Overload protection, Raising and lowering spindle, Fence adjustments – Delta 902118 43-505 User Manual

Page 9

9

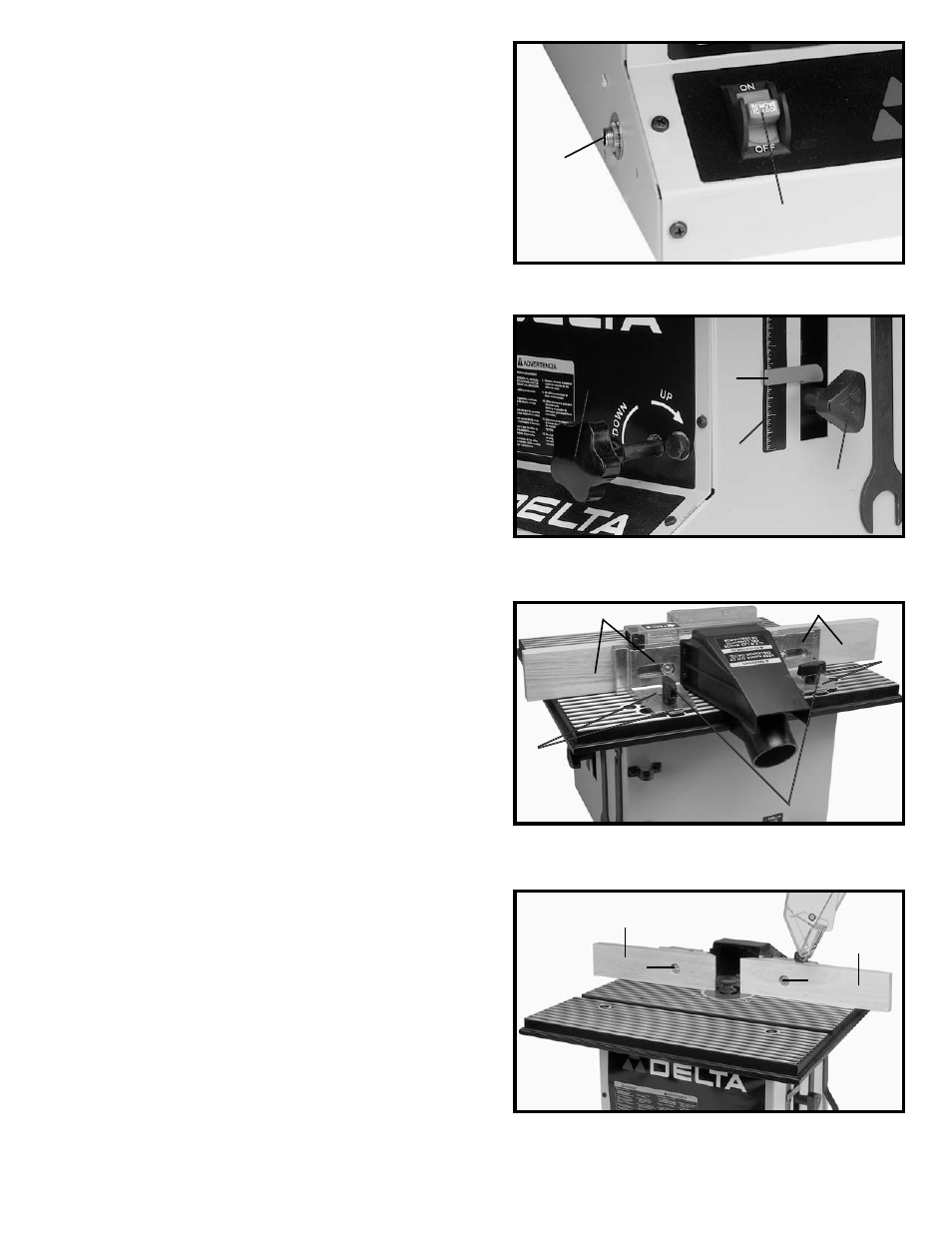

OVERLOAD PROTECTION

The Router/Shaper is equipped with overload protection.

If the motor shuts off, or fails to start due to overloading

(cutting stock too fast; using dull bits and cutters; using

the machine beyond its capacity or at low voltage, etc.),

TURN THE SWITCH (A) FIG. 16, TO THE “OFF”

POSITION. Let the motor cool three to five minutes and

push the overload reset button (C) which will reset the

overload device. The machine can then be turned on

again in the usual manner.

RAISING AND

LOWERING SPINDLE

To raise the spindle, loosen lock knob (A) Fig. 17, and

turn the elevation knob (B) clockwise. When the spindle

is at the desired height, tighten lock knob (A).

To lower the spindle, loosen lock knob (A) Fig. 17, and

turn elevation knob (B) counterclockwise. NOTE: Final

height setting of the cutter should always be from the

bottom to the up position. Always tighten lock knob (A)

after adjusting spindle height.

The Router/Shaper is equipped with a spindle height

adjustment scale (C) Fig. 17, and spindle height indicator

(D). The spindle height indicator moves up or down as

the spindle is raised or lowered.

Fig. 16

Fig. 17

A

C

FENCE ADJUSTMENTS

DISCONNECT MACHINE FROM POWER SOURCE.

Either half of the two-piece fence assembly (A) Fig. 18,

can be moved independently. To adjust each fence half,

loosen lock knob (B) and move fence half (A) to the

desired position depending on the work being

performed. Then tighten lock knob (B).

In order to do accurate work, both wooden fence halves

must be parallel with each other.

To check and adjust, move both fence halves in or out

until they are in line with each other. Using a straight

edge check to see if both fence halves are parallel with

each other the complete length of the fences. If an

adjustment is necessary, loosen four socket head cap

screws (C) Fig. 18, located on the fence bracket casting

directly in front of and in back of lock knobs (B) Fig. 18,

and adjust the fences accordingly. Then tighten the four

screws.

To adjust each wooden fence half (C) Fig. 19, for side to

side movement, loosen screw (D) and move wooden

fence (C) as needed. IMPORTANT: Each wooden fence

half (C) should be adjusted as close to the cutter as

possible, without touching. Once adjustments are made,

retighten screw (D).

Fig. 18

Fig. 19

A

A

B

D

D

C

C

A

B

C

D

C

C