Drilling in masonry, Side handle, Chuck key holder – Black & Decker Thunder Volt 1801 User Manual

Page 5: Chuck removal, 1804 3/8" scrudrill, 1803 3/8" hammer drill

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Drilling In Masonry

Use carbide tipped masonry bits at

low speeds. Keep even force on the drill

but not so much that you crack the brittle

materials. A smooth, even flow of dust

indicates the proper drilling rate.

Side Handle

CAUTION: Always use side handle

when provided and hold tool with both

hands.

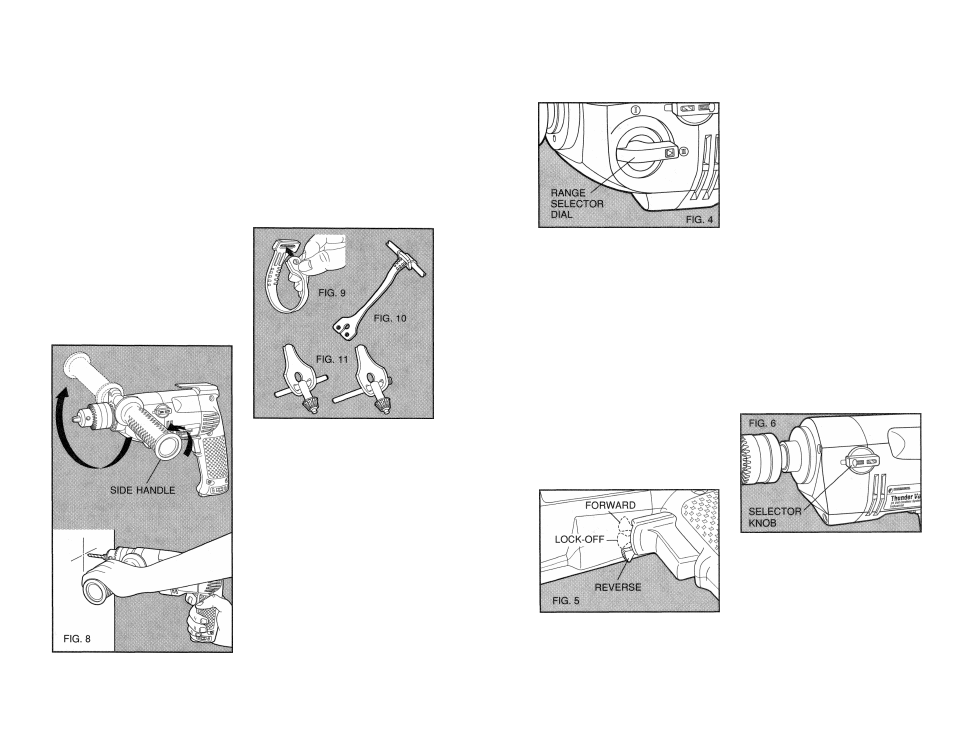

The side handle clamps to the front

of the gear case as shown in Figure 8

and can be rotated 360 degrees to permit

right or left hand use. Loosen the handle

(counterclockwise) to loosen the clamp

and rotate handle to desired position.

Tighten handle.

Chuck Key Holder

1. Push double-hole end of Holder

through slot in other end of Holder

(Figure 9).

2. Slip loop over electric plug and draw

loop tight around cord (Figure 10).

3. Push ends of Chuck Key Handle

through two holes in end of Holder

(Figure 11).

Chuck Removal

(Figures 12 and 13)

1. Place chuck key in chuck as shown

in Figure 12. Using a wooden mallet

or similar object, strike key sharply

in a CLOCKWISE direction. This

will loosen screw inside chuck.

2. Open chuck jaws fully, insert

screwdriver (or 3/16" hex wrench if

required) into front of chuck

between jaws to engage screw

head. Remove screw by turning

clockwise (left-hand-thread).

3. Place key in chuck as shown in

Figure 13. Using a wooden mallet

or similar object, strike key sharply

in a COUNTER-CLOCKWISE

direction. This will loosen chuck so

that it can be unscrewed by hand.

After selecting the desired range, the

1803 and the 1802 dual speed tools will

operate the same as the standard

variable speed reversing tools.

The Variable Speed Trigger

Switch permits speed control — the far

ther the trigger is depressed, the higher

the speed of the Drill. NOTE: Use lower

speeds for starting holes without a

center punch, drilling in metal or

plastics, driving screws, drilling

ceramics, or mixing paint. Higher

speeds are better for drilling wood and

composition boards, and for using

abrasive and polishing accessories.

The reversing lever can be used to

shift the tool into reverse for backing out

screws and withdrawing drill bits from

tight holes. To switch the tool from

forward to reverse, turn off the tool and

move the reversing lever shown in Figure

5 to the left, as viewed in the figure.

The reversing lever performs two

functions; it reverses the tool and it locks

the tool off. The center position is "lock-

off” and should be used whenever the

tool is put away or left unattended (refer

to Figure 5).

After any reversing operations, return

the lever to the forward position.

1804 3/8" Scrudrill

The Scrudrill is a combination drill

and screwdriver that you'll find to be a

great time saver.

To use this tool as a drill, rotate the

selector knob shown in figure 6 so that

the pictured drill bit is toward the front of

the tool. Use the drill as you would any

drill.

To select the screwdriving mode,

rotate the selector knob so that the

pictured screw is toward the front of the

tool as shown in the figure. In this mode

the motor will run when the trigger is

squeezed but the chuck will not turn until

you push in on the tool and engage the

clutch. This enables you to locate the

screwdriver bit in the screw without

turning the tool off.

Try a few test screws in scrap

material until you develop a "feel" for the

Scrudrill.

1803 3/8" Hammer Drill

The Hammer Drill is a drill especially

made for drilling holes in masonry where

a slight impacting action is required. The

Hammer Drill, as its name implies, can

also be used as a standard drill.

To operate as a drill, rotate the

selector knob shown in Figure 7 so that

the pictured drill bit is toward the front of

the tool. Operate as you would any

standard drill.