Grounding (continued), Grounding, Attaching discs – Black & Decker 4040 User Manual

Page 2: Operation, Cleaning, Tools grounding (continued), Safety rules for power

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SAFETY RULES

FOR POWER

TOOLS

GROUNDING (continued)

1. KEEP

mmm

IIE

ä

clean

, cluttered areas and benches

invite accidents.

2.

A¥OID

DANGEROUS

EifllONMENT.

Dont

expose

power

tools to rain. Don't use power tool in damp or^ wet loca

tions. And keep work area well lit.

3. KEEP CHILDIEM AWAY. All visitors should be kept safe

distance from work area,

4.

STOiE IDLE TOOLS, When not in use, tools should be

stored in dry, high or locked-up place—-out of reach of

children.

5.

FOiCE TOOL. It will do the job better and safer

at the rate for which it was designed.

6.

USE SIGHT TOOL. Don't force small tool or attachment

to do the job of a heavy duty tool.

7. WEAi PlOPEl APPllEL. Mo loose clothing or jewels to

get caught in moving parts. Rubber gloves and footwear '

are recommended when working outdoors.

8.

USE SAFETY GLASSES with most tools. Also face or

dust mask if cutting operation is dusty.

i.

DON'T ABUSE CORD. Never carry tool by cord' or yank if

to disconnect from receptacle. Keep cord from heat, oil ^

and sharp edges.

10. SECURE WÖRK. Use clamps or a vise to hold work. It's :

safer than using your hand and it trees both hands to ;

operate tool.

|

11

-

DON'T OVERREACH.

Keep proper footing and balance |

at all times.

12.

MAINTAIN

TOOLS WITH CARE. Keep tools sharp at all

^ times, and clean for best and safest performance. Follow

, instructions for lubricating and changing accessories.

13.

DISCONNECT TOOLS.

When not in use, before servicing;

when changing accessories such as blades, bits, cutters,

etc.

14.

REMOVE

ADJUSTING

KEYS

AND

WRENCHES.

Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

15.

AVOID ACCIDENTAL STARTING: Don't carry plugged-in.

tool with finger on switch. Be sure switch Is “OFF” when

plugging in.

16.

OUTDOOR USE EXTENSION CORDS—When tool is used

outdoors, use only extension cords suitable for use out

doors and so marked.

17.

DO NOT OPERATE portable electric tools in gaseous or

explosive atmospheres. Motors in these tools normally

spark, and the sparks might ignite fumes.

