Blade speed, Blade tracking, Removing and installing blades – DeWalt DWM120 User Manual

Page 2: Multi-position bail handle (fig. 1), Adjustments

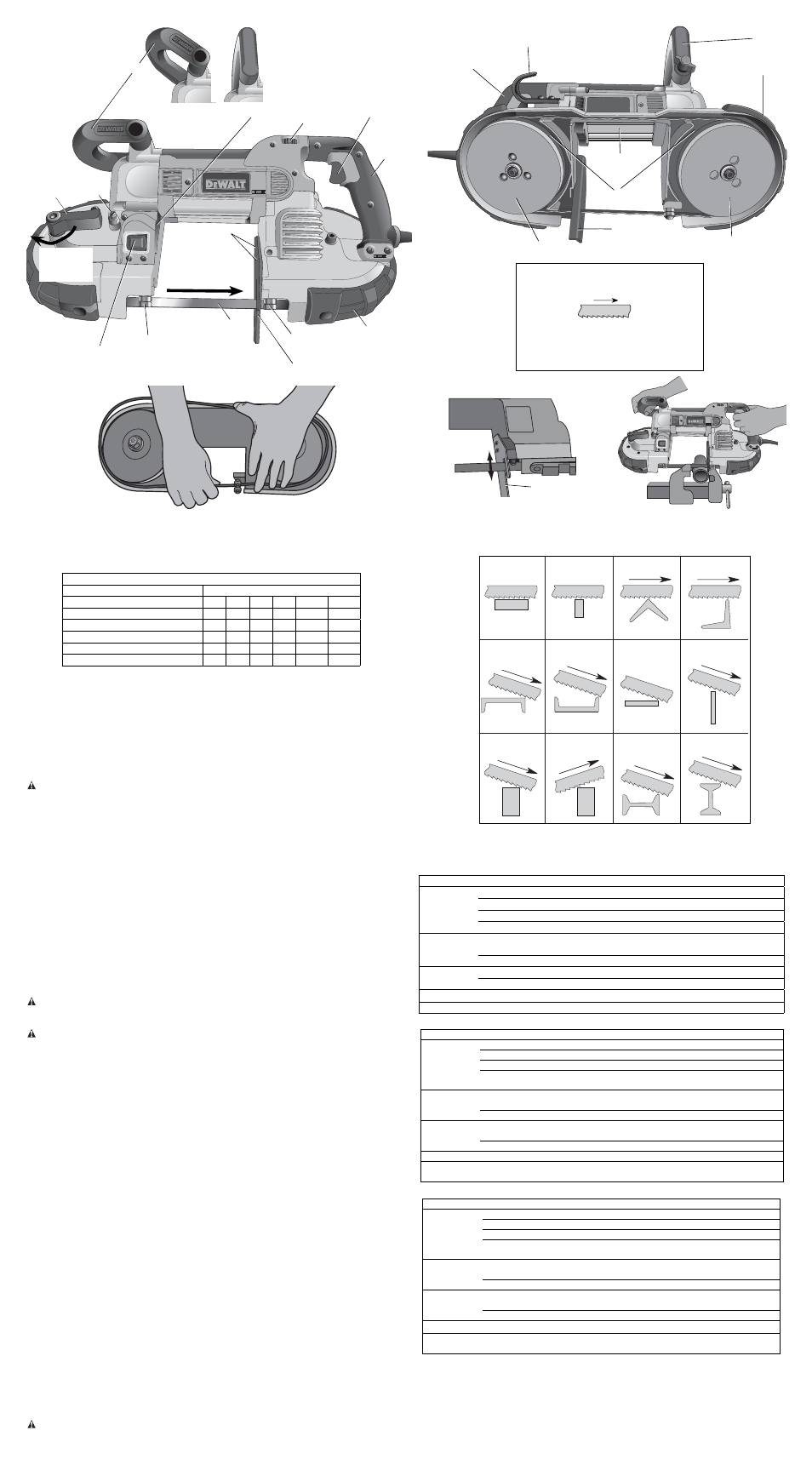

The following table is intended as a general guide only. Determine the type of material and

dimension of the workpiece and select the most appropriate band saw blade.

