Model 3vg80, Theory of operation, Propane supply – Dayton 3VG80 User Manual

Page 5

Version B - For Reduction

G016.J

®

Dayton Operating Instructions and Parts Manual

5

Model 3VG80

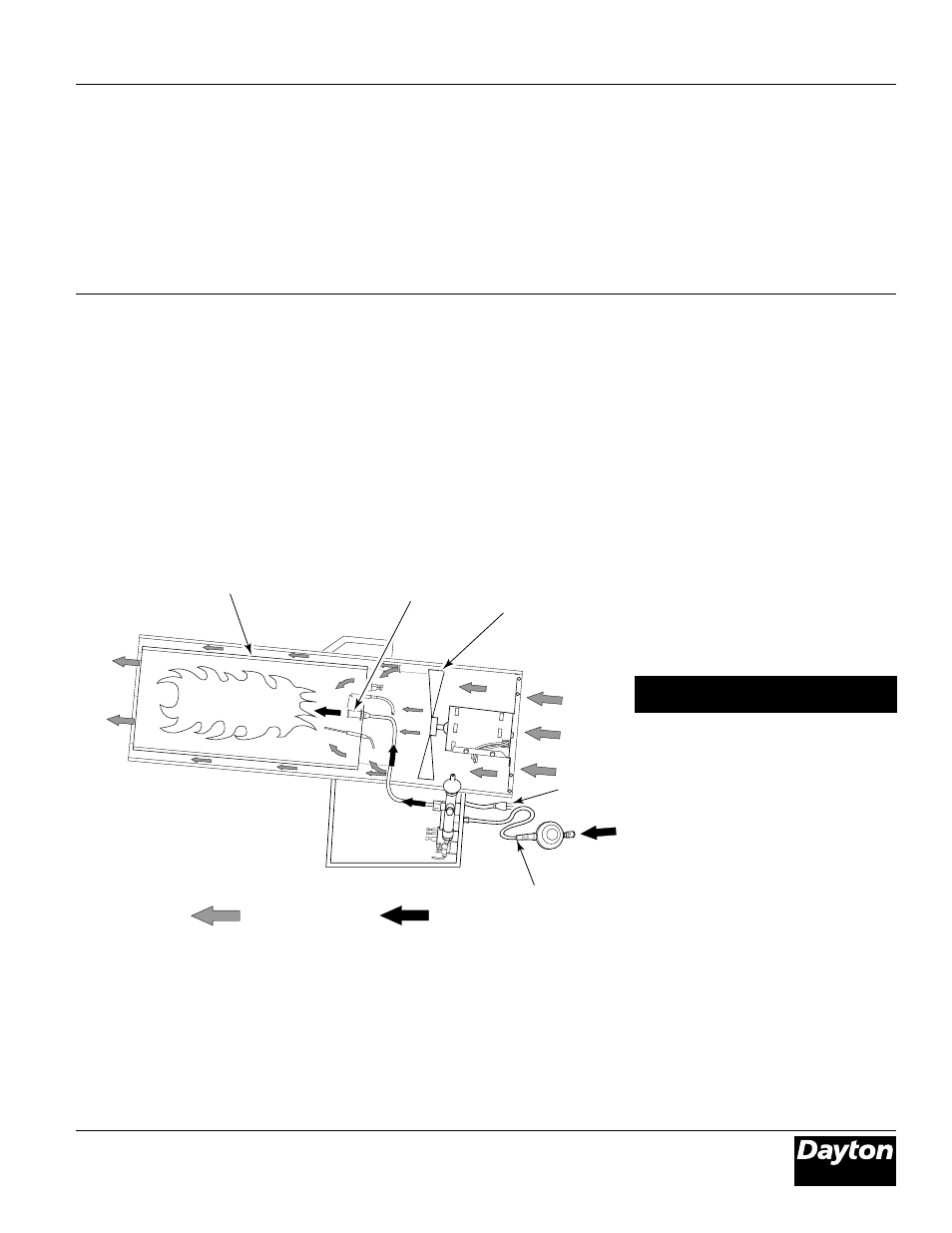

Air For Combustion

And Heating

Fuel

Combustion Chamber

Figure 3 - Cross Section Operational View

Clean

Heated

Air Out

(Front)

Hose/Regulator

Assembly

Nozzle

Fan

Cool Air

In (Back)

Power

Cord

THE FUEL SYSTEM

The hose/regulator assembly attaches to

the propane gas supply. The propane gas

moves through the automatic control valve

and out the nozzle.

THE AIR SYSTEM

The motor turns the fan. The fan pushes

air into and around the combustion

chamber. This air is heated and provides a

stream of clean, hot air.

Theory of Operation

Air for

Combustion and

Heating

Fuel

Propane Supply

Propane gas and propane tank(s) must be

provided by the customer.

Use this heater only with a propane vapor

withdrawal supply system. See Chapter 5

of the Standard for Storage and Handling

of Liquefied Petroleum Gas, ANSI/NFPA 58.

Your local library or fire department will

have this booklet.

The amount of propane gas ready for use

from propane tanks varies. Two factors

decide this amount:

1. The amount of propane gas in tank(s)

2. The temperature of tank(s)

The chart below shows the number of 100

pound tanks needed to run this heater.

Less gas is vaporized at lower tempera-

tures. You may need two or more 100

pound tanks or one larger tank in colder

weather. Your local propane gas dealer will

help you select the proper supply system.

The minimum surrounding air temperature

rating for each heater is -20°F (-29°C).

Temperature (ºF)

Number of tanks,

at Tank

100,000 Btu/Hr

32°

2

20°

3

10°

3

0°

3

-10°

Use Larger Tank

-20°

Use Larger Tank

THE IGNITION SYSTEM

The spark transformer ignitor lights the

main burner.

THE AUTOMATIC CONTROL SYSTEM

This system causes the heater to shut

down if the flame goes out.