Using the depth stop, Workpiece and work area set up, Safety opera tion maintenance setup – Chicago Electric Power Tools 12" DOUBLE-BEVEL SLIDING COMPOUND MITER SAW WITH LASER GUIDE 69684 User Manual

Page 12

Page 12

For technical questions, please call 1-800-444-3353.

Item 69684

Using the Depth Stop

If a kerfing or rabbet cut which does not cut through the workpiece is desired,

use the Depth Stop Bolt to control the depth of the cut.

WARNING! Only adjust the front Bolt. The rear Bolt is used to prevent the Blade from

cutting the table during normal cutting. Do not adjust the rear Depth Bolt.

1. Unlock the Head Lock-down, see page 9.

2. Raise the saw head assembly.

3.

Push the Depth Stop to the left to

use the Depth Stop Bolt setting.

4. Pull down on the saw head to

check the current setting.

5. To change the setting, first loosen the knurled

Depth Stop Nut on the Depth Stop Bolt.

Turn the Depth Stop Bolt clockwise to decrease

depth and counterclockwise to increase depth.

Tighten the Depth Stop Nut after adjustment.

6.

If needed, push the Depth Stop to the

right to temporarily disable it.

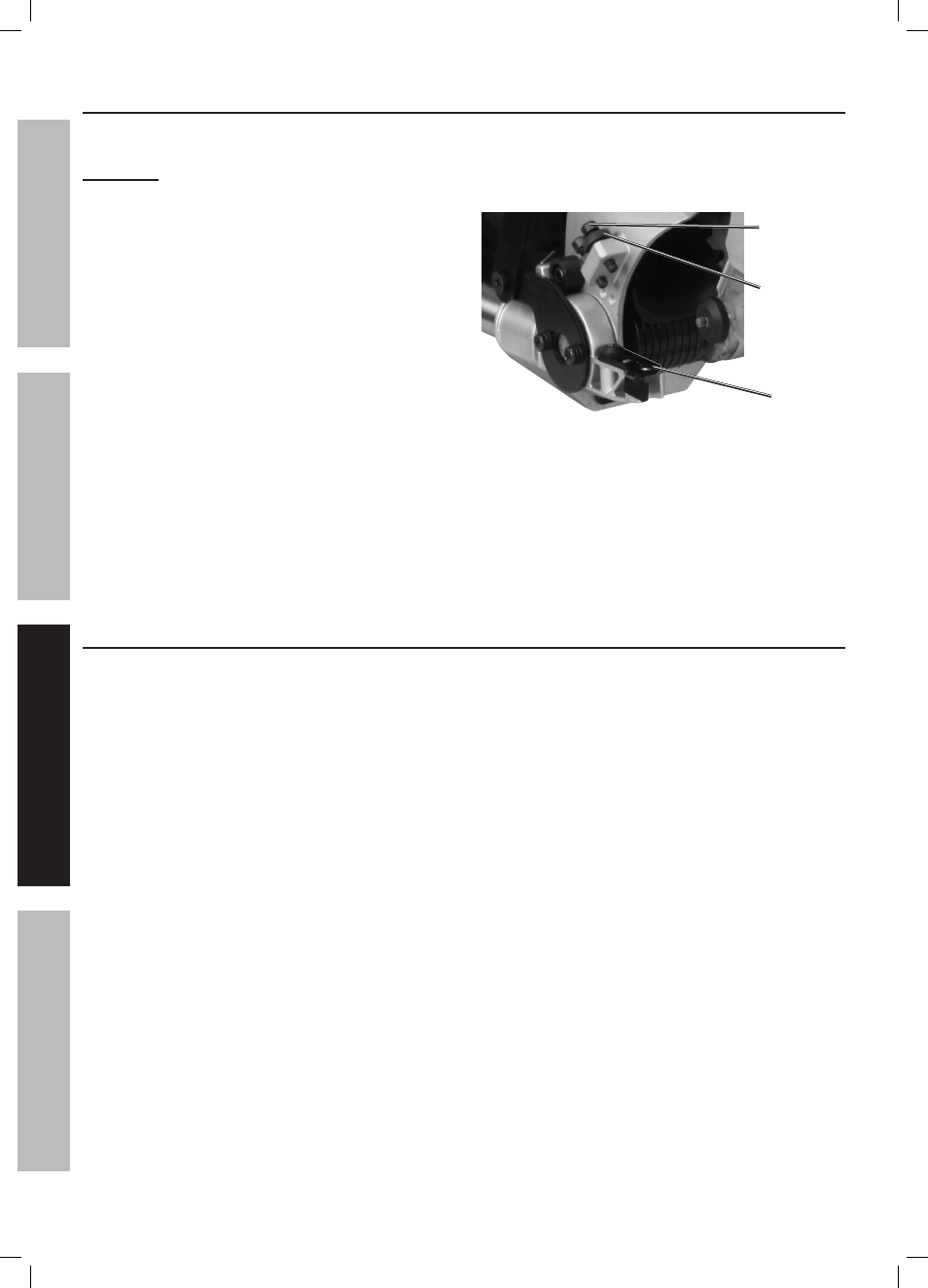

Depth Stop

Bolt (136)

Depth Stop

Nut (137)

Depth

Stop (44)

Figure D

Workpiece and Work Area Set Up

1. Designate a work area that is clean and well-lit.

The work area must not allow access by children

or pets to prevent injury and distraction.

2. Route the power cord along a safe route to reach

the work area without creating a tripping hazard or

exposing the power cord to possible damage. The

power cord must reach the work area with enough

extra length to allow free movement while working.

3. Allow room on both left and right of

saw for extended workpieces.

4. Use a saw table, saw stand or other means to

support the workpiece. Mount the Miter Saw

so that the surface is level to the ground, and

additional supports provide a surface on the

same level as the saw table. If the work surface

and any workpiece supports are not level, and

on the same level, unwanted bevel angles will

appear in the cuts resulting in poor joinery.

5. Secure workpieces to the saw table using the Clamp

or other clamping devices (not included). Securing

the workpiece will provide safety by preventing kick

back and by removing the need to hold workpieces

near the blade by hand. Clamping the workpiece

will also improve cutting accuracy by preventing the

workpiece from moving during the cutting operation.

SAFETY

OPERA

TION

MAINTENANCE

SETUP