Unvented natural gas log heater, Installation, Continued – Desa CGS2718N User Manual

Page 12

12

107067

UNVENTED NATURAL GAS LOG HEATER

CGS2718N, CGS3124N,

CLD3018NA, and CLD3924NTA

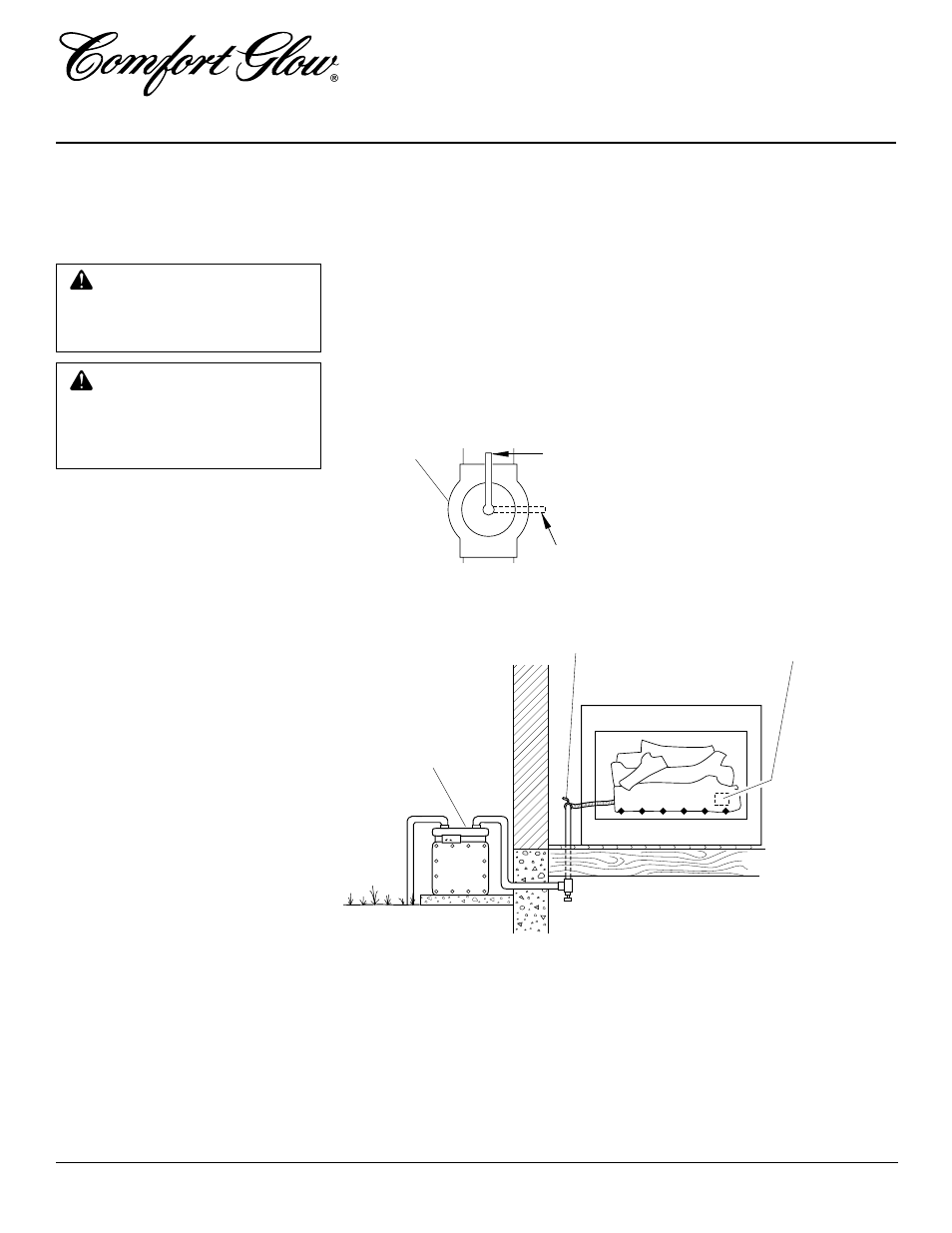

Figure 14 - Equipment Shutoff Valve

ON

POSITION

OFF

POSITION

Open

Closed

Equipment

Shutoff Valve

Figure 15 - Checking Gas Joints

Gas Meter

Equipment

Shutoff Valve

Control Valve Location

INSTALLATION

Continued

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

WARNING: Test all gas pip-

ing and connections for leaks

after installing or servicing. Cor-

rect all leaks at once.

CHECKING GAS

CONNECTIONS

Pressure Testing gas Supply

Piping system

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1.

Disconnect appliance with its appliance

main gas valve (control valve) and equip-

ment shutoff valve from gas supply pip-

ing system. Pressures in excess of 1/2 psig

will damage heater regulator.

2.

Cap off open end of gas pipe where

equipment shutoff valve was con-

nected.

3.

Pressurize supply piping system by ei-

ther using compressed air or opening

main gas valve located on or near gas

meter.

4.

Check all joints of gas supply piping

system. Apply mixture of liquid soap

and water to gas joints. Bubbles form-

ing show a leak.

5.

Correct all leaks at once.

6.

Reconnect heater and equipment

shutoff valve to gas supply. Check re-

connected fittings for leaks.

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1.

Close equipment shutoff valve (see Fig-

ure 14).

2.

Pressurize supply piping system by ei-

ther using compressed air or opening

main gas valve located on or near gas

meter.

3.

Check all joints from gas meter to

equipment shutoff valve (see Figure

15). Apply mixture of liquid soap and

water to gas joints. Bubbles forming

show a leak.

4.

Correct all leaks at once.

Pressure Testing Heater Gas

Connections

1.

Open equipment shutoff valve (see Fig-

ure 14).

2.

Open main gas valve located on or near

gas meter.

3.

Make sure control knob of heater is in

the OFF position.

4.

Check all joints from equipment shutoff

valve to control valve (see Figure 15).

Apply mixture of liquid soap and wa-

ter to gas joints. Bubbles forming show

a leak.

5.

Correct all leaks at once.

6.

Light heater (see Operating Heater,

pages 15 and 16 [manually-controlled

models] or pages 16 and 17 [thermo-

statically-controlled models]). Check

all other internal joints for leaks.

7.

Turn off heater (see To Turn Off Gas to

Appliance, page 16 [manually-con-

trolled models] or page 17 [thermostati-

cally-controlled models]).