CAUTION: Never use the band saw to cut resin materials which are subject to melting. Melting

of resin material caused by high heat generated during cutting may cause the band saw blade

to become bound to the material, possibly resulting in overload and burn-out of the motor.

BLADE DESCRIPTION

Type of band saw blade

Bi-Metal

Number of teeth

24

18

14

10

14/18

10/14

Workpiece thickness

1/8" (3.2 mm) and under

•

•

1/8" - 1/4" (3.2 mm - 6.4 mm)

•

•

1/4" - 13/32" (6.4 mm - 10.3 mm)

•

•

13/32" (10.3 mm) and over

•

Blade Speed

Your DWM120 portable band saw is equipped with variable speed for greater versatility.

Turn the speed wheel (I) to select the desired speed (Fig. 1). Speed 1 is the slowest speed;

Speed 5 is the fastest. Use speed settings 1–5 when connected to an AC power supply.

When cutting copper, brass, bronze, aluminum, cast iron, angle iron, and mild steel, use a

higher speed.

When cutting plastic pipe, tougher steels, chrome steel, tungsten steel, stainless steel, and

other problem materials, use low speed.

NOTE: When cutting plastic pipe, higher speeds may melt plastic.

Blade Tracking

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories. An accidental start-up can cause injury.

Your band saw is equipped with an adjustable blade tracking mechanism which assures

proper blade tracking at all times. The back edge of a properly aligned blade will run

lightly against one or both of the back up rollers in the blade guides. (The pressure between

the edge of the blade and the roller will be very slight and will not damage either the blade

or the roller.)

TO ADJUST THE BLADE TRACKING

1. Use a 1/2" (13 mm) wrench to loosen the adjustment locking nut (G), shown in Figure 1

by turning it one or two turns counterclockwise.

2. Use a screwdriver to turn the tracking screw 1/4 turn. Turning the screw clockwise will

move the blade up toward the blade guide rollers. Turning the screw counterclockwise will

move the blade down away from the rollers.

3. Adjust so that the back edge of the blade lightly touches the rollers then securely

tighten the locking nut. (It will be necessary to plug the saw in and run it to observe the

tracking.)

4. Observe blade tracking between runs and repeat Steps 1–4 as necessary to achieve

proper blade tracking.

Removing and Installing Blades

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories. An accidental start-up can cause injury.

CAUTION: Cut Hazard. Blade tension lever is under spring pressure. Maintain control of

lever when releasing blade tension.

TO REMOVE BLADE (FIG. 1, 2)

1. Rotate the blade tension lever (H) clockwise until it stops to release tension in blade.

2. Turn the saw over and place it on a workbench or table with the cord to the left.

3. Begin removing the blade at the blade guard (M) and continue around the pulleys (L).

When removing the blade, tension may be released and the blade may spring free. SAW

BLADES ARE SHARP. USE CARE IN HANDLING THEM.

4. Inspect the guide rollers (F1, F2) and remove any large chips which may be lodged in

them. Lodged chips can prevent rotation of the guide rollers and cause flat spots on the

guide rollers.

5. Rubber tires (N) are mounted on the pulleys (L). The rubber tires should be inspected

for looseness or damage when changing the blade. Wipe any chips from the rubber tires

on the pulleys. This will extend tire life and keep the blade from slipping. If any looseness

or damage occurs, the tool should be brought to an authorized D

E

WALT service center

for repair or replacement as soon as possible. Continued use of the tool with loose or

damaged rubber tires will cause unstable travel of the band saw blade.

TO INSTALL BLADE (FIG. 1, 3–5)

1.

Position the blade so that the teeth are on the bottom and angled toward the work stop,

as shown in Figures 1 and 3.

2.

Slip the blade into the guide rollers, as shown in Figure 4.

3.

Holding the blade in the guide rollers, place it around both pulleys (L) and through the

work stop (E), as shown in Figure 5.

4.

Make sure that the blade is fully inserted into the guide rollers and positioned squarely

against the rubber tires.

5. Rotate the blade tension lever (H) counterclockwise until it stops and then gently turn the

saw over so that the pulleys rest on your work bench or table and. Make sure the teeth

face away from the bandsaw (Fig. 1, 3).

