Suggested screen frame building instructions – Da-Lite Lace and Grommet Screen Surfaces User Manual

Page 4

4

Suggested Screen Frame Building Instructions

NOTE: Inside width and height of screen frame should be

12" greater than picture size or 7" greater than over-all size

(including the webbing).

Lumber – Redwood, Spruce, Pine, White Fir. Use 2" x 4" stock

for frames to hold screens 11' x 14' or under. Use 2" x 6" stock

for screens of larger sizes.

Cutting Lumber – 2" x 4" stock-Cut sides or vertical pieces

1' 8" longer than over-all vertical measurements of screen.

Cut top and bottom or horizontal pieces 1' 3" longer than

over-all horizontal width of screen. 2" x 6" stock-Cut vertical

pieces 2' longer than over-all vertical measurements of screen.

Cut top and bottom of horizontal pieces 1' 6" longer than

over-all horizontal width of screen.

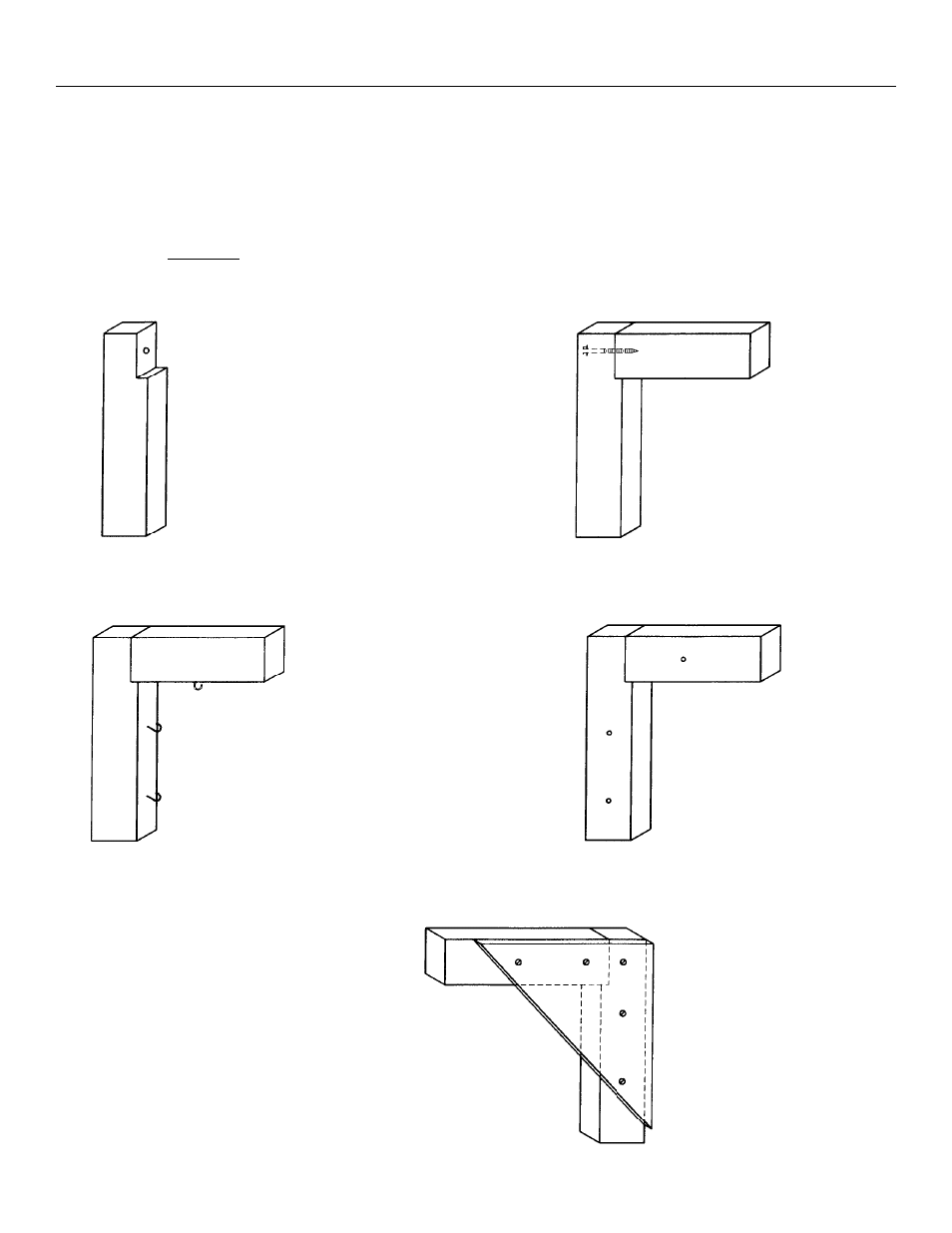

Notching

2" x 4" stock. Notch 2 vertical

(shortest) pieces as shown.

2" x 6" stock is notched

longer and deeper.

Bolting Frames

Drill 7/16" hole through notched

pieces. Drill 1/4" hole into ends of

horizontal pieces. Use 3/8" lag bolt

with washer on 2" x 4" frames at

corners. Use same lag bolts and

washers for 2" x 6" stock.

Lacing Hooks

Place #8 screw hooks 4-1/2" from

inside of corners. Space all others

6" apart. Measurements are same

for frames of 2" x 4" and 2" x 6" stock.

Lacing With Roofing Nails

Use large head roofing nails on face

of frame. Frame is now ready for

lacing screen into position.

Bracing

Bolt 2" x 4" corner braces to

back of frame at all corners

or gusset plates as illustrated.

On 2" x 6" stock frames, up to

20' width, uses braces 8' long.

10' braces for 20' to 24' widths

and 12' braces for widths

over 24'.