806 m2 m – Bard 2100-073 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BARD KANUFACTURING COMPANY

DUAL FURL ADO-OH HEAT PUMP GUIDE TO ENERGY COST SAVINGS

X

REGIO» S

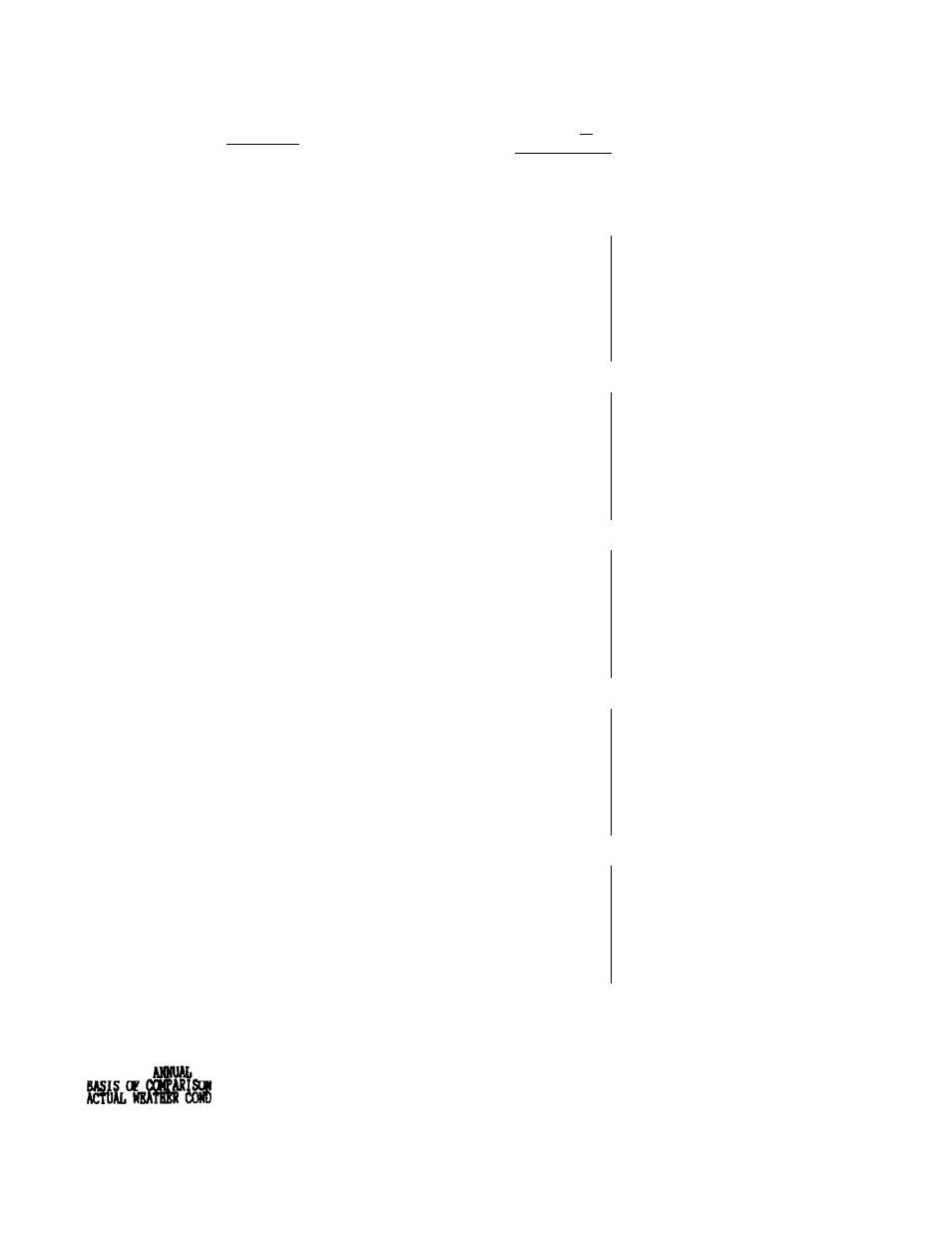

ffiAIlHG CAPACITY AT iS DEG.F.ENTERING HATER TEMP.: ______

FURNACE TYPE NATURAL~GAS

FURNACE EFFTUTENCY

wm

BTu6.^^ COP

Y TCTtME

BEAT ELEC.

