Depressed-center wheels, Wire brushing – Black & Decker 6112 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

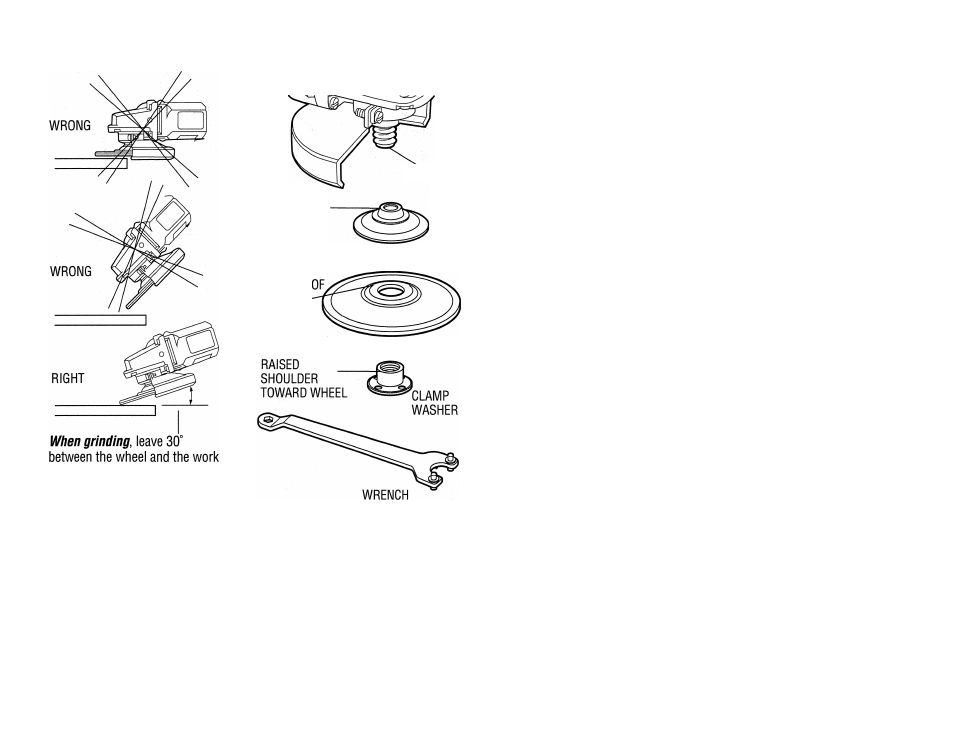

Figure 5

as shown above.

M/ften

sanding,

leave 10°-15°

between the wheel and the work.

Figure6

SPINDLE

RAISED

PORTION OF

FLANGE

TOWARD

SPINDLE

RAISED

PORTION

WHEEL

TOWARD

FLANGE

BACKING FLANGE

DEPRESSED CENTER WHEEL

Depressed-Center Wheels

Depressed center wheels may be used for moderate metal removal on flat or

contoured surfaces.

CAUTION:

Never use depressed center wheels without the

proper guard.

To install depressed center wheels:

(See Figure 6)

1. TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

2. Be sure the guard assembly is securely attached to the spindle housing.

Position guard so that the open part of the guard is facing away from the

operator.

3. Put the backing flange onto the tool spindle.

4. Check rated speed on depressed center wheel. Never use wheel with rated

speed lower than the speed in the “WARNING” statement on the nameplate

of the tool.

5. Place the depressed center wheel on the tool spindle.

6. Thread the clamp washer on tool spindle, hold the tool spindle by engaging

the lock button, and tighten clamp washer with wrench.

When using a depressed center wheel, hold the tool so that an angle of approx

imately 30° exists between the wheel and the work. (See Figure 5)

Wire Brushing

Common applications for wire cup brushes include cleaning welds, angles,

corners and removal of paint.

1.

Disconnect tool from power source. Rest grinder on its back with spindle

facing up.

2. Ensure that the rated speed of the wire brush is equal to or higher than the

rated speed of the grinder found on the nameplate.