Lp9.9 operators manual final en 9, Installation, Lehr – LEHR 9.9 HP 4-STROKE User Manual

Page 9

LEHR

|

ALL RIGHTS RESERVED 2013-2014

7

INSTALLATION

INSTALLATION

Incorrect engine height or obstructions to smooth water flow in front of the propeller can cause propeller

cavitation while the boat is cruising. Cavitation occurs when the engine speeds up momentarily and suddenly

slows as the propeller engages the water. Severe engine damage may result if the motor is operated

continuously while cavitating. During water testing check the buoyancy of the boat, at rest, with its maximum

load. Check that the static water level on the exhaust housing is low enough to prevent water entry in to the

power head, when water rises due to waves when the outboard is not running.

MOUNTING THE OUTBOARD MOTOR

• Overpowering a boat could cause severe instability. Do not install an outboard motor with more horsepower

than the maximum rating on the capacity plate of the boat. If the boat does not have a capacity plate,

consult the boat manufacturer.

• This section is intended as reference only. It is not possible to provide complete instructions for every

possible boat and motor combination. Proper mounting depends in part on experience and the specific boat

and motor combination. Improper mounting of the outboard motor could result in hazardous conditions, or

poor handling, loss of control, or boat damage.

• Your dealer or other person experienced in proper out board motor mountings should show you how to

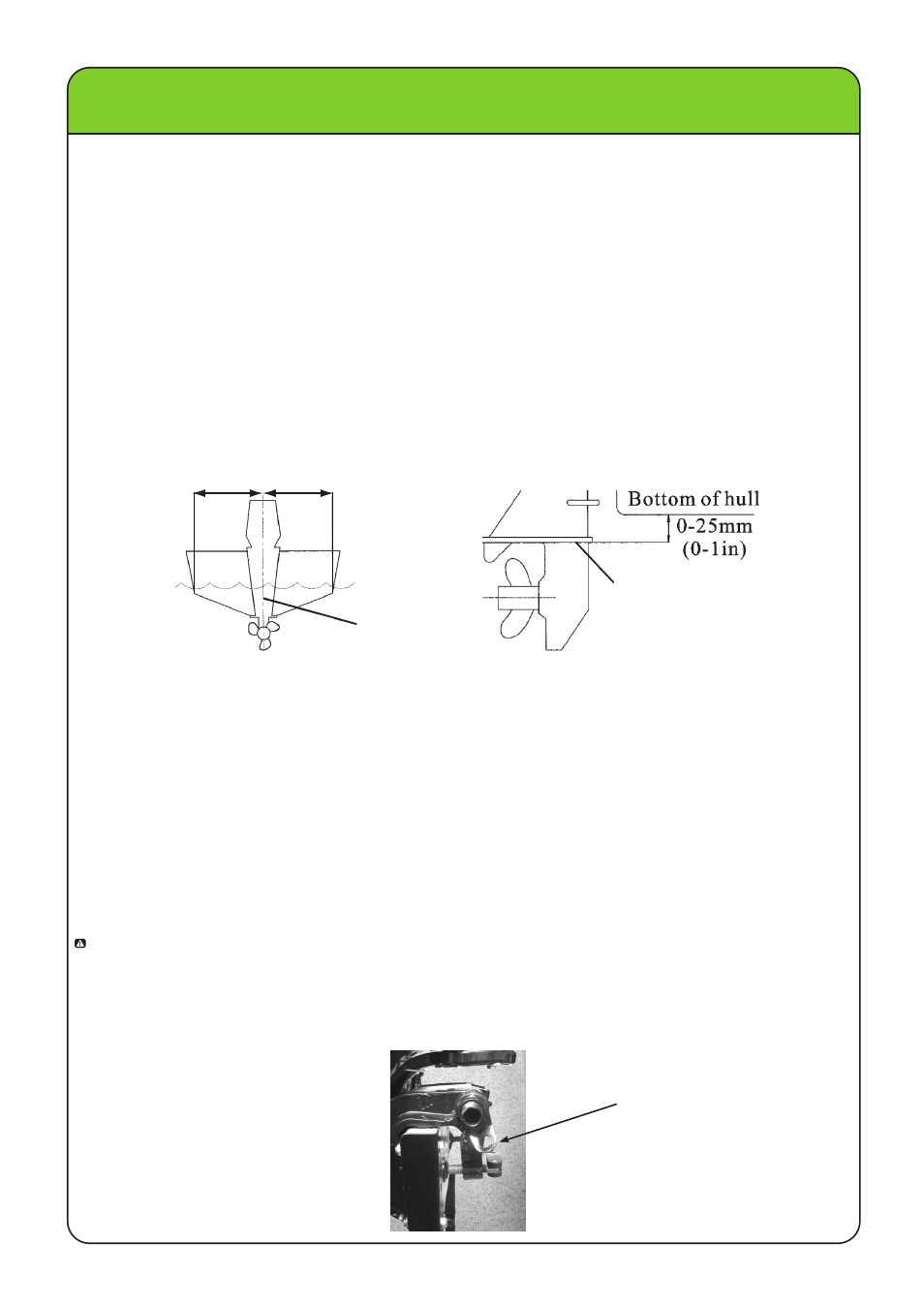

mount your motor. Mount the outboard motor on the center line (keel line) of the boat, and ensure that the

boat itself is well balanced. Otherwise the boat will be hard to steer. For boats without a keel or which are

asymmetrical, consult your dealer.

MOUNTING HEIGHT

To run your boat at best efficiency, the water resistance (drag) of the boat and outboard motor must be

made as little as possible. The mounting height of the outboard motor greatly affects the water resistance.

If the mounting height is too high, cavitation tends to occur, thus reducing the propulsion, and if the propeller

tips cut the air, the engine speed will rise abnormally and cause the engine to over heat. If the mounting

height is too low, the water resistance will increase and thereby reduce engine efficiency. Mount the

outboard motor so that the anti-cavitation plate is between the bottom of the boat and a level 25mm (1in.)

below it.

The optimum mounting height of the outboard motor is affected by the boat and motor combination and the

desired use. Test runs at different heights can help determine the optimum mounting height. Consult your

boat manufacturer for further information on determining the proper mounting height.

CLAMPING THE OUTBOARD MOTOR

1. Place the outboard motor on the transom so that it is positioned as close to the center as possible. Tighten

the transom clamp screws evenly and securely. Occasionally check the clamp screws for tightness during

operation of the outboard motor because they could become loose due to engine vibration.

WARNING: Loose clamp screws could allow the outboard motor to fall off or move on the transom. This could

cause loss of control and serious injury. Make sure the transom screws are tightened securely.

Occasionally check the screws for tightness during operation.

2. If an engine restraint cable or chain attachment is equipped on your boat, the cable or chain should be

used. Attach one end of the engine restraint cable attachment to the engine clamp and the other to a

secure mounting point on the boat. Otherwise the engine could be completely lost if it accidentally falls

off the transom.

CENTER LINE

(KEEL LINE)

a

a

ANTI-CAVITATION PLATE

ATTACH ONE END OF THE RESTRAINT

CABLE THROUGH THIS CLAMP MOUNT

AND ONE END SECURELY ON THE BOAT