Operating controls and adjustments – Delta 31-392 User Manual

Page 10

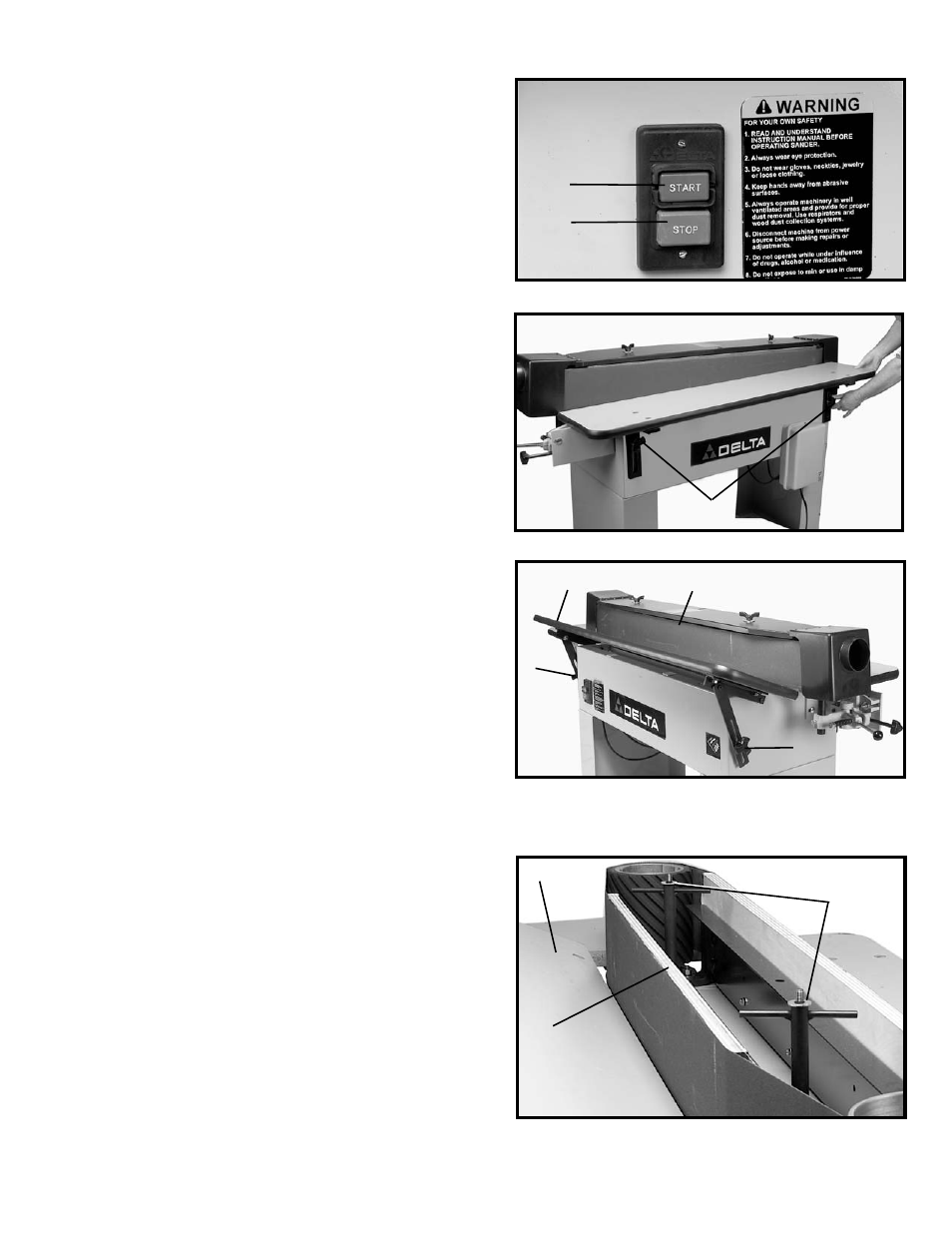

STARTING AND STOPPING EDGE

SANDER

To start the tool, push the start button (A) Fig. 25; to stop

the tool, push stop button (B).

ADJUSTING TABLE POSITION

To raise or lower the straight table, loosen lock knobs (A)

Fig. 26, adjust table height and tighten knobs (A). NOTE:

When straight sanding, it is advisable to raise one end of

the table so it is higher than the other, as shown. This

allows for cooler belt running and less material burning.

It also prolongs belt life, provides effici- ent sanding and

will prevent spot wear on the belt surface. CAUTION:

MAKE CERTAIN THE SANDING BELT IS NOT IN

CONTACT WITH THE TABLE BEFORE STARTING THE

MACHINE.

ADJUSTING TILTING TABLE

The tilting table (A) Fig. 27, can be tilted by loosening two

lock knobs (B) on each side of the table. Once the angle

of tilt has been set, tighten lock knobs (B).

The tilting table allows for bevel sanding operations to be

performed and reduces the amount of friction on the

sanding belt when edge sanding certain shapes.

CAUTION: AFTER SETTING THE ANGLE OF TILT ON

THE TABLE, MAKE CERTAIN THE SANDING BELT IS

NOT IN CONTACT WITH THE TABLE. If the table is in

contact with the sanding belt, the shorter straight platen

(C) must be adjusted.

ADJUSTING SHORT PLATEN

To adjust the short platen when sanding on the tilting

table, proceed as follows:

1. DISCONNECT TOOL FROM THE POWER SOURCE.

2. Remove the top guard and dust chute assembly.

3. Turn studs (A) Fig. 28, counterclockwise to loosen

platen (B).

4. Adjust platen (B) Fig. 28, until the sanding belt is close

to, but not contacting tilting table (C). Tighten studs (A)

Fig. 28, after adjustments are made.

5. Reassemble top guard and dust chute assembly to

edge sander.

OPERATING CONTROLS AND ADJUSTMENTS

10

Fig. 25

Fig. 26

Fig. 27

Fig. 28

A

B

A

C

B

B

A

A

C

B