Dunkirk Q90-200 Series II User Manual

Page 6

6

Locating The Boiler

1.

Select level location, central to piping systems served

and close to vent and air intake terminals as possible.

2.

Manufacture recommended accessibility clearances, if

more stringent (i.e. larger clearances) than required

fire protection clearances, must be used for boiler

installation. Accessibility clearances may be achieved

with use of removable walls or partitions.

3.

Combustible clearances shown in Table 4 indicate

required clearances per CSA listing. Minimum 1”

(25 mm) clearance must be maintained between

combustible construction and each of the right, top

and back surfaces of boiler. Minimum 8” (203 mm)

clearance is required on left side, to allow room for inlet

air pipe. 18” (457 mm) clearance must be maintained

at front where passage is required for cleaning or

servicing, inspection or replacement of any parts

that normally require such attention. Allow 24” (610

mm) at front and left side and 8” (203 mm) at top for

servicing. No combustible clearances are required to

venting or combustion air intake piping.

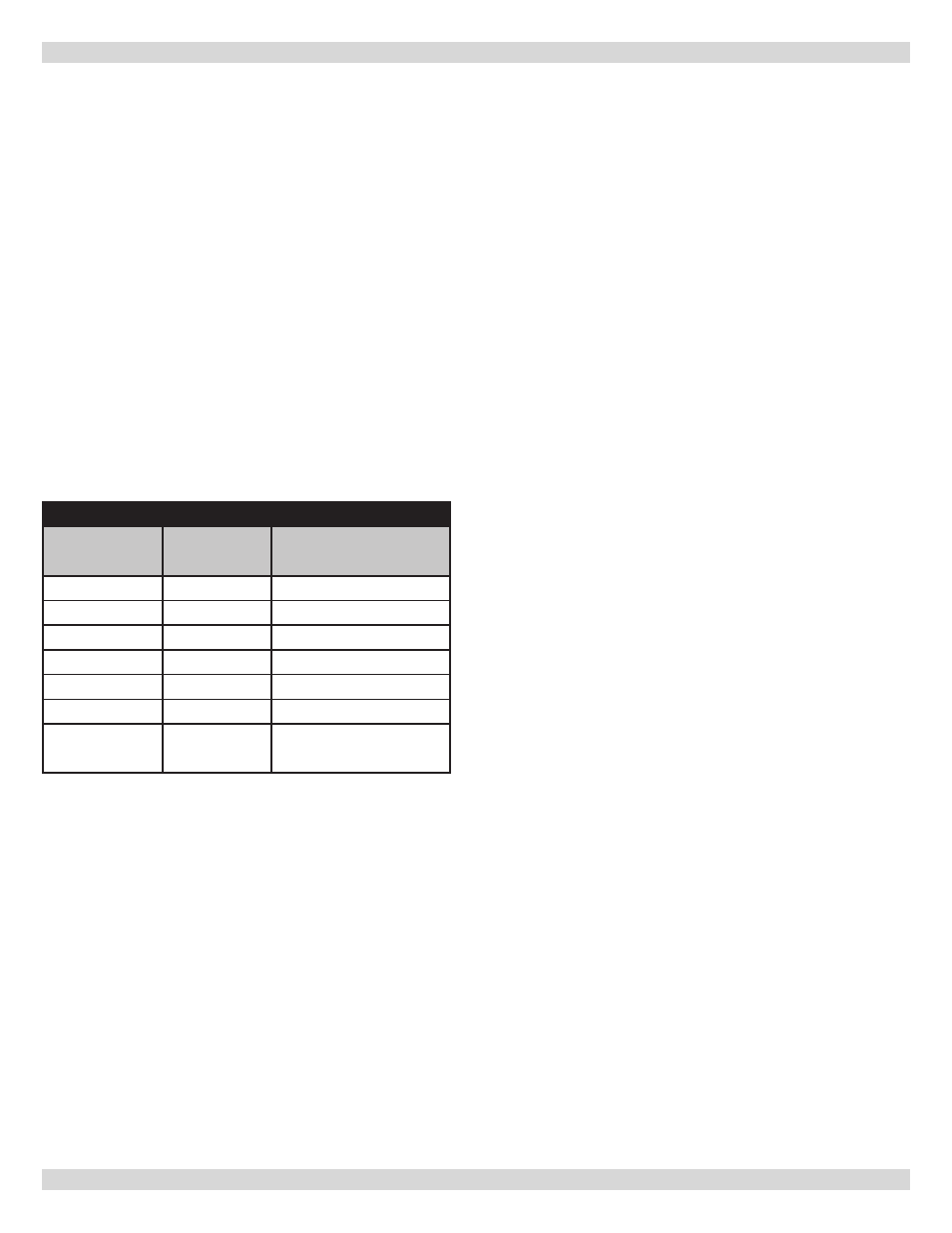

Table 4 - BOILER CLEARANCES

Unit

Combustible

Clearance

Accessibility, Cleaning,

and Servicing

Top

1” (25 mm)

8” (203 mm)

Left Side

8” (203 mm)

24” (610 mm)

Right Side

1” (25 mm)

-

Base

1” (25 mm)

-

Front

0” (0 mm)

24” (610 mm)

Back

1” (25 mm)

-

Intake/Vent

Piping

0” (0 mm)

-

All distances measured from boiler cabinet.

4.

Keep boiler area clean of debris and free of flammable

and combustible materials, liquids and vapors.

5.

Install equipment in location which facilitates operation

of venting and combustion air intake piping systems as

described in this manual.

6.

Advise owner to keep venting and combustion air

intake passages free of obstructions. Both venting

and combustion air intake piping systems connected

to outdoors must permit flow through piping systems

without restrictions for boiler to operate.

7.

Boiler shall be installed such that automatic gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during operation and

service (circulator replacement, condensate trap,

control replacement, etc.).

8.

Boiler must be located where ambient temperatures

(minimum possible room temperatures where boiler

is installed assuming boiler is not in operation and

therefore contributes no heat to space) are always

above freezing temperature.

9.

If boiler is not level condensate drain lines will not

function properly. Adjustable feet are located on boiler

to make up for minor surface irregularities or tilt.

10.

Wood frame or blocks may be used to raise boiler

to maintain drain pitch or to be above external

condensate pump reservoir.

11.

Provide means for condensate drainage.

3 - LOCATING THE BOILER

Removal Of Existing Boiler From Common Vent

System

When an existing boiler is removed from a common

venting system, the common venting system is likely to be

too large for proper venting of the appliances remaining

connected to it. At the time of removal of an existing boiler,

the following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remaining

connected to the common venting system are not in

operation.

1.

Seal any unused openings in the common venting

system.

2.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage

or restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

3.

In so far as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryer and any appliance not connected

to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhaust, so

they will operate at maximum speed. Do not operate a

summer exhaust fan. Close fire dampers.

4.

Place in operation appliance being inspected. Follow

lighting instructions. Adjust thermostat so appliances

operate continuously.

5.

Test for spillage at draft hood relief opening after 5

minutes of main burner operation. Use flame of match

or candle, or smoke from cigarette, cigar or pipe.