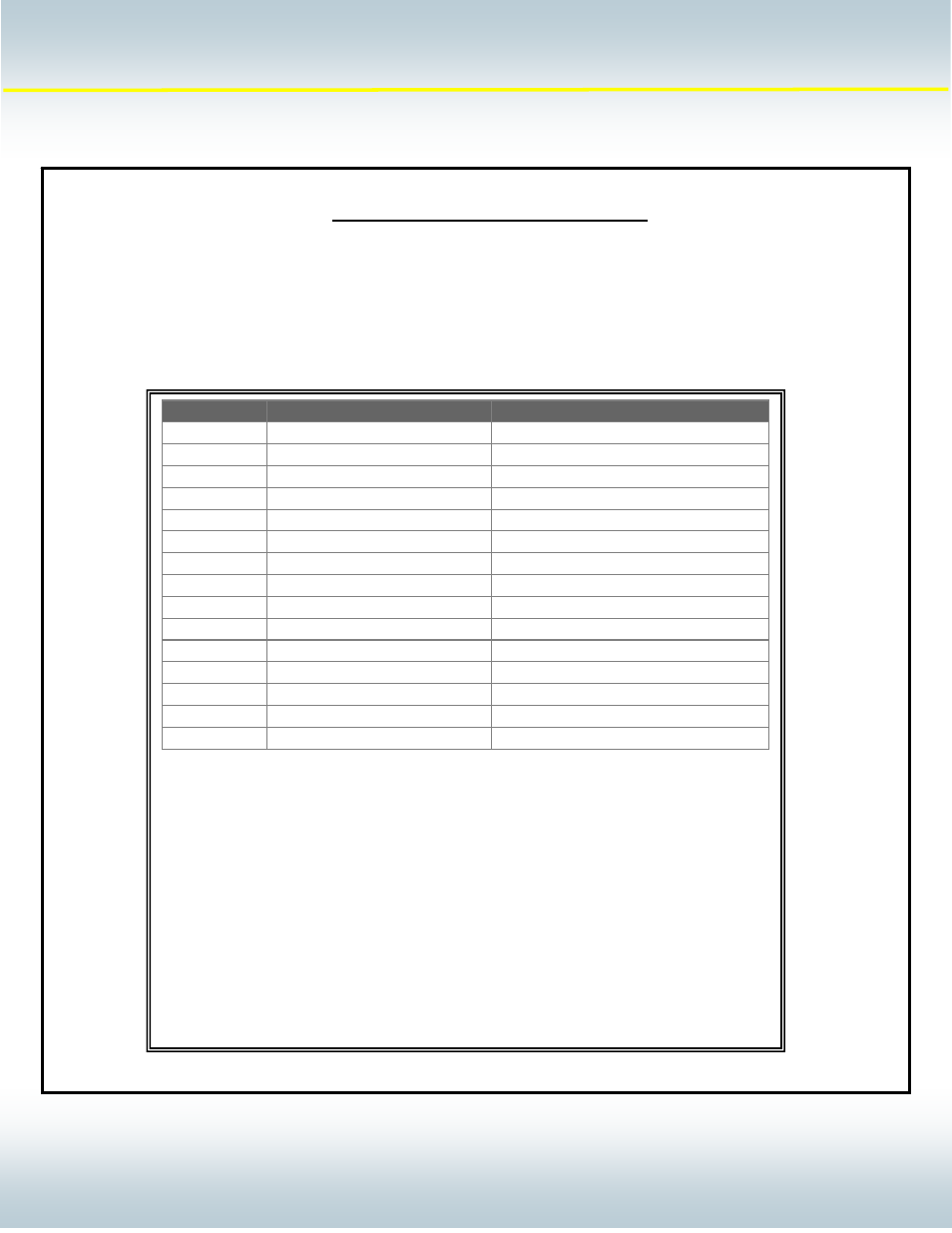

J602 User Interface Connector

The J602 User Interface connector is the primary communications link between the DPC IV and user automation

equipment. This connector provides status signals that can be used to monitor DPC weld data analysis results as well

as timing issues related to the processing of the weld sequence. It also provides the automation with dedicated

communication lines that allows the automation to control the beginning and the end of a welding sequence.

Pin Number

DPC Signal Name

DPC Signal Type

1 Power

Supply

+22 VDC (0.5 amp max)

2 Ground

Power Supply Return

3 Bad

Part

Output

4 Suspect Part (see note #2)

Output

5 Good

Part

Output

6 Ready (see note #1)

Output

7 Isolated

Output Common

Common Pin for Output Signals

8 Automation

Input

Input

9 Automation

Stop N/C

Input

10 Automation

Stop N/O

Input

11

Hand Probe Press Inhibit

Input

12 Input Common

Common Pin for Input Signals

13 Ground

Power Supply Return

14

15 Ground

Detect

Input

Note #1: This input can be reconfigured in the DPC IV menu choices to activate during

the following weld sequence event:

In

Cycle

Sonics

On

In

Hold

Note #2: This input can be reconfigured in the DPC IV menu choices to activate during

the following weld sequence event:

Network

Active

Sonics

On

Note: Please refer to the Hardware Setup section of the DPC IV manual for details on

reconfiguring pin 4 or pin 6 to the required status output signal.