Chapter 2: prerequisites – Labconco XPert Weigh Boxes 5220331 User Manual

Page 10

Chapter 2: Prerequisites

Product Service 1-800-522-7658

6

Additionally, the motorized impeller can also be used in a full recirculation

mode providing the operator with some control of the atmosphere chemistry

within the glove box. See Chapter 7 for the Recirculation Conversion Kit.

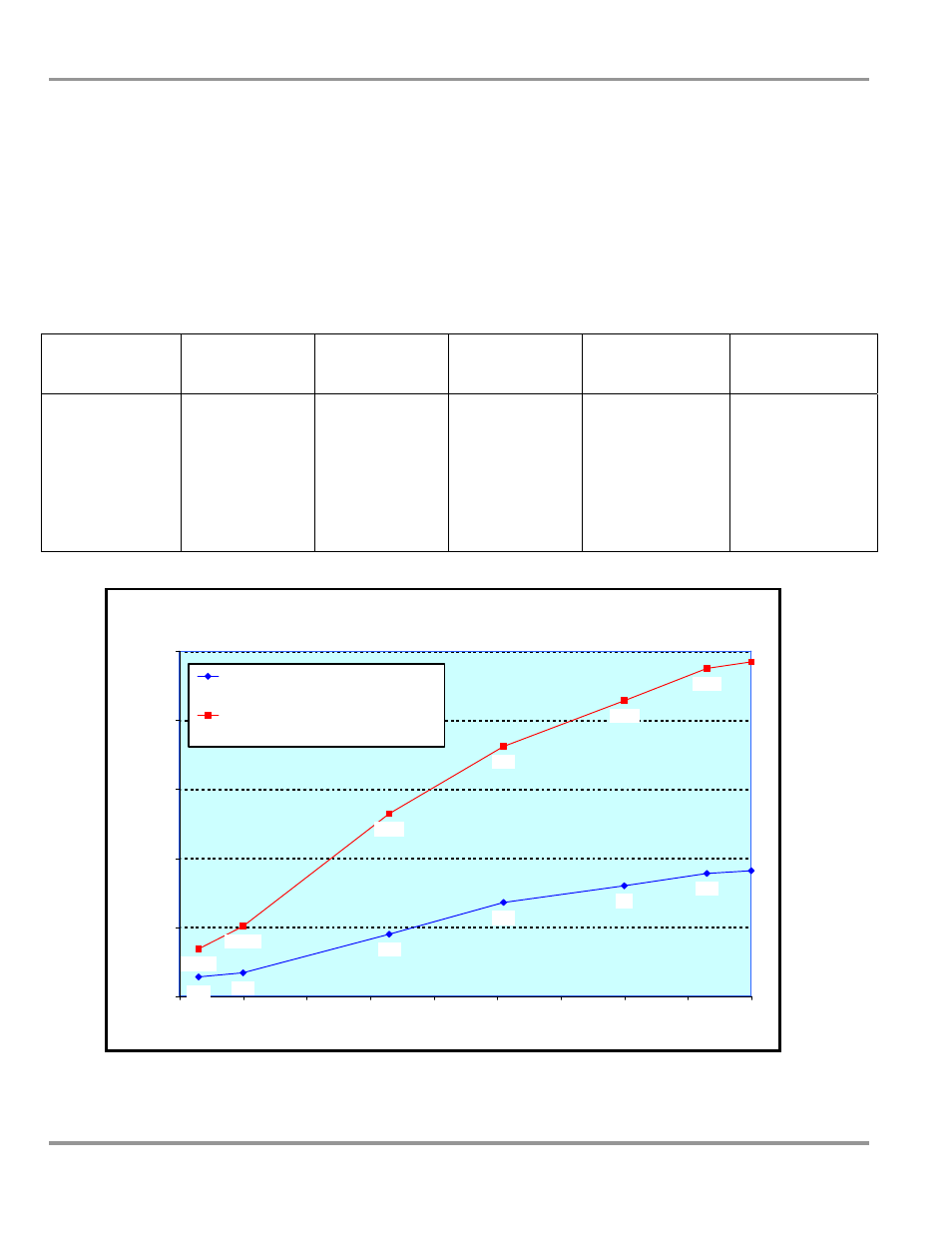

The airflow chart below represents typical operational data including air

changes per minute, exhaust volume, noise levels, main chamber static

pressures, and total system static pressures measured at the blower intake

(suction side). Exhaust volumes are reduced by 17% for products operating

on 100V, 60 Hz and reduced 34% for 100V, 50 Hz products.

Dial Setting

Air Changes

per Minute

(acm)

Exhaust

Volume

(CFM)

Noise Pressure

dB (A)

Static Pressure

Inside Glove Box

(inches of water)

Total System

Static Pressure

(inches of water)

Min. Dial

20 Dial

40 Dial

50 Dial

60 Dial

80 Dial

Max. 100 Dial

Dial OFF

1

1.5

3.3

4.7

6.2

7.2

7.7

0

13

20

43

61

80

93

100

0

44

48

48

65

68

70

71

37

.14

.17

.45

.68

.80

.89

.91

0

.34

.51

1.32

1.81

2.14

2.38

2.42

0

XPERT WEIGH BOX

Static Pressure Test Results

0.14

0.17

0.45

0.68

0.8

0.89

0.91

0.3435

0.5072

1.323

1.81

2.141

2.375

2.422

0

0.5

1

1.5

2

2.5

10

20

30

40

50

60

70

80

90

100

Airflow Volume

(Cubic Feet per Minute)

Ne

ga

ti

ve St

ati

c

Pres

su

re

(I

nc

he

s of

Wa

te

r Colum

n

)

Static Pressure Inside Glove Box

Total Static Pressure at Blower

Intake (Suction Side)