Grounding, Extension cord, Motor brushes – Black & Decker 44502-02 User Manual

Page 2: Commercial, Industrial use warranty, Attaching hammer tools, Operation, Lubrication, Hammer supplies, Commercial/ industrial use warranty

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

t

4

-

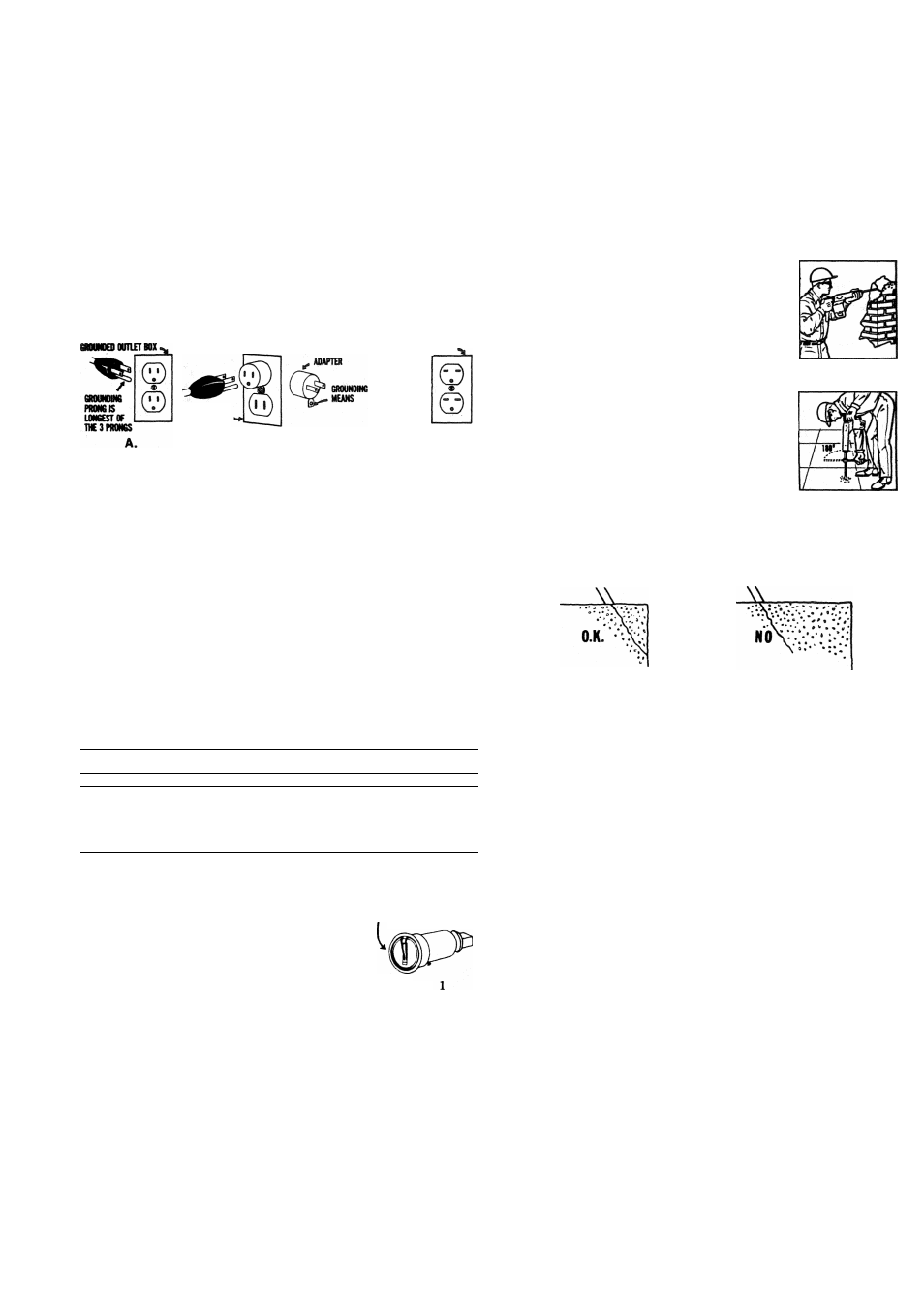

GROUNDING

This tool should be grounded while in use to protect the operator

from electric shock. The tool is equipped with an approved

three-conductor cord and three-prong grounding type plug to fit

the proper grounding type receptacle. The green (or green and

yellow) conductor in the cord is the grounding wire. Never

connect the green (or green and yellow) wire to a live terminal.

If your unit Is for use on less than 150 volts, it has a plug like

that shown in Figure A. If It is for use on 150 to 250 volts, it has

a plug like that shown in Figure D. An adapter, Figures B and C,

is available for connecting Figure A plugs to two-prong recep

tacles. The green-colored rigid ear, lug, etc,, must be connected

to a permanent ground such as a properly grounded outlet box.

No adapter is available for a plug as shown in Figure D. Adapter

shown in Figures B & C is Not for Use in Canada.

a«)U№Q) OUTLET gOK

GftoiMe

OUTLET BOX

/

6R0UNDIN6

PRONG IS

LOHKSTSH^

THE3PR0HGS

B.

c.

