NIBCO Check Valve Automatic Stop F869B User Manual

Page 11

NIBCO Technical Services • Phone: 1.888.446.4224 • Fax: 1.888.336.4224

11

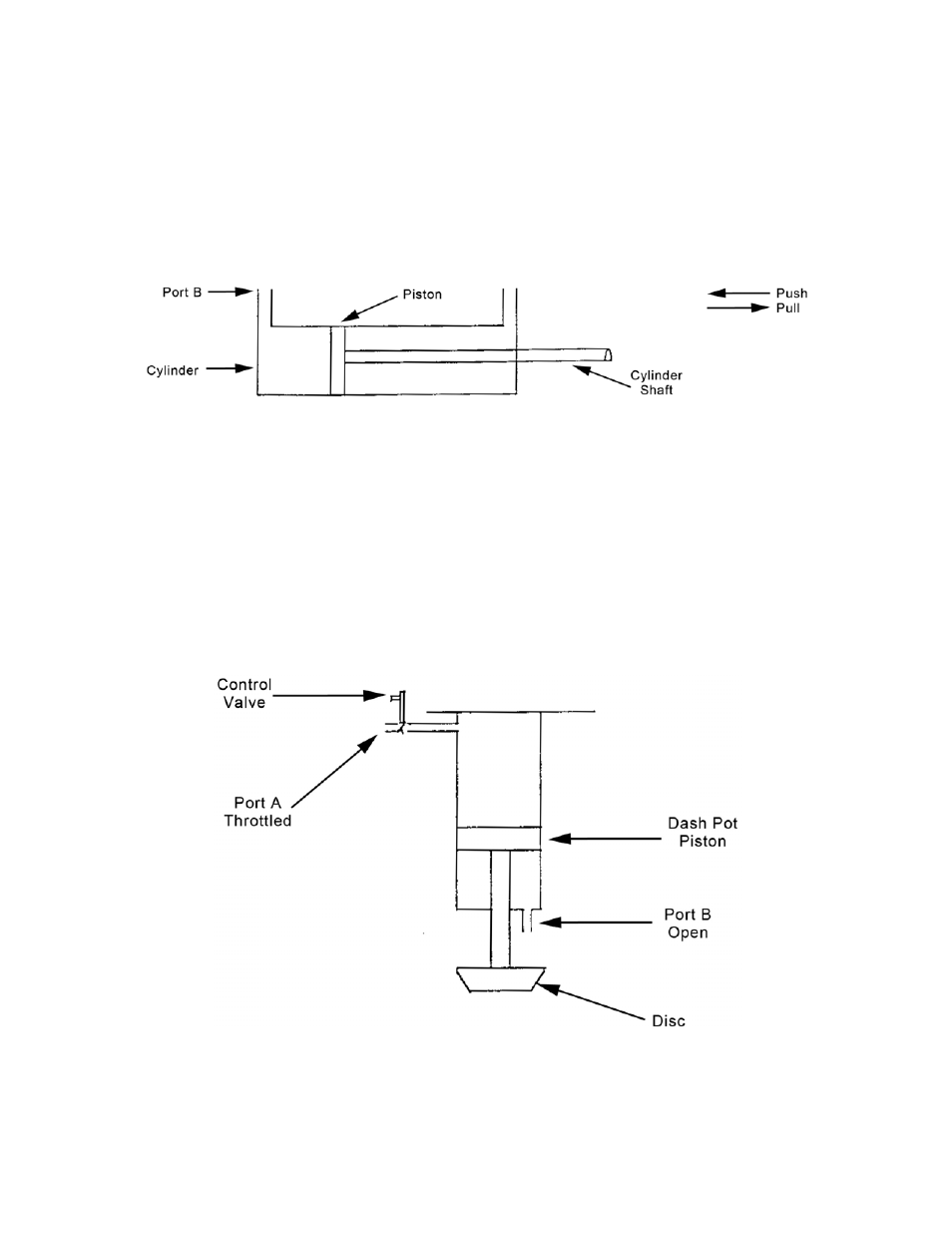

Finally, we come to the questions – How is this done? How does the dashpot work? How is the

adjustment made?

The dashpot is the same in principle as a shock absorber on an automobile. It does not prevent,

but rather controls the rate of movement. The dashpot must have fluid to displace. In the case of

the stop-check, this fluid is the fluid within the piping system, namely steam. All dashpots are

very similar to an air cylinder.

If one tries to push the disc-piston down in the cylinder, air will come out of the bottom of the

cylinder into Port A. Pushing the disc-piston up in the cylinder will cause air to be pushed

through Port A. Now if a throttle (dampener) valve is put on Port A and throttled very closely, the

same amount of force applied to push down the disc-piston will allow a much reduced rate of air

movement. This creates a partial vacuum in the cylinder. This reduces the rate of descent much

as ketsup is held in the bottom by a partial vacuum. So, when the disc bottoms out there will

only be a small click heard instead of a loud bang. The rate of travel will be controlled by the

dampener control valve being opened or closed.

We have now developed the principle on which the NIBCO stop-check valve was designed, only

now we add the principle of gravity and keep the air cylinder in the vertical position and add a

disc to have the following diagram.

Now note that Port B is merely a drilled hole at the bottom of the dashpot, which allows the

steam to enter and exit freely. Also, it serves to drain any resultant condensation. Port A, you

will note, has a control valve which can be throttled to allow steam to enter the chamber above

the piston, either rapidly for quick descent or slowly for a slow descent. This is a function of the