Suggested specifications – A.O. Smith HW 300 THRU HW 610 User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE:

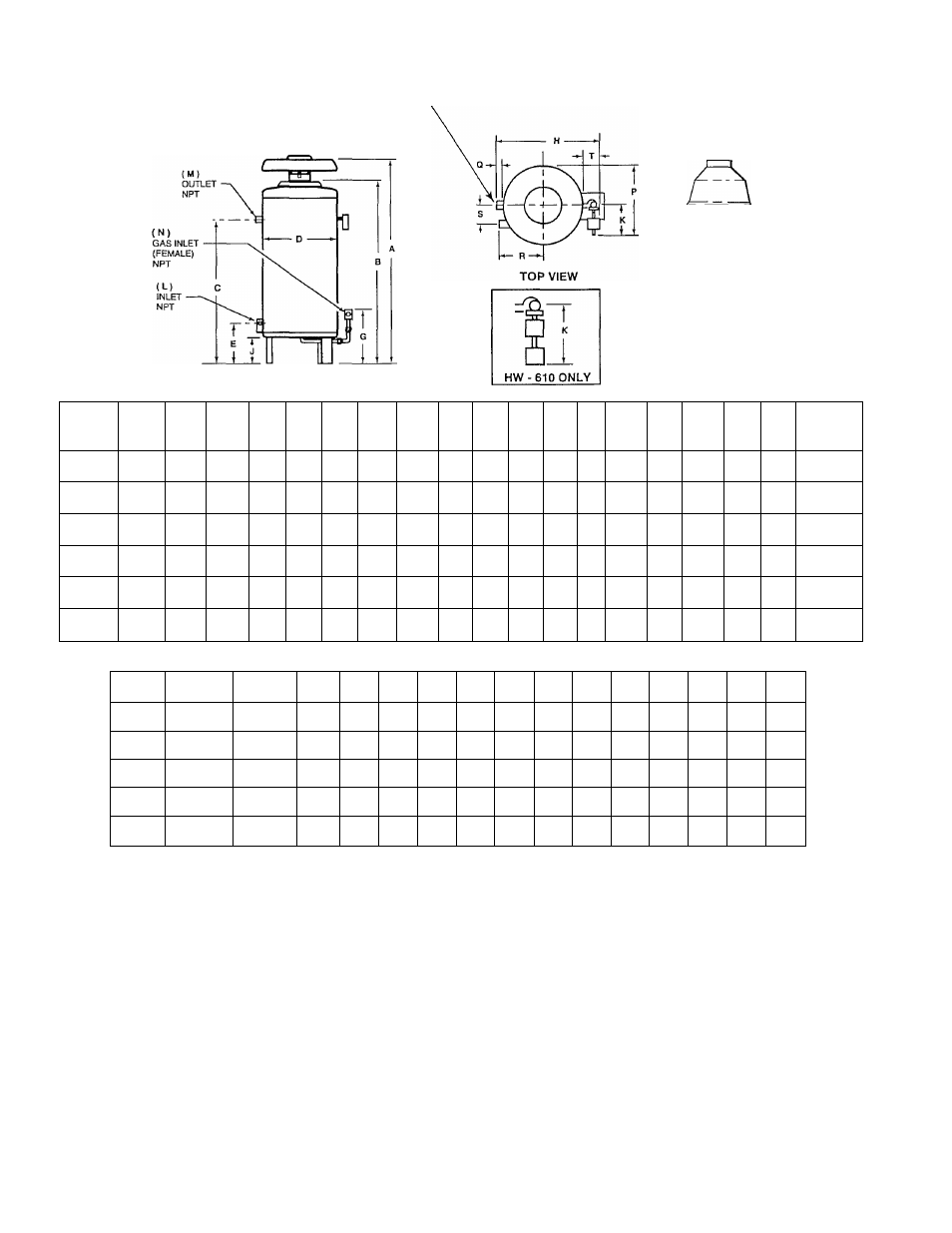

TOP MANIFOLD HAS EXTRA OPENINGS FOR THERMOMETER 3/4“

(19MM) AND RELIEF VALVE 1“ (25MM) [HW-520 AND -610 ONLY]

HW - 300 ONLY

HW-610

NATURAL GAS

ONLY

ALL DIMENSIONS IN INCHES (MM)

Models

A

В

C

D

E

F

G

H

J

К

L

M

N

P

Q

R

S

T

Approx.

Ship. Wt.

Lbs. (Kgs.)

