Maintenance by qualified service personnel, Starting a boiler that has a manual pilot ignition – Bryant 39006DP4-A User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

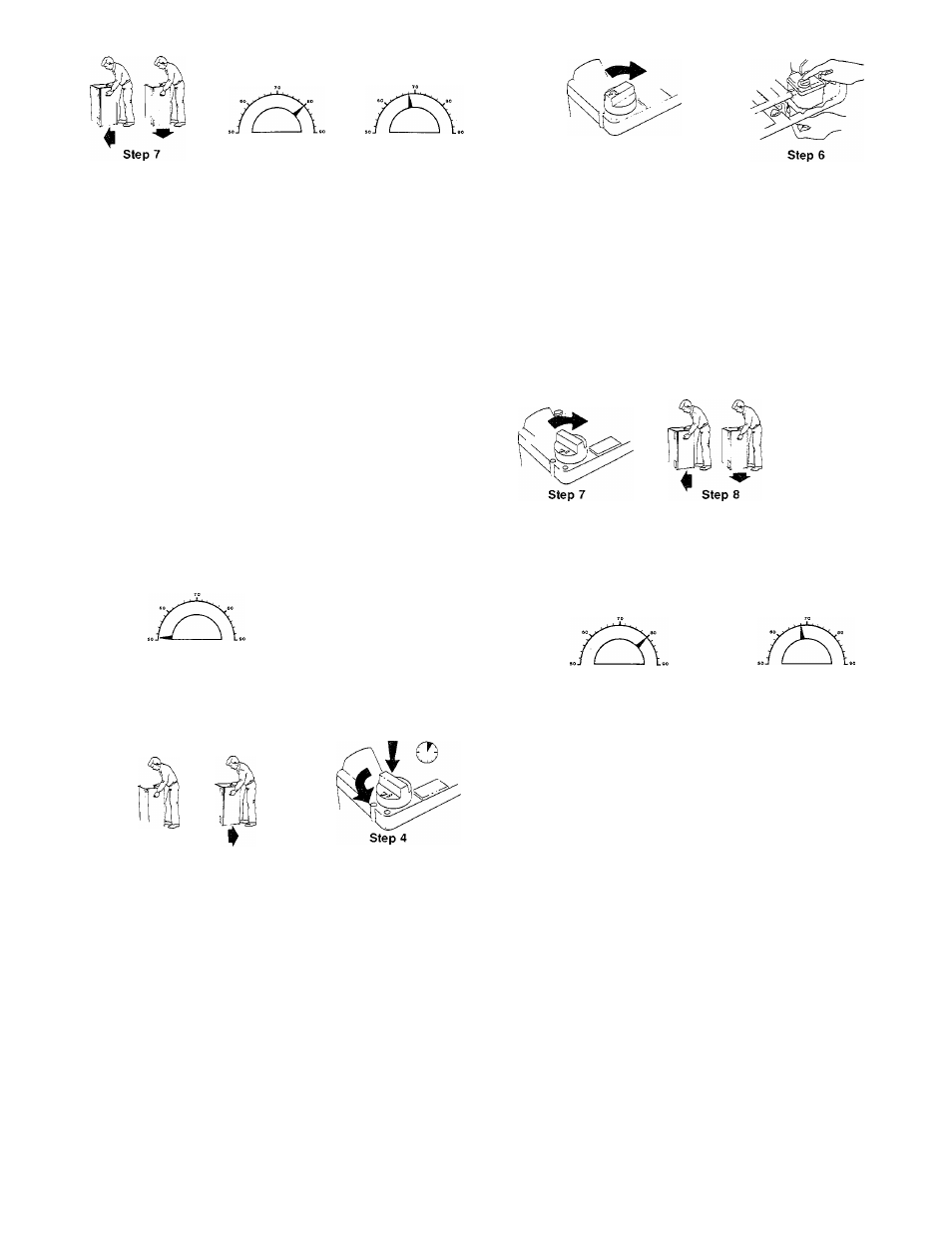

step 8

Step 9

Step 7— Replace the control access door (if applicable).

Step 8— Set the room thermostat temperature selector

slightly above room temperature to start your

boiler.

Step 9— The pilot ignition system now begins sparking and

the pilot flame lights. After a 40- to 70-second time-

delay that takes place while the system is auto

matically verifying that a pilot flame has been es

tablished, the gas valve opens, permitting gas to

flow to the main burners, and the pilot lights the

burners. Now set the temperature selector on your

room thermostat to your personal comfort setting.

\VAIl\I.\(r:

If

tlie

uiloi

faiN

lo

light,

or

the

rnmn

burners fail In light, 'hut nownyour linile>‘iSeo iirn-

eedures in this section, i .nticl call \'our ilt'.ale'’ for service.

Starting a boiler that has a manual pilot

ignition

After you have familiarized yourself with the procedures

that must be followed, and all the applicable warnings and

cautions that appear in the “Boiler Startup and Shutdown”

section of this manual, proceed as follows to start your

manual-ignition-type boiler.

\

Step 1

Step 2

Step 1-

Set your room thermostat to the lowest tempera

ture setting.

Step 2— Turn OFF the electrical supply to your boiler

(if applicable).

Step 3—

Step 4—

Step 3

Remove the boiler control access door (if appli

cable). See Figure 3.

Depress the control dial on the gas valve and

turn the control dial to the OFF position. Wait

5 minutes.

Step 5

Step 5— After waiting 5 minutes, turn the control dial on

the gas valve to PILOT position.

Step 6— Place a lighted match or other suitable source of

flame near the top of the pilot, depress the con

trol dial on the gas valve, and hold it down. Pilot

will light. Continue to hold dial down for at least

60 seconds. Release the control dial. The pilot will

remain lit.

NOTE: if the pilot flame does not remain lit, repeat steps 1

through 5; however, hold control dial down for a longer

period of time (at least 90 seconds). If the pilot flame does not

remain lit after this second attempt, the thermocouple

should be checked for a possible malfunction. Call your

dealer for service.

Step 9

Step 7 — After a pilot flame has been established, turn the

control dial on the gas valve to the ON position.

Step 8— Replace the boiler control access door (if

applicable).

Step 9— Restore power to your boiler (if applicable).

Step 10-

Step 11—

Step 10

Step 11

Set the room thermostat temperature selector

slightly above room temperature to start your

boiler.

Boiler main burners should light shortly after

your room thermostat is set to “call for heat.”

Now set the temperature selector on your room

thermostat to your personal comfort setting.

W.MJNINC: If ihc main burners fail lo lighi, >niil

down your boiler ami call yoiii' dealer for .-ierviee.

NOTE: To conserve energy when the heating season has

ended, you should shut down your manually ignited pilot.

Follow the procedures in “Shutting Down Your Boiler” at

the beginning of this section.

Maintenance by Qualified Service Personnel

At least once every year, your boiler should be inspected by a

trained and equipped service person. During this inspection,

the qualified service person should at least:

1. Inspect, clean, and lubricate pump motor as required on a

PW Boiler.

2. Inspect all flue product passages including the burners,

pilot, heat exchanger drafthood, vent pipe, and vent

damper (if installed).

3. Inspect all combustion and ventilation air passages and

openings.

4. Inspect electrical wiring, connections, and components

for loose connections.

5. Check gas pipes leading to, and inside of, your boiler for

leaks.

6. Readjust the air/gas mixture if the burner flames are not

bright blue.

7. Perform an operational checkout to determine whether

your boiler is working properly, and if it requires

adjustments.

8. Check all safety controls such as safety pilot, limit switch,

pressure relief valve, etc. for proper operation.

9. Blow down low-water cutoff and check it for proper

operation.