REFCO RL-8 User Manual

Page 4

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

Industriestrasse 11

Telefax

+41 41 919 72 83

6285 Hitzkirch - Switzerland

[email protected] www.refco.ch

REFCO Manufacturing Ltd.

Telefon

+41 41 919 72 82

Industriestrasse 11

Telefax

+41 41 919 72 83

6285 Hitzkirch - Switzerland

[email protected] www.refco.ch

Change of oil

• Run the pump until operating temperature has been reached. Turn the

pump of and disconnect from mains.

• Unscrew the oil mist filter (Pos. 19)

• Drain oil through drain plug (RL-4/RL-8 Pos. 23) or through opening for

oil mist filter (model RL-2 does not have an oil drainage plug and the

oil must be drained through opening of oil mist filter).

• Connect pump to the mains again and turn on. Let the pump run for

10-15 seconds with open intake port in order to drain oil residue in the

pump head.

• Turn the pump off and disconnect from the mains.

• Drain possible oil residue.

• Remount oil drain plug (Pos. 23).

• Refill with oil to half level of sight glass.

• Refit oil mist filter (Pos. 19). Let the pump run for a few seconds.

If the oil has been strongly contaminated the oil change procedure

must be repeated after a run time of 30 minutes in order to assure

that all waste particles inside the pump have been washed out with

the oil.

In order to achieve best performance with the REFCO vacuum pumps

only use REFCO oils DV-44, DV-45, DV-46, DV-48 or REFCO ester oil.

Waste oil must be disposed of according to the rules and

regulations which apply in the country of use of the pump.

Further service work than oil change has to be executed by a specialised

company.

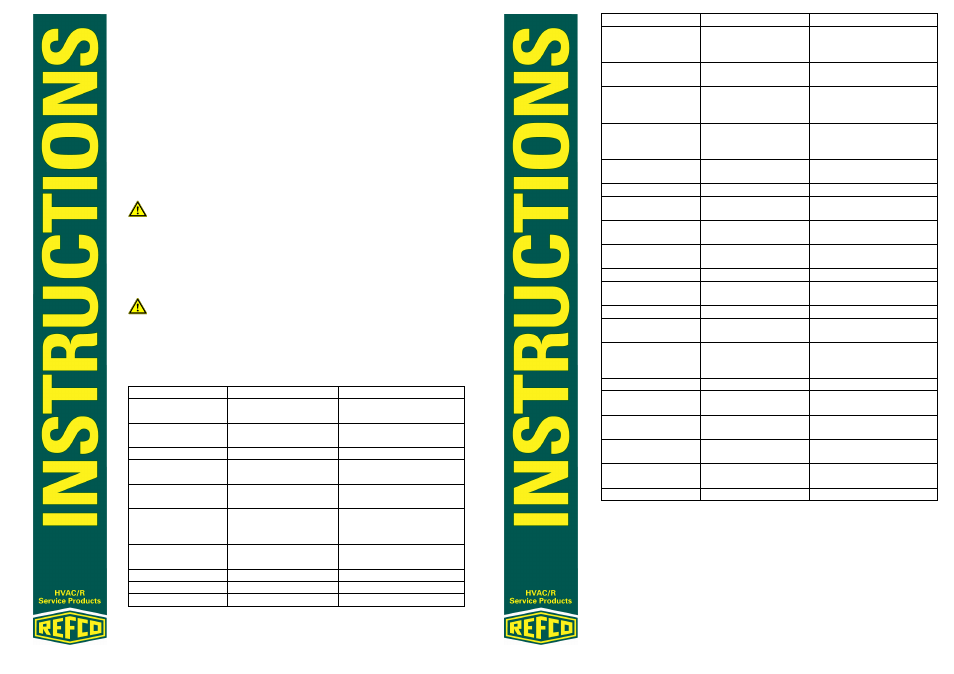

Trouble shooting

Condition

Possible problem

Solution

Pump does not

run on full speed

Oil temperature

too low

Put the pump in warmer

environment/room

Unsuitable oil – too

thick

Change with REFCO oil

Pump dirty

Change oil

Motor winding

defective

Call customer service

The connection

cable is too long

Use a shorter

connection cable

Supply voltage is

too low

Pump is designed to

work at +/- 10% of the

supply voltage

Motor does not

start at all

Defective capacitor

Change capacitor

Call customer service

Switch defective

Replace switch

Motor too hot

Let it cool down

Cable defective

Replace cable

Condition

Possible problem

Solution

Motor drones but

does not run,

Pump locked up

Oil heavily

contaminated

Change pump head

Call customer service

Motor runs ⇒ no

performance

Broken clutch pin

Call customer service

Oil spillage on oil

mist filter

Pump overfilled with

oil

Adjust oil to half level of

sight glass, drain

additional oil

Extensive oil mist

from oil mist filter

Pump pressure =

atmospheric

pressure

Oil mist will disappear as

soon as a certain vacuum

has been reached

Oil not visible in

sight glass

Not enough oil in

pump

Top up with oil

Oil cloudy or dark

Contaminated oil

Change oil

Not enough

vacuum

Gas ballast open

Close gas ballast valve

Call customer service

Loose cap on intake

port

Screw the cap on tightly

O-ring in the intake

port cap is faulty

Replace O-ring

Oil level too low

Refill oil

Oil is muddy (cloudy)

or contaminated

Change oil

Pipe leaking

Check pipe, seal it

Pump is worn out

after lengthy use

Repair or replace pump

Motor noisy

Bearings worn out

Defective fan

impeller

Call customer service

Change impeller

Defective ventilator

Replace ventilator

Pump loses oil

Leaking gasket of oil

box

Change O-ring

Oil draining screw

leaking

Replace oil draining

screw

Leaking gasket of

sight glass

Change sight glass

Leaking gaskets box

screws

Change gaskets of oil of

screws

Leaking shaft seals

Call customer service

Warranty

REFCO grants a 24 month warranty period. Damage caused due to

improper use, lack of service as described in this manual, use of the

pump for other applications as the designated ones, use of unsuitable

vacuum pump oil or opening and dismantling the pump during warranty

period by the user will lead to loss of warranty. For repairs during the

warranty period the vacuum pump must be returned to the seller at

owners cost.