Changing, P.t.l safety rules for stationary power tools, Grounding – Black & Decker 4335 User Manual

Page 2: Lubrication, Motor, Wheels, Accessories, Additional grinder safety rules, Io" bench grinder

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

P.T.L SAFETY RULES

FOR STATIONARY

POWER TOOLS

1. KNOW YOUR POWER TOOL. Read the owner’s manual

carefully. Learn its .application and limitation, as well

as the specific potential hazards peculiar to this tool.

2. KEEP GUARDS II PLACE and in working order.

3. GROUND ALL TOOLS. If tool is equipped with three-

prong plug, it should be plugged into a three-hole

electrical receptacle. If an adapter Is used to accom

modate a two-prong receptacle, the adapter wire must

be attached to a known frouni. Newer remove the

third prong.

4.

REMOVE ADJUSTING * KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed before turning on tool.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

6

.

AVOID DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations. Keep your work area

welt illuminated.

7.

KEEP CHILDREN AWAY. All visitors should be kept a

safe distance from work area.

8.

MAKE WORKSHOP KIDPROOF—with padlocks, master

switches, or by removing starter keys.

9. DON’T FORCE TOOL. It will do the job better and be

safer at the rate for which it was designed.

10. USE RIGHT TOOL. Don’t force tool or attachment to

do a job it was not designed for.

11. WEAR PROPER APPAREL. No loose clothing or jewelry

to get caught in moving parts.

12.

13.

14

.

15.

16.

17.

18.

USE SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty.

SECURE WORK. Use clamps or a vise to hold work,

when practical. It’s safer than using your hand, frees

both hands to operate tool.

DON’T OVERREACH. Keep your proper footing and

balance at all times.

MAINTAIN TOOLS IN TOP CONDITION. Keep tools

sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

DISCONNECT TOOLS before servicing and when chang

ing accessories such as blades, bits, cutters.

USE RECOMMENDED ACCESSORIES. Consult owner’s

manual. Use of improper accessories may be hazardous.

AVOID ACCIDENTAL STARTING.

off before plugging in cord.

Make sure switch is

GROUNDING

These units are equipped with an outlet box

mounted on the back of the unit for permanent

wiring, as required by Underwriters Laboratories.

Wiring diagrams are pasted to the underside of

the base. To insure proper wiring & “grounding”

of tool, have connection made by a qualified

electrician.

LUBRICATION

This tool is equipped with lubricant sealed ball

bearings which require no further lubrication for

the life of the bearing.

MOTOR

Four pole capacitor start induction motor,

rel cage rotor.

Squir-

Cat

Rated

RPi

No. Phase HP

Cycles

@ 115 V.

Mo Load

Voltage, A.C.

4330 1

1

50/60

14.6/13

1500/1800

115 Volts

4330-01 1

1

50/60

14.6/13

1500/1800

220 Volts

4335 3

1

50/60

14.6/13

1500/1800

220/440

Reconnectable

CHANGING

WHEELS

Remove 4 screws holding wheel guard cover.

Loosen and remove hexagon nut. (Nut on left

wheel has left hand threads, nut on right wheel

has right hand threads) and clamp washer. Re

move wheel. To reassemble, reverse above steps.

Do not overtighten nut. Wheel size 10" O.D.,

3

/

4

" I.D., 1" Width.

ACCESSORIES

No. 34575 One Shatter-Proof Eye Shield . . . Fastens per

manently to Bench Grinder. Adjusts quickly to various posi

tions to suit operator. Not illuminated. (Replacement glass,

No. 34576).

No. 19115 Cutter Wheel Dresser . . . Has spare set of cutter

wheels. Dresses wheels quickly for fast grinding.

No. 21961 Diamond Dresser . . . Produces an accurate,

smooth face for finish grinding.

No. 53536 Pedestal . . . Holds grinder at convenient height.

Has detachable water pot. Height: 31%"; Base: 16 square.

Grinding Wheels (10" Diam. x 1" Face x %" Hole):

No. 10274 Specification A24Q6V, Type 1

No. 10275 Specification A46N6V, Type 1

Wire Wheel Brushes (10" Diam. x 1%" Face x %" Hole:

No. 21407

.014 Wire Diam. (30 Gage)

No. 27012

.0118 Wire Diam. (33 Gage)

Cotton Buffing Wheels (10" Diameter x ^/

4

" Hole):

No. 26873

%" Wide

No. 26876

V4" Wide

CAUTION:

Recommended accessories for your Bench

Grinder are listed above. The use of any other accessory

might be more hazardous.

ADDITIONAL GRINDER SAFETY RULES

1. Always wear safety glasses or other eye protection when

4.

operating this tool, and eye shields, mounted on the

wheel guards, are strongly recommended.

2. Replace a cracked wheel immediately. Handle grinding

5.

wheels carefully to avoid bumping or dropping. DO NOT

use a grinding wheel that has been dropped. Before

using, inspect each grinding wheel for cracks or flaws

6.

and if these are evident, discard the wheel.

Before mounting a new wheel, be sure that it is marked

with an R.P.M. that is the same as, or higher than, the

no-load speed of the grinder as marked on the name

plate. Do not overtighten wheel nut. Use only flanges

furnished with this grinder.

Never start a grinder with anyone, including the operator,

standing in line with the wheel. After installing a replace

ment wheel, stand to one side and allow it to revolve

freely for about one minute.

Do not grind on the sides of grinding wheels unless they

are the special wheels designed specifically for this

purpose.

Use of any other accessory or attachment other than

those specified might create a hazard for the operator.

