Charging procedure, Chuck & key, Trigger switch & control button – Black & Decker 1941 User Manual

Page 2: Lock-‘‘off, Forward, Reverse, Charging the power pack, Operation, Drilling (figúrelo)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

IMPORTANT CHARGING NOTES

1. Longest fife and best performance can b© obtained if the

batteries are charged when the air temperatyr# is aboyt

75®F. 00 NOT charge the batteries In an air teroperatyre

below

4

-

40

®F or above -f 105®F. This Is importarit and will

prevent serloys daimag© to the batteries.

2 When yoy charge yoyr power pack for the first time, or

after prolonged storage, it will only accept about an 80%

charge. However, after several charge and discharge cycles,

the batteries will be up to full capacity.

3. While charging, the Charger may hum and become warm

to touch. This is a normal condition, and does not indicate

a problem.

4. If the batteries do not charge properly — (1) Check current

at receptacle by plugging in a lamp or other appliance, (

2)

Check to see if receptacle is connected to a light switch

which turns power off when you turn out the lights. (3) Move

charger and power

pack to a surrounding air temperature

of approximately 75^' F. In an extremely warm environment,

the power pack may be too hot to permit fast charging. (4)

If the receptacle and temperature are o.k., and you do not

get proper charging, take or send the tool

and^charger to

your local service center. See “TOOLS, ELECTRIC” in

yellow pages.

5. The power pack should be recharged when it falls to pro*

duce^^sufficient power on jobs which were easily done pre

viously. DO NOT CONTINUE to use under these conditions.

Repeat the charging procedure.

6. If, after repeated use, your power

pack does not take a full

charge, and produces operating time less than normal, It

may not be caused by faulty batteries. If you use the power

pack repeatedly for only a few minutes and then charge It,

the batteries build up a resistance to taking a full charge.

This resistance results In reduced operating time.

The batteries can be restored to their original power and

life by fully charging and then completely using up the

charge several times. This will recondition the batteries to

deliver

maximum

performance.

FOR REPLACEMENT OR FOR ADDITIONAL

POWER PACKS OR CHARGERS, ORDER:

No. 98003 Power Pack (

1-hr. charge)

No. 98010 Charger (

1-hr. charge)

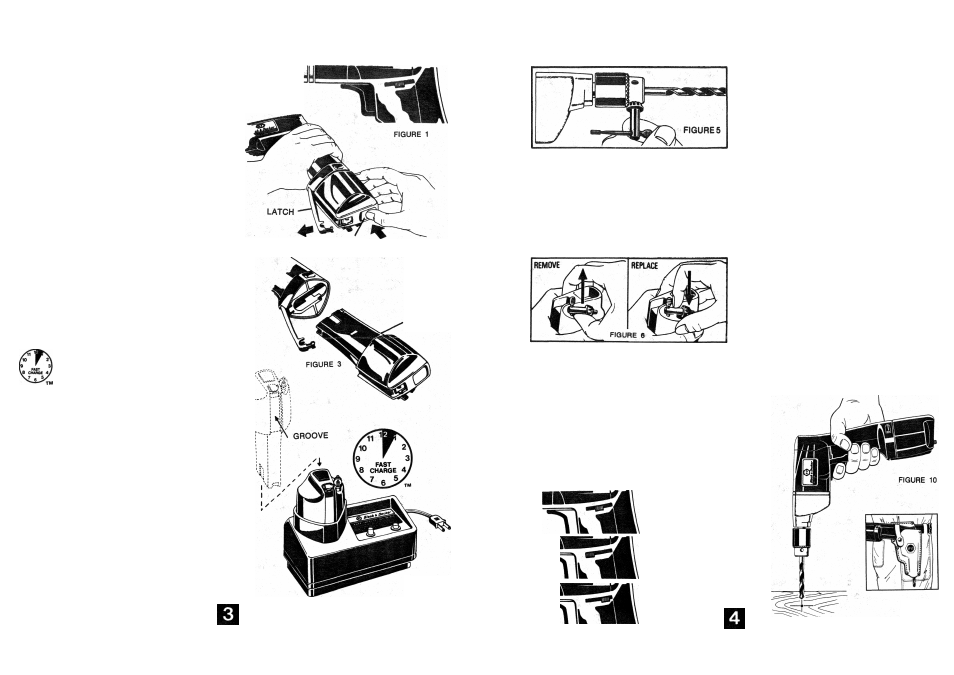

CHARGING THE POWER PACK

CHARGING PROCEDURE

1.

Move Switch Control Button to the center of Its slot to

LOCK Trigger Switch “OFF" {Figure 1).

2.

