Fig 6 fig 7 fig 8 fig 9 – Dillon Hunting Equipment User Manual

Page 3

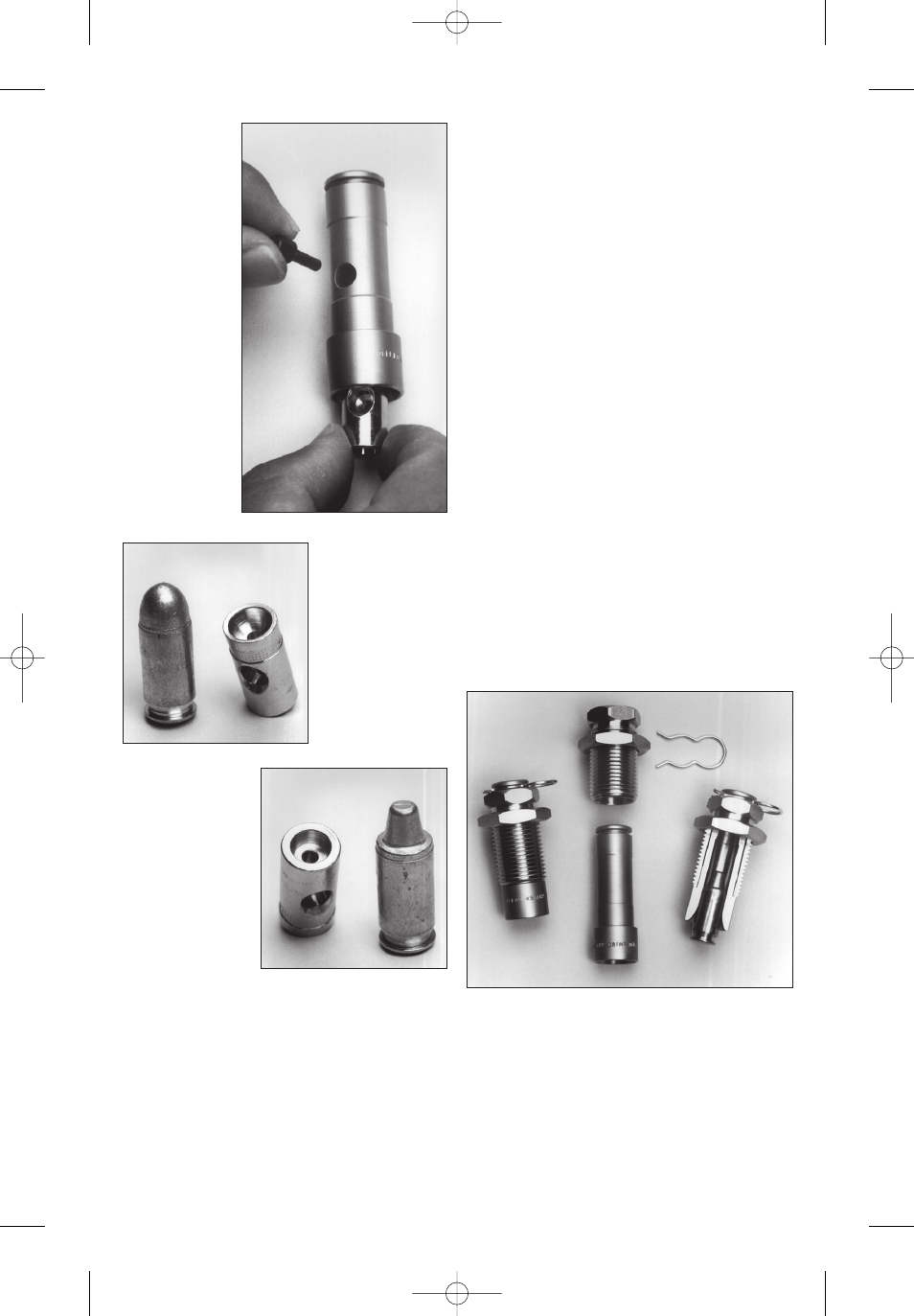

Fig 6. The

double-ended

seating stem

can then be

removed for

cleaning or

changing by

pushing out

the black cross

pin. Note that

the seat stem

is doubled

ended and can

be reversed to

match the

shape of your

bullet.

Figs 7 & 8.

Choose the

seating stem

which best fits

your bullet.

Fig 7 is the round

nose seating stem

and Fig 8 is the

semi-wadcutter

seating stem.

When the

desired configu-

ration is found

push the stem

back into the

insert and

replace the cross

pin. Reinsert the

seating insert

into the die

body. Replace

the clip and pro-

ceed.

Adjustment.

Place a sized

and belled case

into the seating

station of the

shellplate.

Next place a bullet on the mouth of the

case and cycle the handle down. Screw the

die down until it makes contact with the

bullet. Raise the handle a small amount and

screw the die down 1/2 turn. Cycle the han-

dle down and raise it to the top. Remove the

case with the partially seated bullet and

measure the overall length with dial

calipers.

Compare the length to that suggested in

your loading manual. If the OAL is too long

turn the seating die down in 1/8 turn incre-

ments and cycle the handle again.

Repeat the above process until the proper

seating depth is achieved.

Note: One full turn of the die is approxi-

mately 0.070 of an inch. As you get closer

to your desired length do not turn the die

down in more than 1/8 turn increments.

When the desired OAL has been achieved

snug the lock ring while the cartridge is in

the die.

Crimp adjustment. Place a belled case

with a seated bullet into the crimping station

of the shellplate and, with the die out of the

toolhead, cycle the handle down. Leave the

handle down and start the die into the tool-

head. Screw the die down until it contacts

the case.

Now, raise the handle (to pull the car-

tridge part way out of the die), screw the die

down 1/8 of a turn and then lower the han-

dle again. Remove the case from the die and

check for the proper crimp. (Note: refer to a

loading manual for proper crimp dimen-

sion.)

If your case is not crimped enough,

place the cartridge back into the shellplate

and repeat your adjustments in 1/8 turn

increments until you achieve the proper

crimp.

Fig 9. Crimp die assembly. On the left the

completed assembly is shown before screw-

ing it into the toolhead.

IMPORTANT Now is the time to try this

round to see that it fits the barrel or cylinder

of your gun. Also, if you’re loading for a

semi-auto, it’s a good idea to load 10-20

rounds and fire them. It’s depressing to load

a thousand rounds and then find out they

won’t function the action of your gun.

Fig 6

Fig 7

Fig 8

Fig 9

Dillon Die Instructions, May 2007 5/22/07 1:47 PM Page 3