0 operation, 0 troubleshooting – NIBCO Bronze, Globe and Angle Valves 1/ to Class 175 WWP User Manual

Page 6

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

6

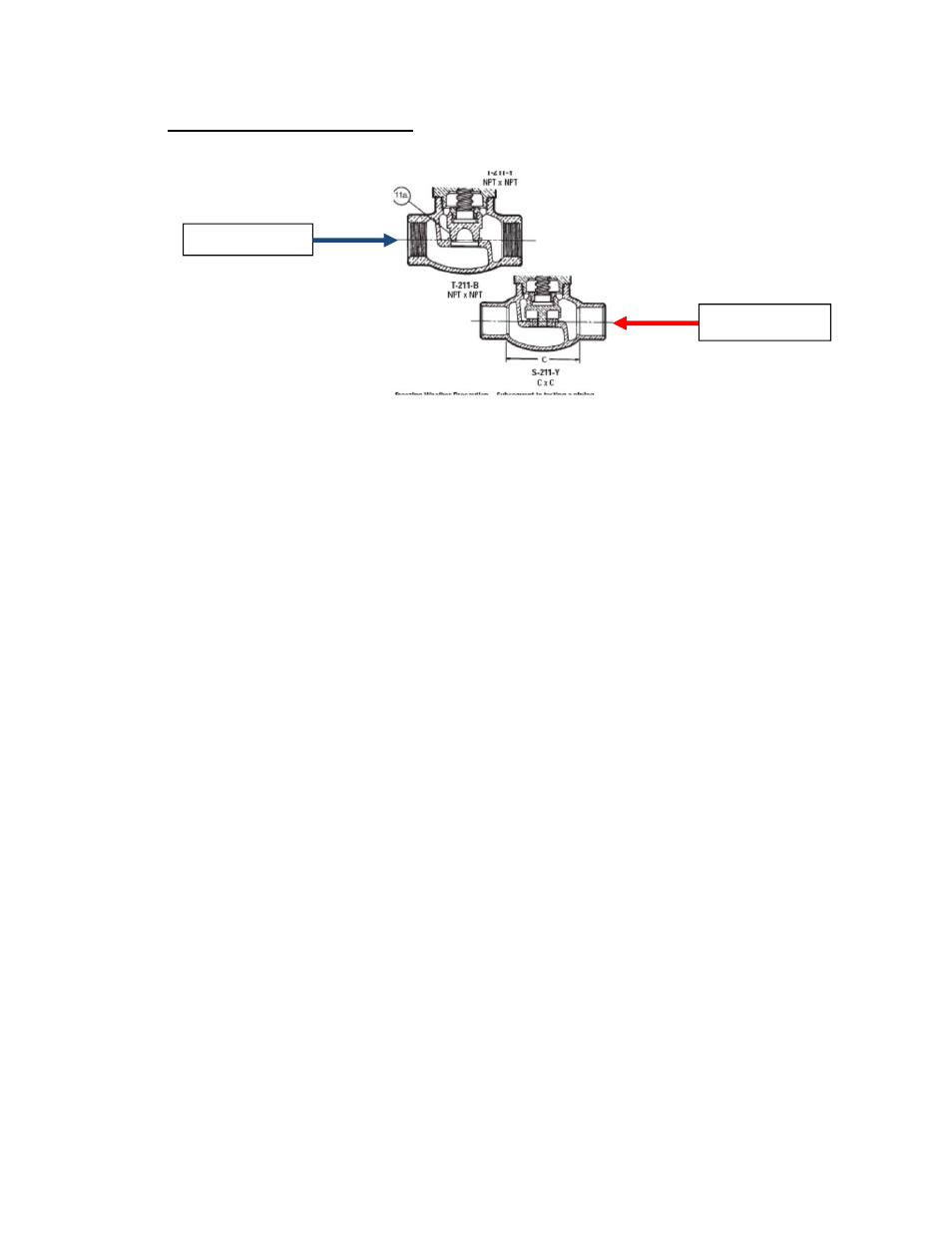

For water service applications: The flow should enter the valve so that it pushes up

from underneath the seat disc. In other words, water flow should arrive from under the

seat disc and flow smoothly out of the valve over the seat.

After the valve has been installed, the valve should be tested to make sure that it opens

and closes easily and that the bonnet joints or pipe joints are not leaking.

3.0 OPERATION

Globe valves are generally installed to be used for throttling purposes. They normally

have high flow restriction and are not recommended where small pressure drops are

mandatory.

A globe or angle pattern valve must be sized for the specific application, this is very

important. When sizing a globe valve for throttling in either the straight or angle pattern it

is important to avoid tight throttling. A valve sized too large that is tightly throttled can

increase the velocity of the fluid to the point that it can cut (wire draw) through the seat

and/or disc. When the valve is then shut off, it will leak badly.

4.0 TROUBLESHOOTING

4.1

LEAKAGE THROUGH THE BONNET JOINT

If the bonnet joint leaks, the valve should be isolated and depressurized. The bonnet

should be removed according to instructions in Section 5. The seating surfaces of the

bonnet and body should be closely inspected. If there is any scratch or mark on these

surfaces then it is necessary that a flat surface sanding plate of 400 grit be used on the

body to remove all the scratches. After the scratches are removed, blueing should be

applied to a flat plate and put onto the bonnet surface. If there are no high spots on the

bonnet surface, then it is prepared for reassembly. If there are scratches or nicks that

are evident on the bonnet surface, it is necessary that it be indicated in a lathe and a

very slight cut taken off of the bonnet sealing surface at an angle of approximately 2 1/2”

tapered outward with a very fine 32 RMS finish. The two surfaces then can be

reassembled using procedures in Section 2.

4.2

LEAKAGE THROUGH THE STUFFING BOX

Leakage through the stuffing box packing may be stopped by tightening the packing nut.

Water Flow

Steam Flow