Remove Power Pack from

Tool Handle by first pressing

Release Button (Figure 2). The Latch will spring open and

allow Power Pack to be withdrawn from handle (Figure 3).

3. Place the Power Pack in the Charger as shown in Figure 4.

Note that groove in Power Pack faces front. Plug in Charger.

4. Press button momentarily until light turns “ON". Your Power

Pack is now on charge.

5. In about an hour the light will turn “OFF". Charging is now

complete and your Power Pack is ready for use.

6. When charging is completed, unplug Charger, lift Power

Pack from Charger and insert Power Pack into tool handle.

Press latch over end of Power Pack until it snaps into the

locked position.

MOTE: If the Power Pack has become warm in use, and is

placed in the charger still warm, the light will not go on and

charging will not begin immediately when the button is pressed.

However, after you press the button you can leave the charger.

As the Power Pack cools down, the light will turn on and charg

ing will begin automatically. ALSO SEE INSTRUCTIONS FOR

NO. 98010/91-005 FAST CHARGER PACKED WITH UNIT.

RELEASE

BUTTON

FIGURE 2

POWER

PACK

FIGURE 4

TM — Trade Mark of Black & Decker

OPERATION

CHUCK & KEY

Turn chuck

collar to open chuck jaws. Place bit in chuck as far

as it will go. Tighten chuck collar by hand. Place chuck key

In

each of the three holes, and tighten in clockwise direction

(Figure 5). It's important to tighten chuck with all three holes

to prevent

bit slippage. To release bit, turn chuck key

counterclockwise in just one hole, then loosen chuck by hand.

When not in use, the chuck key can be stored in the end of the

power pack. To remove the key,

place thumb as shown in

Figure

6 and push key firmly upward out of its holding socket.

To

replace key, push key's handle firmly and completely down

into the socket (Figure

6).

TRIGGER SWITCH & CONTROL BUTTON

The Drill is turned “ON" and “OFF" by pulling and releasing

the Trigger Switch. However, the Trigger can be locked "OFF’

by positioning the Switch Control Button in the center of its

slot (Figure 7). This position should be used to prevent the

Trigger from being accidentally pressed when the tool is not

in use, when attaching or removing the Power Pack, when

attaching or changing accessories, and when cleaning or serv

icing the Drill.

For normal use, the Switch Control Button should be in the

FORWARD position (Figure

8)»

Use the REVERSE position (Figure 9) for smoothly withdrawing

bits that bind in the hole. When moving from FORWARD to

REVERSE, or vice versa, always release the trigger first as the

control button will not move when the trigger is depressed.

Move the control button to FORWARD before starting to drill

again.

LOCK-‘‘OFF”

FIGURE 7

FORWARD

FIGURE 8

REVERSE

FIGURE 9

1. Lock Trigger Switch "OFF” with switch control button when

attaching or changing bits or accessories.

2.

Use sharp drill Wti only. For WOOD, use drill bits,

spade bits, power auger bits, or hole saws. For METAL, use

high-speed steel twist drift bits. For MASONRY, such as

brick, cement, cinder block, etc., use carbide-tipped bits,

3.

Be sure the material to be drilled is anchored or clamped

firmly. If drilling thin material, use a wood “back-up" block

to

prevent damage to material.

4. Center-punch an indentation at the point to be drilled. This

will overcome

tendency of bit to slip around on a smooth

surface. Place the tip of bit in indentation and turn motor

“ON."

5.

Always apply pressure in a straight line with the bit. Use

enough pressure to keep drill biting, but do not push hard

enough to

stall motor or deflect bit. To minimize stalling on

breaking through the material, reduce pressure on drill

and

ease the bit through last part of hole.

6. Hold drill firmly to control the twisting action of the drill.

DRILLING (Figúrelo)

DiliLliG IN WOOD

Holes in wood can be made with the same twist

drill bits used

for metal or with wood augers. These bits should be sharp and

should be pulled out frequently when drilling to

clear chips

from the flutes. Work that is apt to splinter should be backed

up with a block of

wood. Let up on the pressure just before

the tip cuts through, this will

give a good clean hole.

DRILLING

IN

METAL

Use a cutting lubricant when

drilling ferrous metals. The ex

ceptions are iron and brass which should be drilled dry. The

cutting lubricants that work best are sulphurized cutting oil or

lard

oil; bacon grease will also serve the purpose. Aluminum

is best drilled with turpentine or kerosene.

LEATHER HOLSTER

To

add even more to the convenience features of your Cordless

Drill, an accessory Leather Holster is available. This Holster

fastens to your belt and keeps the Drill handy and ready for

work.

It also frees both hands when you are not actually using

the

tool. Order;

Cat. No. 98-004/91-012 Leather Holster (Figure 11)

FIGURE 11