.35 .40 ,45 NATURAL

.50 .55GAS COST -

.60 .65 S/THERH

.70 .75 .80 .90 1.00

25,000

S 236 271 299 333 368 403 438 473 507 542 605 674

.05 S 271 271 271 278 278 278 285 285 285 292 299 299

.06

$

319 319 319 326 326 326 333 333 333 340 347 347

.07 S 375 375 375 382 382 382 389 389 389 396 403 403

.08

424

431

438 438 433 445 452 452

,09 5 473 473 473 479 479 479 486 486 486 493 500 500

.10

521 521 521 528 528 528 535 535 535 542 549 549

.12 S 626 626 626 633 633 633 639 639 639 646 653 653

.14 S 723 723 723 730 730 730 737 737 737 744 751 751

.16

$

827 827 827 834 834 834 841 841 841 848 855 855

30,000

$

278 319 361 403 445 486 528 563 605 646 730 813

.05 s 313 319 319 326 326 333 333 333 340 340 347 354

.06

$

375 382 382 389 389 396 396 396 403 403 410 417

•22 s 431 438 438

445 452 452 452 459 459 466 473

.08

$

493 500 500 № 7 507 514 514 514 521 521 528 535

.09

$

549 556 556 563 563 570 570 570 577 577 584 591

.10

$

612 619 619 626 626 633 633 633 639 639 646 653

.12 s 730 737 737 744 744 751 751 751 758 758 765 772

.14

s

848 855 855 862 862 869 869 869 876 876 883 890

.16 s 959 966 966 973 973 980 980 980 987 987 994 1001

35,000

s 326 375 424 473 521 563 612 660 709 758 848 946

.05

s

361 361 368 375 382 389 396 396 403 410 424 431

,06

s

431 431 438 445 452 459 466 466 473 479 493 500

.07 5 493 493 500 507 514 521 528 528 535 542 556 563

.08

$

556 556 563 570 577 584 591 591 598 605 619 626

.09

s

626 626 633 639 646 653 660 660 667 674 688 695

.10

s

688 688 695 702 709 716 723 723 730 737 751 758

.12

$

820 820 827 834 841 848 855 855 862 869 883 890

.14

s

,946 946 952 959 966 973 980 980 987 994 10081015

.16 s 107810781085109210991106111211121119112611401147

40,000

s 375 431 486 542 591 646 702 758 813 862 9731085

.05

s

403 410

431 438 445 452 459 466 479 493 507

.06

$

473 479 486 500 507 514 521 528 535 549 563 577

.07

$

549 556 563 577 584 591 598 605 612 626 639 653

:§l

.10

s

s

6sl 626

695

653

723 660

730 667

737 674

744 681

751 695

765 709

779 723

793

s

758 765 772 786 793 799 806 813 820 834 848 862

.12

$

,897 904 911 925 932 939 946 952 959 973 987 1001

.14

s

103610431050106410711078108510921099111211261140

.16 5 117511821189120312101217122412311238125212661279

50,000

$

473 542 605 674 744 813 876 946 1015108512171356

.05

$

493 521 549 577 605 626 653 681 709 737 793 841

.06

$

556 584 612 639 667 688 716 744 772 799 855 904

s

s

619

681

W

730

793

I I I

UÌ 806

869 834

897 862

925 918

980 966

1029

.09

$

744 772 799 827 855

B i b

904 932 959 98710431092

:1S

1

806

M2 M

9

862

98? 890

1015 918

1043 939

1064 966

1092

1022

114? 1050

11751106

12311154

1279

.14

$

105710851112114011681189121712451272130013561405

.16

s

117512031231125912861307133513631391141914741523

674 <”THEORETICAL HEATING COST * FURNACE ONLY

THEORETICAL HEATING COST • FURN.+ HEAT PUMP

S PER YEAR

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

S PER YEAR

BALANCE POINT 15- DEG.F.

THEORETICAL HEATING COST * FURN.+ HEAT PUMP

S PER YEAR

BALANCE POINT 3- DEG.F.

<-THEORETICAL HEATING COST * FURNACE ONLY

THEORETICAL HEATING COST

S PER YEAR

FURH.+ HEAT PUMP

BALANCE POINT 5 DEG.F.

<-THEORETICAL HEATING COST * FURNACE ONLY

THEORETICAL BEATING COST

S PER YEAR

FURN.+ HEAT PUMP

BALANCE POINT 17 DEG.F.

ANNUAL AIR CONDITIONING COST WHEN COOLING LOAD IS SIZED TO MATCH COOLING CAPACITY OF HEAT PUMP

.05

35

.06

42

.07

50

.08

57

.09

64

.10

71

.12

85

.14

100

,16

114

<-ELECTRIC RATE S/KHH

<-THEORETlCAL AIR CONDITIONING COST

TBB ABOVE

HEATING AND COOLING OPERATING COSTS ARB THEORETICAL ESTIMATES ONLY AND ARE PROVIDED FOR A COMMON

"" BETHBEN VARIOUS HPES OF HEATNG AMD COOLING SYSTEMS. ACTUAL VALUES HAY VARY DEPENDING ON

ITI^ AND INDIVIDUAL USAGE PAHEi