D.

We recommend that you NEVER disassemble the tool or try to

do any rewiring in the electrical system. Any repairs should be

performed only by B&D Service Centers or other qualified

service organizations. Should you be determined to make a

repair yourself, remember that the green colored wire Is the

“grounding" wire. Never connect this green wire to a “live"

terminal. If you replace the plug on the power cord, be sure to

connect the green wire only to the grounding (longest) prong

on a 3-prong plug.

EXTENSION CORD

When using the tool at a considerable distance from power

source, a 3-conductor, grounding-type extension cord of ade

quate size must be used for safety, and to prevent loss of power

and over-heating. Use the table below to determine the mini

mum wire size required in an extension cord.

Use only three wire extension cords which have three-prong

grounding-type plugs and three-pole receptacles which accept

the tool's plug. Replace or repair damaged cords.

Ampere rating

Oto

2.10

to

3.5 to

5.10 to

7.10 to

12.1

to

(on nameplate)

2.0

3.4

5.0

7.0

12.0

16.0

Ext. Cable length

Wire Size (A.W.G.)

25 ft.

18

18

18

18

16

14

50 ft.

18

18

18

16

14

12

75 ft.

18

18

16

14

12

10

100

ft.

18

16

14

12

10

150 ft.

16

14

12

12

—

—

200

ft.

16

14

12

10

—

—<

RETAINING SPRING

Fig.

MOTOR BRUSHES

Inspect carbon brushes regularly. First, unplug

the tool, then press together the two prongs

of the Retaining Spring (see Fig. 1) and re

move spring. Unscrew brush cap and remove

brush and spring assembly. Replace when

brushes are worn down to the identifying

letter or groove, or when spring exerts insuf

ficient pressure to hold brush against com

mutator. Keep brushes clean and sliding freely

in guides.

COMMERCIAL/

INDUSTRIAL USE WARRANTY

Black & Decker warrants this product for one year from the

date of purchase. We will repair without charge, any defects

due to faulty material or workmanship. Please return the com

plete unit, transportation prepaid, to any Black & Decker Ser

vice Center or Authorized Service Station listed under “Tools

Electric" in the yellow pages. This warranty does not apply to

accessories or damage caused where repairs have been made

or attempted by others.

Fig. 2

Fig. 3

ATTACHING HAMMER TOOLS

First, swing the Tool Retaining Spring (located in front of the

nose piece) to one side. Insert tool bit into nose piece until

shoulder on tool bit bottoms on nose piece. (NOTE: If tool bit

does not bottom, hold Hammer so that tool bit is touching the

ground, and push the Hammer sharply downward to seat the

tool bit.) Next, swing Tool Retaining Spring back into place so

that ft engages the shaft of the tool ‘bit.

OPERATION

Grasp handle of Hammer with one hand, and

the barrel of Hammer with the other hand

(see Fig. 2). If using Star Drills, grasp Ham

mer handle and the Turning Handle (see Fig.

3). Place tool in working position and depress

trigger. When using Star Drills, swing Turning

Handle in a 180° arc about 30 times per min

ute to prevent binding and to remove cuttings;

exert firm even pressure for best results.

NOTE: Use Dust Shield for all overhead

drilling.

For best demolition performance always place

the end of the bit close to an edge of the

work, breaking the work away piece by piece

(Fig. 4). Trying to break away too large a chunk may cause the

bit to get stuck in the work and may also decrease demolition

rate.

Fig. 4

LUBRICATION

The most important point in keeping your Electric Hammer free-

running and powerful Is regular oiling. Oil cups are located in

the gear case under the switch handle. Oil liberally (several

squirts from the can) after every 3 hours of Hammer operation.

In overhead work, oil Hammer, through the nose piece rather

than through the oil cups. Excess oiling will cause some leakage

around the tool shank, but this does no damage and Hammer

will clear Itself rapidly in operation.

Black & Decker Special Hammer Oil (See Hammer Supplies,

this booklet) has special qualities for adhering to high speed

working parts and will greatly prolong the life of the tool. In an

emergency, use high grade SAE No. 30 Oil.

In from 30 days to 3 months, depending upon use, your Ham

mer sould be sent to the nearest B&D Service Branch for a

complete cleaning and replacement of lubricant In the gear case.

Your Hammer will be returned to you completely cleaned and

adjusted with new parts installed where necessary.

HAMMER SUPPLIES

Cat. No. 51315 Special Hammer Oil, 1 pint can

Cat. No. 60541 Hammer Gear Grease, 1 lb. can

Cat. No. 7276 Drift Key (To remove tapered shank bits from

chuck)

Cat. No. 10909 Tool Retaining Spring, & 1" Hammers

Cat. No. 21750 Tool Retaining Spring, IVi" Hammer

Cat. No. 17746 Dust Shield for Wrenches Nos. 22587, 23806,

and Chuck Head 22510.

Cat. No. 17747 Dust Shield for Wrenches Nos. 22749, 22854