Maintenance, Changing clutches (fig. ?) for versa-clutch only – Black & Decker Scrugun 2033-10 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

VERSA-CLUTCH FOR DRIVING A

WIDE RANGE OF FASTENERS

RPM

0-1200

NOMINAL CAPACITY

SELF THREAD SHEET

WOOD

LAG

DRILL

CUTTING METAL MACHINE

SCREWS

SCREWS

SCREWS

SCREWS SCREWS SCREWS

#12

1/4" w/pilot hole

1/4"

1/4"

3/16" CRS

1/4"

1 /4"

1. Install proper fastener driving accessory and set screwdriver for

correct rotation.

2. Adjust clutch setting. See Fig. 4.

3. Place fastener in accessory, contact workpiece and apply

pressure to seat fastener keeping clutches engaged.

4.

Upon fastener seating the clutches will ratchet. Disengage

screwdriver from fastener.

NOTE: With Versa-Clutch the operator has the ability to "override”

clutch ratchet if a fastener hits a wood knot, variable hardness in

steel workpieces or incorrect pilot holes. Increased operator

pressure will usually cause the clutches to "pick-up” and continue to

seat the fastener. Further, a quick twist of the collar will change the

clutch setting to overcome most driving difficulties and will provide

for immediate change in torque output giving the operator option to

drive a range of fastener sizes.

MAINTENANCE

CLEANING

With the motor

running,

blow

dirt

and dust out of

all

air vents with

dry air

at least once a week. Wear safety glasses when performing

this.

Exterior

plastic parts may be cleaned with a damp

cloth

and mild

detergent.

Although these parts are highly solvent resistant, NEVER

use solvents.

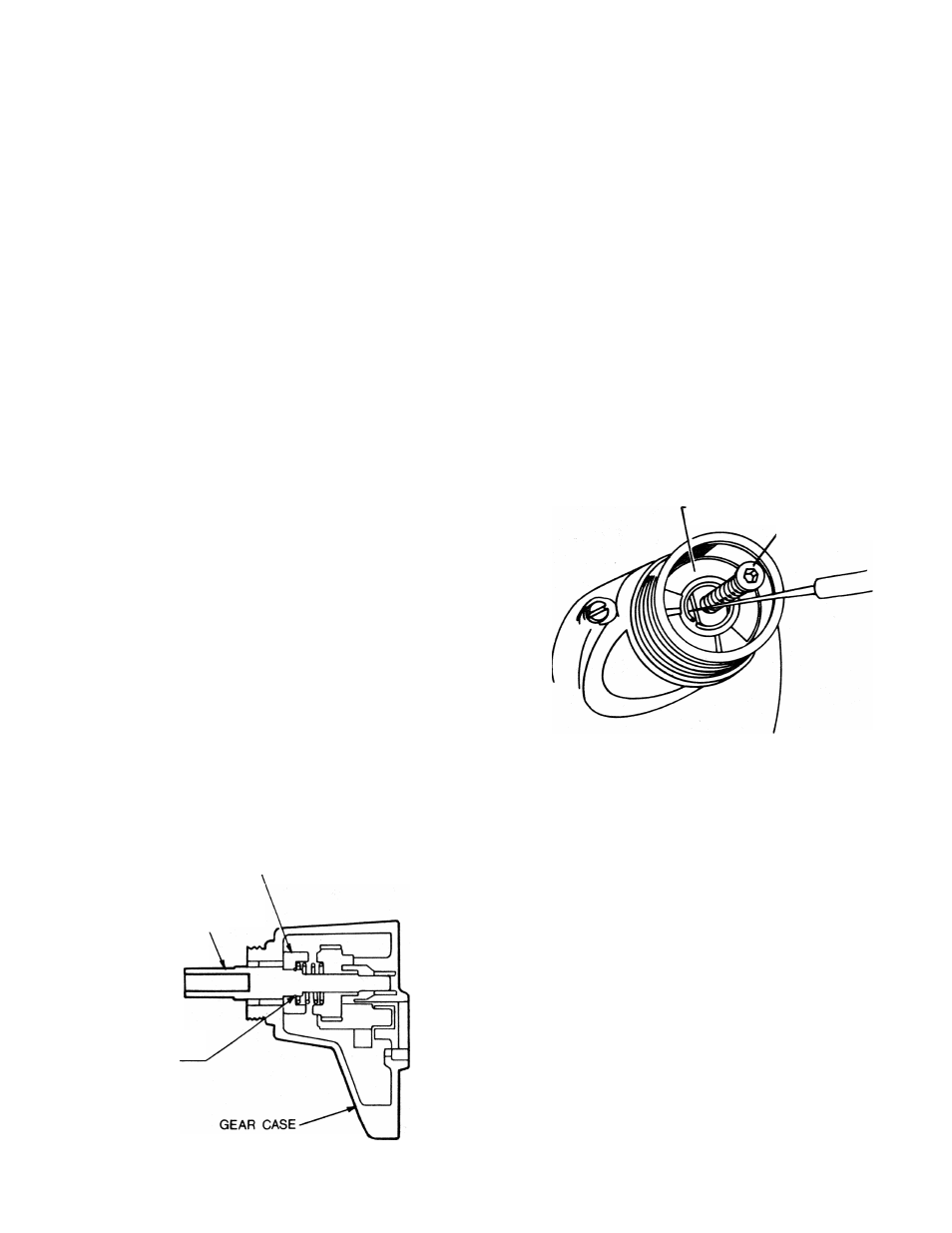

CHANGING CLUTCHES (Fig. ?) FOR VERSA-CLUTCH ONLY

1. Remove clutch housing by unscrewing in direction of arrow

(left hand thread).

2. Clamp tool or clutch housing in a resilent clamp.

3. Remove round clutch retaining rings ■ with a very small

screwdriver or sharp pointed tool.

4. Install new clutches and new retaining rings.

NOTE:

If

the output spindle slides toward Inside of gear case,

remove dead spindle spring and thread a 5/16" -18 bolt or

cap.screw into end of spindle and lift up to expose retaining

ring groove. Re-assemble dead spindle spring allowing no

more than 1/4" projecting from end of spindle.

5. Relubricate clutches. (See lubrication'

CLUTCH FACE

5/16"-18 SCREW

Figure 7

CHANGING CLUTCHES (Fig. 8) FOR POSITIVE CLUTCH & DRYWALL UNITS ONLY

CLUTCH

OUTPUT

SPINDLE

RETAINING

RING

1. Remove three gear case screws from front and disassemble

^ gear

case.

2.

Clamp output spindle

In

a resilient clamp.

3. Remove round clutch retaining rlng^ with a very small

screwdriver or sharp pointed tool.

4.

Install a new clutch and

retaining ring.

5.

Relubricate clutches and gearing. (See lubrication).

Figure 8