Additional, Operating, Instructions – Black & Decker ELU 3375 User Manual

Page 4: Double insulation, Extension cords, Switch, Fv'x m, Additional operating instructions

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

TRIGGER SWITCH

Additional

Operating

Instructions

PRECAUTIONARY

INSTRUCTIONS

1. CAUTION—Blades are

extremely sharp. Avoid body

contact.

2. Read owner’s manual thoroughly

before using tool.

3. Voltage must agree with specific

data on the nameplate.

4. Be sure the switch is in “OFF”

position before connecting tool to

power supply.

5. Switch tool “OFF” immediately if

tool should become jammed in

work.

6. Be sure tool is disconnected from

power source when cleaning,

adjusting, or doing maintenance

on the tool.

7. Planer should be properly set and

adjusted before turning unit on.

8. Use specified replacement parts

only.

9. Maintain tool with care. Follow

instructions for changing blades.

10. Store tool in a clean dry place

after disconnecting from power

source.

11. Do not force tool, allow tool to

perform as it was designed. Use

only sharp blades.

12. Do not allow visitors to approach

work area, especially children.

13. Do not cover the air vents on the

tool. Vents must be kept open for

motor cooling.

14. Do not leave tool unattended

without disconnecting from power

source.

15. Do not yank cord when

disconnecting tool from power

supply.

16. Do not carry the tool by power

cord.

17. Do not carry planer with your

finger on the switch.

18. Do not lay tool down on shoe

when the blades are exposed.

19. Do not allow planer blade to

contact metal objects. This may

chip or damage blades.

NOTE—Do not use chipped or

damaged blades.

20. Do not obstruct side chip chute.

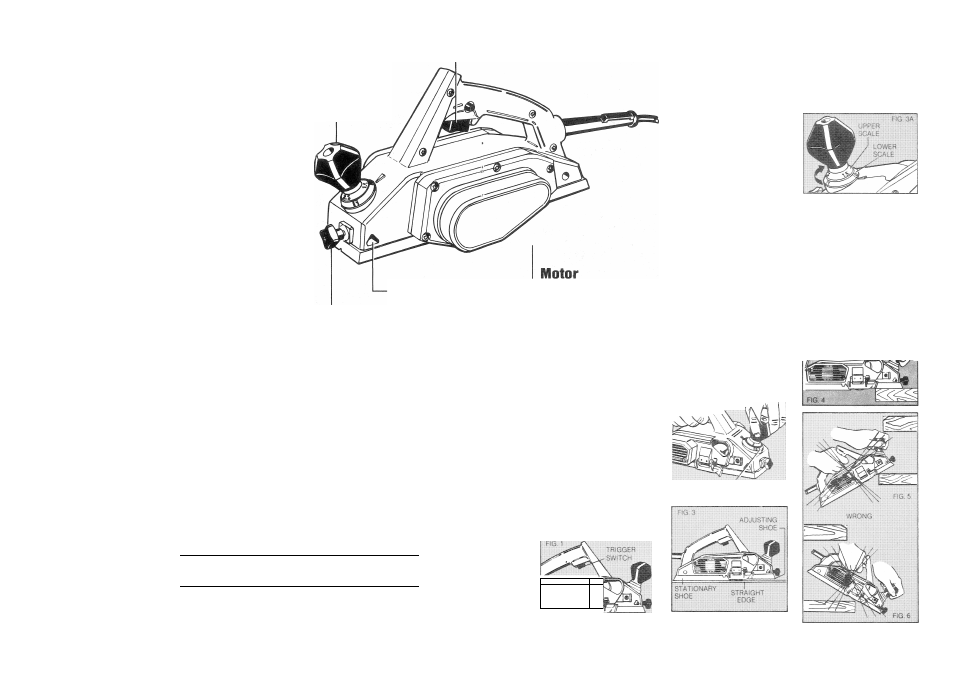

SHOE ADJUSTMENT

KNOB

FRONT BORE

21. Always use fence unless surface

planing. Use extreme caution,

stay clear of drive belt and cutter

location.

22. Turn off tool immediately after

finishing cut.

SAVE THESE INSTRUCTIONS

Double Insulation

Your unit is DOUBLE-

INSULATED to give you added

safety. This means that it is

constructed throughout with TWO

separate “layers” of electrical

insulation or one DOUBLE thickness

of insulation between you and the

tool’s electrical system.

