Elenco Metal Detector User Manual

Page 6

-5-

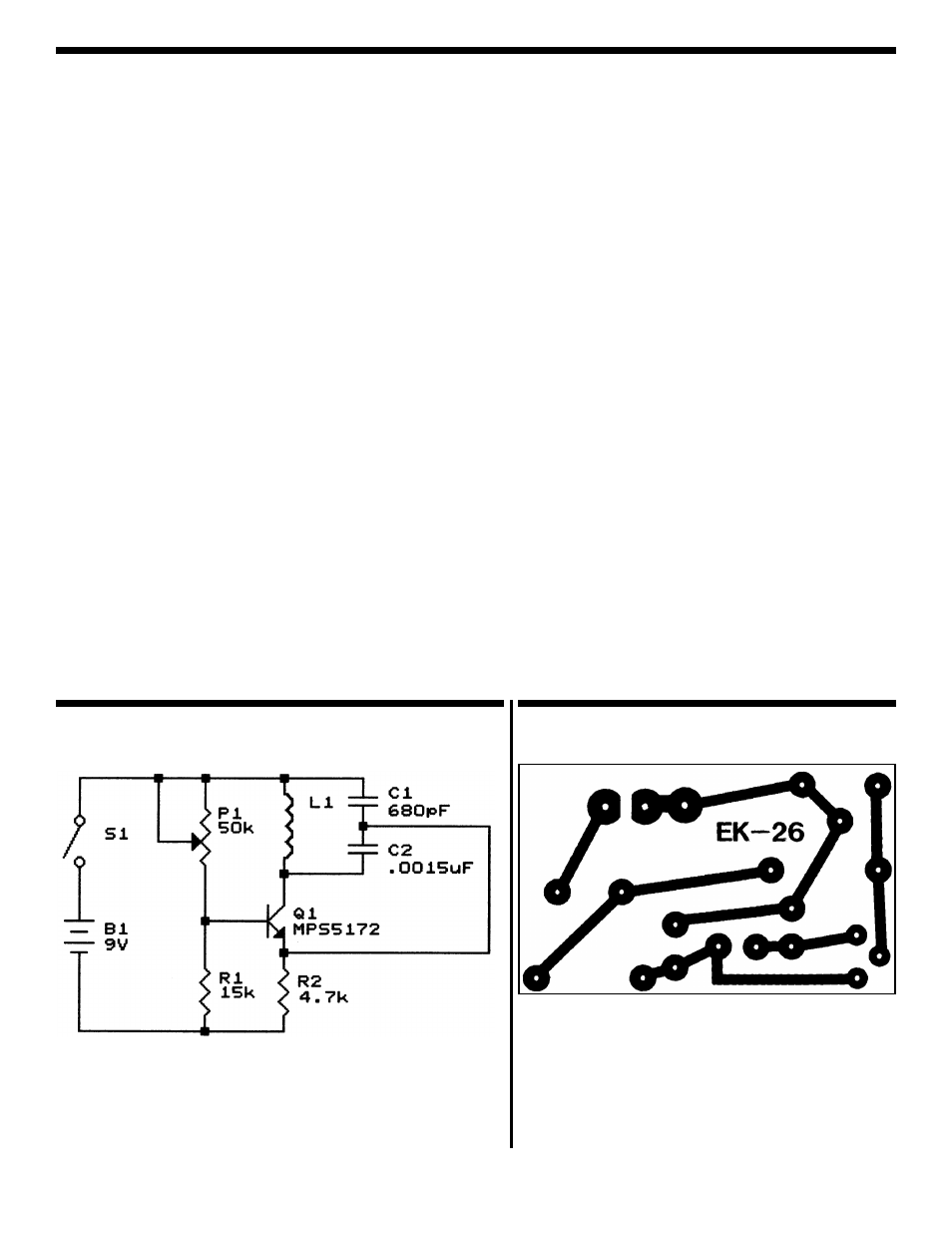

SCHEMATIC DIAGRAM

PC BOARD FOIL SIDE

TROUBLESHOOTING

Contact ELENCO

®

if you have any problems. DO NOT contact your place of purchase as they will not be able

to help you.

1. One of the most frequently occurring problems is

poor solder connections.

a) Tug slightly on all parts to make sure that

they are indeed soldered.

b) All solder connections should be shiny.

Resolder any that are not.

c) Solder should flow into a smooth puddle

rather than a round ball. Resolder any

connection that has formed into a ball.

d) Have any solder bridges formed? A solder

bridge may occur if you accidentally touch

an adjacent foil by using too much solder or

by dragging the soldering iron across

adjacent foils. Break the bridge with your

soldering iron.

2. Be sure that all components have been mounted

in their correct places.

a) Use a fresh 9V battery.

b) Be sure that the coil is soldered properly.

The two ends of the wire should be clear of

insulation, so that the solder can make good

contact with the wire.

c) Your most likely problem will be tuning the

metal detector oscillator to the radio. Start at

around the 1,000kHz spot on the radio. Pick

a spot that is clear of radio stations. You

should hear only static. Rotate the

potentiometer P1 very slowly until the static

gets quiet. If you cannot quiet the radio, tune

the radio to a higher frequency, around

1,300kHz and try adjusting the poten-

tiometer again. If still no luck, try a lower

frequency, around 700kHz. You should be

able to find a spot when the metal detector

oscillator has an effect. Moving a piece of

metal around the coil should produce

changes in the sound from the radio.