DeWalt DW400 User Manual

Page 9

1. To start the tool, slide the ON/OFF

switch (A) toward the front of the tool.

2. To stop the tool, release the ON/OFF

switch.

3. For continuous operation, slide the

switch toward the front of the tool and

press the forward part of the switch

inward.

4. To stop the tool while operating in continuous mode, press the

rear part of the switch and release.

NOTE: To reduce unexpected tool movement, do not switch the

tool on or off while under load conditions.

CAUTION: Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come

to a complete stop before laying the tool down.

CAUTION: Allow the tool to reach full speed before touching

tool to the work surface. Lift the tool from the work surface before

turning the tool off.

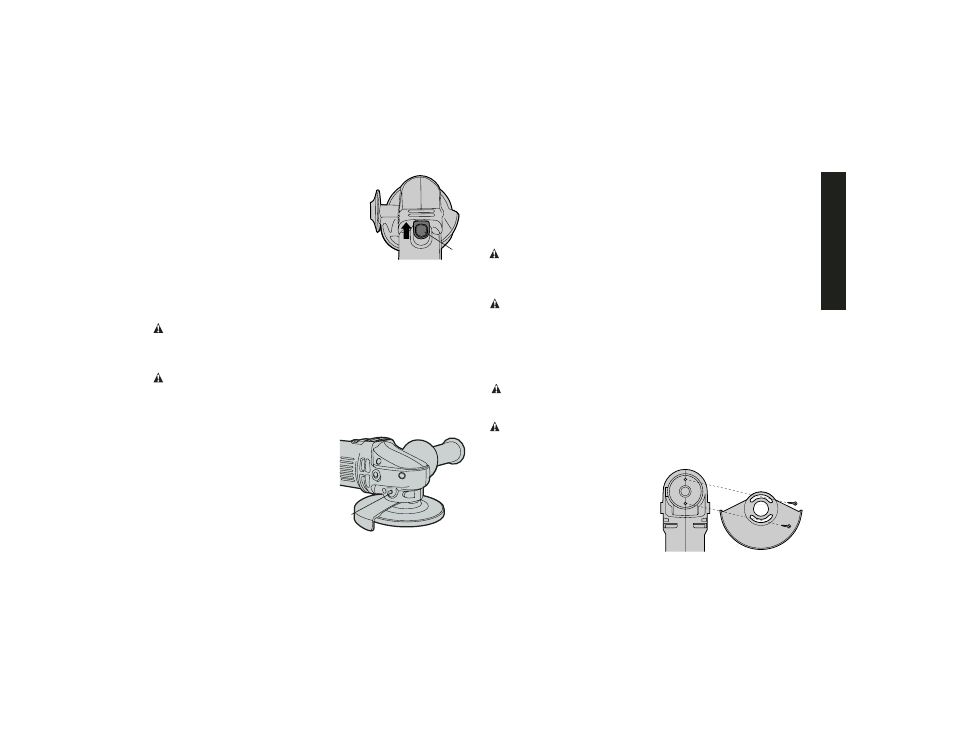

Spindle Lock

The spindle lock pin (E) is provided to

prevent the spindle from rotating when

installing or removing wheels. Operate

the spindle lock pin only when the tool

is turned off and unplugged from the

power supply. Do not engage the

spindle lock while the tool is operating

because damage to the tool will result

and attached accessory may spin off

possibly resulting in injury.

To engage the lock, depress the spindle lock button (E) and

rotate the spindle until you are unable to rotate the spindle further.

Mounting and Using Depressed Center

Grinding Wheels and Sanding Flap Discs

MOUNTING AND REMOVING GUARD

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or acces-

sories. Before reconnecting the tool, actuate and release

switch to ensure that the tool is off.

CAUTION: Guards must be used with all grinding wheels, sand-

ing flap discs, wire brushes, and wire wheels. The tool may be used

without a guard only when sanding with conventional sanding

discs. D

E

WALT model DW400 is provided with a guard intended for

use with depressed center wheels (Type 27) and hubbed grinding

wheels (Type 27). The same guard is designed for use with sanding

flap discs (Type 27 and 29) and wire cup brushes and wire wheels.

CAUTION: Type 1 Abrasive and Diamond Cut-Off Wheels may

not be used on this tool. A Type 1 Cut-Off Wheel Guard is not avail-

able for the DW400.

CAUTION: Proper guard must be re-installed for grinding wheel

applications after sanding applications are complete.

1. Align the openings on the guard with the holes on the grinder,

as shown.

2. With guard skirt facing away

from grinder, rotate the guard

into desired working position.

The guard should be posi-

tioned between the spindle

and the operator to provide

maximum operator protection.

E

A

English

7