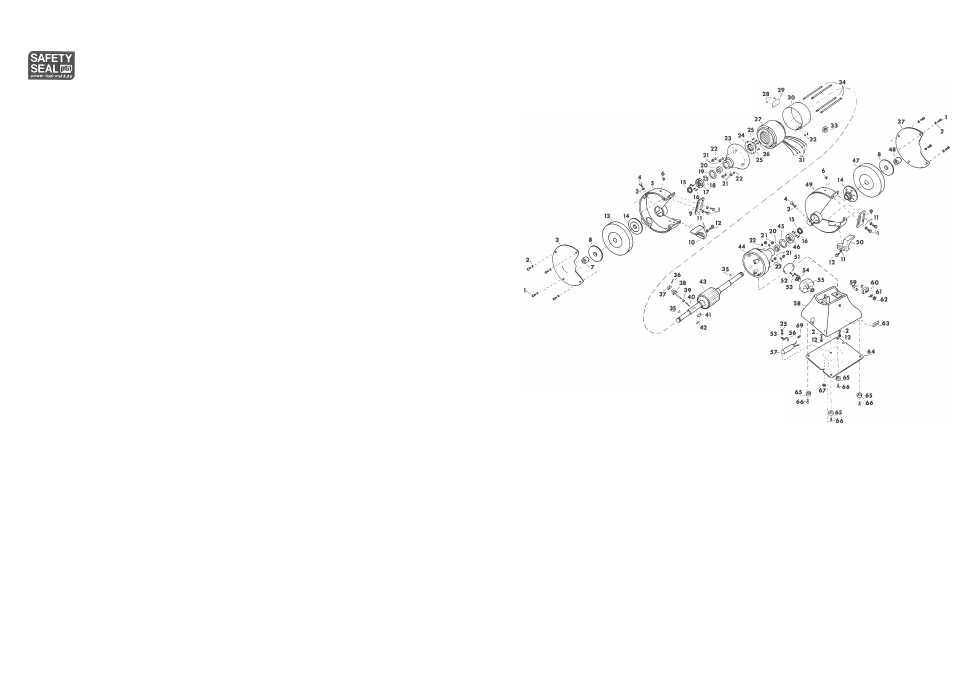

IO" BENCH GRINDER

Cat- No. 4330, TY. 1,11S¥, 1 Ph.

Cat. No. 4330-01, TY. 1, 220V, 1 Ph.

Cat. No. 4335, TY. 1, 220/440V, 3 Ph.

1

11467

5/16-24

X

% Hex head screw (12)

2

393

5/16 Lock washer (12)

3

982372

Guard cover (2)

4

6947

5/16-24 X 1 Hex head screw

(2)

5

982370

Wheel guard

6

13345

V

a

-28

X

Vz

Round head machine

screw and washer (2)

7

10257

3

/

4-10

Hex nut (L.H.)

8

982064

Outer clamp washer (2)

9

15726

Spark shield (2)

10

15709

Tool rest (L.H.)

11

801

Flat washer (6)

t36

16623

Pin

12

5531

5/16-18

X

1 Hex head screw (4)

t37

34246

Brush

13

10274

Grinding wheel (coarse)

t38

982954

Brush

carrier

14

982063

Inner clamp washer (2)

t39

17022

Sleeve

15

15711

Felt washer (2)

■ t40

17020

Brush spring

16

367

10-32 x % Fillister head

t41

17024

Weight

machine screw (8)

t42

17021

Pin

17

15705

Bearing cap

43

982952

Rotor

18

15717

Spring washer

44

19628

End

housing

19

15722

Gasket

45

19624

Gasket

20

15740

Bali bearing (2)

46

15706

Bearing cap

21

405

1

/

4-20

Hex nut (8)

47

10275

Grinding wheel (mediunr

22

416

1/4

Lock washer (8)

48

10256

?4-10

Hex nut (R.H.)

23

15698

End housing

49

982371

Wheel guard

t24

982927

Centrifugal switch (stationary)

60

15710

Tool rest (R.H.)

t25

375

10-32

X 3/8

Round head screw (3)

51

34521-01

Cover plate

t26

20406

6-32

X

3/16 Terminal screw (2)

52

374

10-32 X 5/8 Round head

27

19664-61

Stator 115v. 1 phase

machine screw (2)

19664-65

Stator 220v. 1 phase

53

417

#10

Lock washer (3)

19664-75

Stator 220/440V. 3 phase

54

54691

Cord clamp and

nut

28

14002

Rivet (2)

55

34522-01

Outlet box

29

61466

Nameplate

t56

19325

Condenser clamp

30

15719

Stator Band

t57

30390

Condenser

31

34289

Lead terminal (6)

58

995935

Base

32

22977

Drive screw (2)

59

2379

Terminal screw (4)

33

58122

Hex sticker

60

it36965

Switch (single phase)

34

982977

Stud (4)

I

25920

Switch (3 phase)

35

26587

Woodruff key (2)

61

19326

Indicating plate

t985202

Centrifugal switch (rotating)

62

24701

Hex nut

includes items 36 - 42

63

72418

Caution Sticker

64

15712

Base plate

65

15723

Foot (4)

66

372

1

/

4-20

X

3/j. Round head machine

screw (4)

67

406

10-32 Hex nut

68

57314

Wiring diagram label 1 phase

all voltages

69

67315- 01 Wiring diagram label 3 phase

220 volts

67316- 01 Wiring diagram label 3 phase

440 volts

32114 Connector

Special part not shown for 3 phase

grinders, No. 4335

982318

Insulator (2) (3 phase only)

(switch)

Connection Diagrams

f45699

Connection Diagram

(single phase)

45700-01 Connection Diagram (3 phase)

37485

Locking Ring for #36965 switch

only (single phase only)

fOmit for 3 phase

BULLETIN No. 2928-1