6. Turn the speed wheel to low speed (1) and then turn the saw on and off a few times to

ensure that the blade is seated properly.

Multi-position Bail Handle (Fig. 1)

A bail handle is provided for carrying the tool and for use as an additional handle. Assemble

the bail handle in one of the milti-positions (forward, 45º or straight up) shown in Figure 1.

When adjusting the bail handle from one position to the other, loosen the bail handle knob and

move the handle to one of the three positions and tighten knob.

Adjustments

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories. An accidental start-up can cause injury.

FIG 4

FIG. 5

E

YES / OUI / SÍ

NO / NON / NO

FIG. 7

RECOMMENDED CUTTING POSITIONS / POSITIONS DE COUPE

RECOMMANDÉES / POSICIONES DE CORTE RECOMENDADAS

FIG. 6

YES / OUI / SÍ

YES / OUI / SÍ

YES / OUI / SÍ

YES / OUI / SÍ

YES / OUI / SÍ

NO / NON / NO

NO / NON / NO

NO / NON / NO

NO / NON / NO

NO / NON / NO

Item

Model

DWM120

Motor

Type

Protected type, series commutator motor

Power source

single-phase, AC 60Hz

Voltage

120 volts

Full-load current

10 amp

Band Saw

Blade

Dimensions

1/2" x 44-7/8" x .020"

(12.5 mm x 1140 mm x .5 mm)

Peripheral speed

100 - 350 ft/min (30 - 106 m/min)

Max. Cutting

Dimensions

Pipe outer dimensions

4-3/4" (120.7 mm)

Stock

5" x 4-3/4" (127 mm x 120.7 mm)

Net Weight

15 lbs. (6.8 kg)

Cord

3 conductor type captive cable 8.0 ft. (2.4 m)

L

J

A

D

L

E

K

FIG. 2

M

N

FIG. 1

A

B

D

E

F1

I

H

C

J

O

P

R

LOOSEN

DESSERRER

AFLOJE

F2

G

BLADE DIRECTION

DIRECTION DE LA LAME

DIRECCIÓN DE LA HOJA

STRAIGHT UP

TOUT DROIT

HACIA ARRIBA

45º

FIG. 3

BLADE DIRECTION

DIRECTION DE LA LAME

DIRECCIÓN DE LA HOJA

POSITION OF TEETH ON LEFT SIDE OF MACHINE

POSITION DES DENTS SUR LE CÔTÉ

GAUCHE DE LA MACHINE

POSICIÓN DE LOS DIENTES EN EL LADO

IZQUIERDO DE LA MAQUINA

Article

Modèle

DWM120

Moteur

Type

Type protégé, série moteur à collecteur

Source de courant

monophasé, CA 60Hz

Tension

120 volts

Courant de pleine

charge

10 amp

Lame de

scie à ruban

Dimensions

12,5 mm x 1140 mm x 0,5 mm

(1/2 po x 44-7/8 po x 0,020 po)

Vitesse périphérique

30 - 106 m/min (100 - 350 pi/min)

Longueurs

max. de

coupe

Dimensions externes

de tuyau

120.7 mm (4-3/4 po)

Bois spéciaux

127 mm x 120.7 mm (5 po x 4-3/4 po)

Poids net

6,8 kg (15 lb)

Cordon

Cordon à 3 broches et 3 conducteurs

de 2,4 m (8 pi)

Artículo

Modelo

DWM120

Motor

Tipo

Tipo protegido, serie de motor commutador

Alimentación Eléctrica

Corriente alterna de 60Hz, monofásica

Voltaje

120 voltios

Corriente a carga

completa

10 amperios

Hoja de la

Sierra de

Banda

Dimensiones

12.5 mm x 1140 mm x .5 mm

(1/2 pulg. x 44-7/8 pulg. x .020 pulg.)

Velocidad periférica

30 - 106 m/min (100 - 350 pie/min)

Máx.

Dimensiones

de Corte

Dimensiones externas

de tubería

120.7 mm (4-3/4 pulg.)

Reserva

127 mm x 120.7 mm (5 pulg. x 4-3/4 pulg.)

Peso Neto

6,8 kg (15 lbs)

Cable

3 Cables tipo cautivos conductores

de 2,4 m (8,0 pie)