HW-300

65

(1651)

43-1/4

(1099)

36

(914)

25-1/4

(641)

12

(305)

8

(203)

16-1/2

(419)

29-5/8

(753)

9

(229)

14

(356)

1-1/4

(32)

1-1/4

(32)

3/4

(19)

26-5/8

(676)

1

(25)

10-1/8

(257)

5-3/8

(137)

5

(127)

240

(109)

HW-399

57-1/8

(1451)

45-1/8

(1146)

38-3/4

(984)

27

(686)

12

(305)

10

(254)

16-3/4

(425)

31-1/2

(800)

9

(229)

14

(356)

1-1/2

(38)

1-1/2

(38)

1

(25)

27-1/2

(699)

1

(25)

11-1/4

(286)

5-1/2

(140)

5

(127)

291

(132)

HW-420

57-1/8

(1451)

45-1/8

(1146)

38-3/4

(984)

27

(686)

12

(305)

10

(254)

16-3/4

(425)

31-1/2

(800)

9

(229)

14

(356)

1-1/2

(38)

1-1/2

(38)

1

(25)

27-1/2

(699)

1

(25)

11-1/4

(286)

5-1/2

(140)

5

(127)

291

(132)

HW-520

68-5/16

(1735)

56-1/4

(1429)

46

(1168)

27

(686)

12

(305)

10

(254)

18

(457)

36-1/2

(927)

9

(229)

11

(279)

2

(51)

2

(51)

1

(25)

24-1/2

(622)

3-1/2

(89)

12

(305)

5-3/4

(146)

7

(178)

361

(164)

Propane

HW-610

67

(1702)

56-1/4

(1429)

46

(1168)

27

(686)

12

(305)

12

(305)

18

(457)

36-1/2

(927)

9

(229)

11

(279)

2

(51)

2

(51)

1

(25)

24-1/2

(622)

3-1/2

(89)

12

(305)

5-3/4

(146)

7

(178)

361

(164)

Natural

HW-610

64-3/4

(1645)

56-1/4

(1429)

46

(1168)

27

(686)

12

(305)

12

(305)

18

(457)

36-1/2

(927)

9

(229)

11

(279)

2

(51)

2

J51]_

1

(25)

24-1/2

(622)

3-1/2

(89)

12

(305)

5-3/4

(146)

7

(178)

361

(164)

SPECIFICATIONS AND RECOVERY CAPACITIES

TEMPERATURE RISE

INPUT

Temp. (C)

11

17

22

26

33

39

44

50

56

61

67

72

78

Model

BTUH (KW)

Rise (F)

20

30

40

50

60

70

80

90

100

110

120

130

140

HW-300

300,000

LPH

5,505

3,670

2,753

2,202

1,835

1,573

1,376

1,223 1,001

1,001

918

847

786

(88)

GPH

1,455

970

727

582

485

416

354

323

291

264

242

224

208

HW-399

399,000

LPH

7,322

4,882

3,661

2,929

2,441

2,092

1,831

1,627

1,464

1,331

1,220

1,127

1,046

(116)

GPH

1,935

1,290

967

774

645

553

484

430

387

352

322

298

276

HW-420

420,000

LPH

7,708

5,138

3,854

3,083

2,569

2,202

1,927

1,713 1,542

1,401

1,285

1,186

1,101

(123)

GPH

2,036

1,358

1,018

815

679

582

509

453

407

370

339

313

291

HW-520

520,000

LPH

9,543

6,362

4,771

3,817

3,181

2,727

2,386

2,121

1,909

1,735

1,590

1,468

1,363

(152)

GPH

2,521

1,681

1,261

1,008

840

720

630

560

504

458

420

388

360

HW-610

610,000

LPH

11,194

7,463

5,597

4,478

3,731

3,198

2,799

2,488

2,239

2,035

1,866

1,722

1,599

(179)

GPH

2,958

1,972

1,479

1,183

986

845

739

657

592

538

493

455

423

Recovery capacity ratings are heater performance at an assigned 76% thermal efficiency. Actual recoveries are higher.

NOTE: To compensate for the effects of high altitude areas above 2.000 feet (610m), input and output rating should be

reduced approximately 4% for each 1,000 feet (305m) above sea level.

SUGGESTED SPECIFICATIONS

Boiler{s) for hot water supply purposes shall be Model(s) No..

. as manufactured by A. O. Smith or an approved equal. Boiler(s)

shall be gas-fired, and design certified by the Canadian Gas Association or an approveri/accredited independent rating laboratory, capable of

supplying______ GPH (LPH) at 100°F (56°C) temperature rise equipped to burn________________ gas, with input rating of________ BTUH(KW)/hr. and

bearing the ASME code symbol. Boiler(s) shall be up flow type having all non-ferrous waterways, and employing a copper finned heat exchanger

and a tightly wound copper coil combustion chamber with 160 psi (1100 kPa) working pressure rating, Boiler(s) shall be equipped with an electric

gas valve of the step-opening type, an adjustable limit control which will break the electric circuit on temperature rise, intermittent ignition with one

(1) second shutdown in the event of pilot flame failure (propane models equipped with standing pilots), a gas pressure regulator properly set for the

gas to be supplied, and a coil limit switch for shut off in event of excessive water temperature, a thermal balancer, a certified draft diverter and a fully

illustrated instruction manual. Certified for combustible flooring. Outer jacket shall be of baked enamel finish. The coil, heat exchanger and burner

shall have a five year limited warranty as outlined in the written warranty.

A. 0. Smith Enterprises Ltd.

Water Products Company

A Subsidiary of A. O. Smith Corporation

Stratford, Ontario

El Paso, Texas

McBee, South Carolina

Seattle, Washington

Veidhoven, The Netherlands

A. O. Smith Corporation reserves the right to make product changes

or improvements at any time without notice.

A012.0C

> A. O. Smith Corp., 1996

Printed in U.S.A.