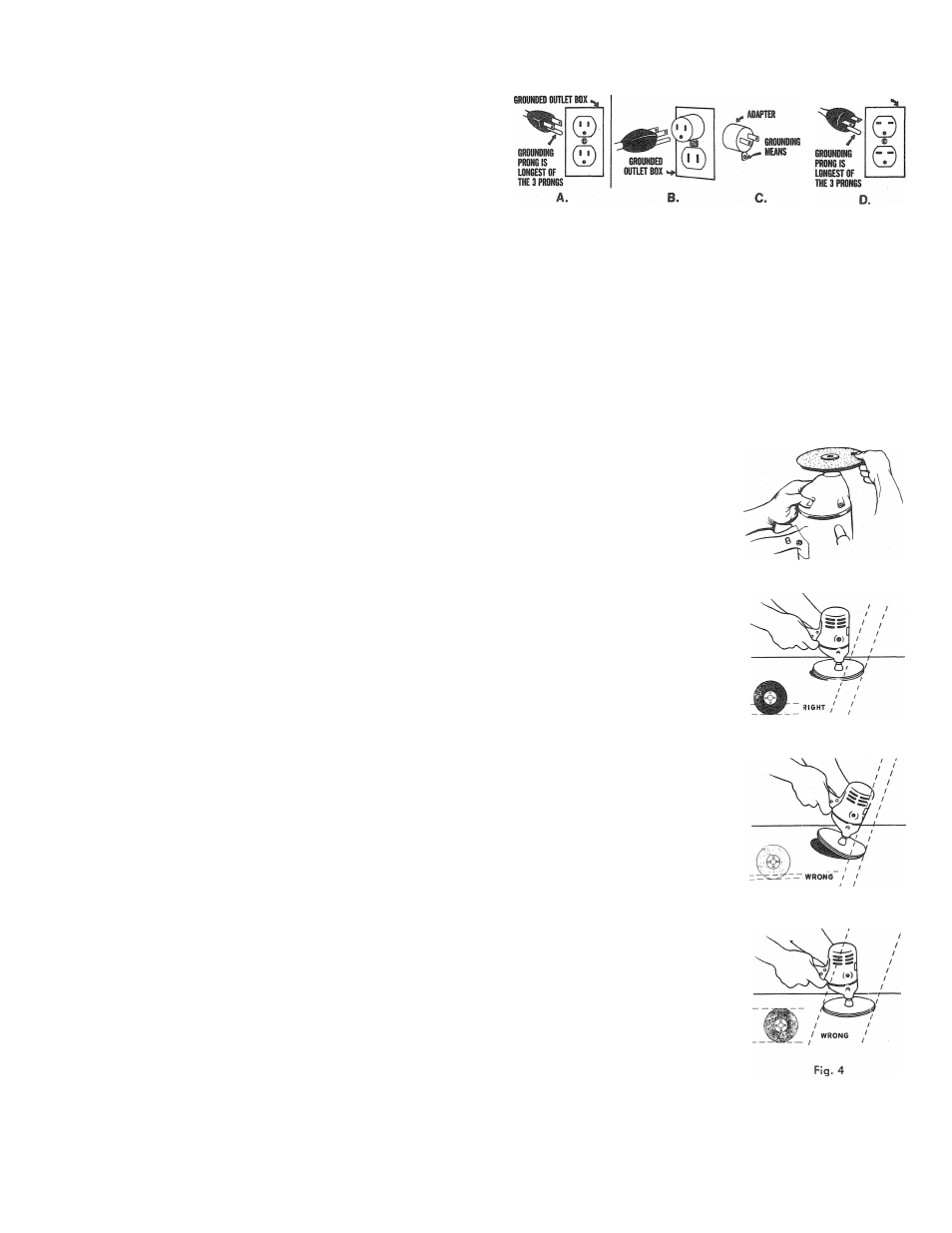

GROUNDING

This tool should be grounded while in use to protect the operator

from electric shock. The tool is equipped with an approved

three-conductor cord and three-prong grounding type plug to fit

the proper grounding type receptacle. The green (or green and

yellow) conductor in the cord is the grounding wire. Never

connect the green (or green and yellow) wire to a live terminal.

If your unit is for use on less than 150 volts, it has a plug like

that shown in Figure A. If it is for use on 150 to 250 volts, it has

a plug like that shown in Figure D. An adapter, Figures B and C,

is available for connecting Figure A plugs to two-prong recep

tacles. The green-colored rigid ear, lug, etc., must be connected

to a permanent ground such as a properly grounded outlet box.

No adapter is available for a plug as shown in Figure D.

Adapter shown in Figures B & C is Not for Use in Canada.

0«}UNDEO OUTLET BOX

We recommend that you NEVER disassemble the tool or try to

do any rewiring in the electrical system. Any repairs should be

performed only by

B&D

Service Centers or other qualified

service organizations. Should you be determined to make a

repair yourself, remember that the green colored wire is the

“grounding" wire. Never connect this green wire to a “live”

terminal. If you replace the plug on the power cord, be sure to

connect the green wire only to the grounding (longest) prong

on a 3-prong plug.

To start tool, depress trigger: to stop, release trigger. To lock

trigger in

“ON”

position for continuous operation, depress

trigger, push in locking button, and release trigger. To release

locking mechanism and turn off tool, depress trigger and release.

ATTACHING DISCS

1. Place Backing Pad and sanding

disc on spindle of toot.

2. Screw Clamp Washer PARTIALLY

on the spindle.

3. V'/ith one hand, depress the spin

dle lock button and hold the

button down. Grasp the pads and

sanding disc with the other hand

and turn by hand to tighten the

entire assembly (fig. 1).

To remove pads and discs: depress

spindle lock button: grasep the pads

and disc: and turn pad and disc

assembly in opposite direction.

OPERATION

Rg. I

Grasp the control handies firmly and

operate the tool freely without forced

effort or unnecessary pressure. For

maximum efficiency, the tool must

be positioned so that the sanding

disc is at the proper angle to the

work. Fig., 2 (marked “RIGHT”) illus

trates how the tool is tipped slightly

in order to let the maximum amount

of abrasive contact the work without

affecting the smoothness of the sand

ing action. Fig. 3 and Fig. 4 (marked

“WRONG”) show incorrect positions

which allow either too little or too

much abrasive contact. If only the

outer edge of the sanding, disc is

used (as in Fig. 3), a rough cut sur

face will result. If the sanding disc

is pressed flat against the work (as

in Fig. 4), the cutting action will be

irregular and bumpy, and the toot

will be difficult to control.

CLEANING

Blowing dust and grit out of the main

housing by means of an air hose is

recommended and may be done as

often as dirt is seen collecting in and

around the ventilator vents. The

motor should be running while air

is being blown into the air vents.

Fig. 2

Fig.3