Tools built with this insulation

system are not intended to be

grounded. As a result, your tool is

equipped with a two-prong plug which

permits you to use extension cords

without concern for maintaining a

ground connection.

NOTE; DOUBLE INSULATION

does not take the place of normal

safety precautions when operating

this tool. The insulation system is for

added protection against injury

resulting from a possible electrical

insulation failure within the tool.

CAUTION: When servicing all

tools. USE ONLY IDENTICAL

REPLACEMENT PARTS. Repair or

replace damaged cords.

Extension Cords

Double insulated tools have 2 wire cords, and can be used with 2 wire or 3

wire extension cords. Only round jacketed extension cords should be used, and

we recommend that they be listed by Underwriters Laboratories (U.L.). If the

extension will be used outside, the cord must be suitable for outdoor use. Any

cord marked as outdoor can also be used for indoor work. The letters “WA” on

the cord jacket indicate that the cord is suitable for outdoor use.

An extension cord must have adequate wire size (AWG or American Wire

Gauge) for safety, and to prevent loss of power and overheating. The smaller

the gauge number of the wire, the greater the capacity of the cable, that is 16

gauge has more capacity than 18 gauge. When using more than one extension

to make up the total length, be sure each individual extension contains at least

the minimum wire size.

To determine the minimum wire size required, refer to the chart below;

CHART FOR MINIMUM WIRE SIZE (AWG) OF EXTENSION CORDS

FENCE

ROD TIGHTENING

KNOB

NAMEPLATE

RATING-AMPS

TOTAL EXTENSION CORD LENGTH-FEET

25

50

75

100

125

150

175

200

0

-

10.0

18

18

16

16

14

14

12

12

10.1

-

13.0

16

16

14

14

14

12

12

12

13.1

-

15.0

14

14

12

12

12

12

12

—

Before using an extension cord, inspect it for loose or exposed wires,

damaged insulation, and defective fittings. Make any needed repairs or replace

the cord if necessary.

lb

Your ELU tool IS powered by an

ELU-built motor. Be sure your power

supply agrees with the nameplate

marking.

Volts 50/60 Hz or “AC only”

means your tool must be operated

only with alternating current and never

with direct current.

Voltage decrease of more than

10% will cause loss of power and

overheating. All ELU tools are factory

tested; if this tool does not operate,

check the power supply.

Switch

Always pick up your planer by the

handle before depressing the switch.

NOTE; Always remember to keep free

hand away from bottom of planer. The

planer IS started by depressing the

trigger in the handle. To turn the

planer off, release the trigger (Fig. 1),

Allow time for the blades to stop

turning before setting the tool down.

To lock the planer “ON” squeeze

the trigger and hold it while you press

in the trigger locking button in the

handle next to the trigger. Hold the

locking button in while you release the

trigger and the tool will continue to

run. To release the trigger lock,

squeeze and release the trigger once.

------

UNPLUG PLANER

The adjustment of the desired

depths is accomplished by turning

shoe adjustment knob.

First, set the planing depth to zero

by placing a straight edge along the

bottom of the tool and adjusting the

front shoe until the front and stationary

shoes are of equal height (Fig. 3), (At

this point, no light will pass between

the shoes and the straight edge.)

When both the adjustable shoe

and the stationary shoe are even, the

adjusting knob should read zero on

the lower scale, as shown in Figure

3A. From that starting point, rotate the

adjusting knob clockwise to raise the

adjustable shoe. Each full revolution of

the adjusting knob raises the shoe

1/16” (1.5 mm) and the scale on the

knob is marked in .5 mm graduations.

On the first revolution of the knob,

read the graduations on the bottom of

the knob and on the second

revolution, read the upper graduations,

as shown in Figure 3A. When you

have adjusted the planer, practice on

a piece of scrap wood until you are

comfortable with the tool.

SHOE

f

KNOBJ

fV'X M

With one hand holding the handle,

place the front shoe on the work,

making certain blades are not

touching the work. Put pressure on the

handle so that the front shoe is

absolutely flat on the work (Fig. 4).

Start to plane with motor running at full

speed. NOTE; Several shallow

passes will produce a smoother

surface than one deep one.

In the beginning and in the end of

planing, be especially careful to keep

your planer flat on the work (Fig. 5 & 6).

A

■

. .

■/.